High-speed gas-arc composite thermal spraying method and spray gun therefor

A thermal spraying and gas technology, applied in coating, spraying device, melting spraying and other directions, can solve the problem of high operating cost, achieve the effect of high ignition energy, reduce oxidation, and reduce serious oxidation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

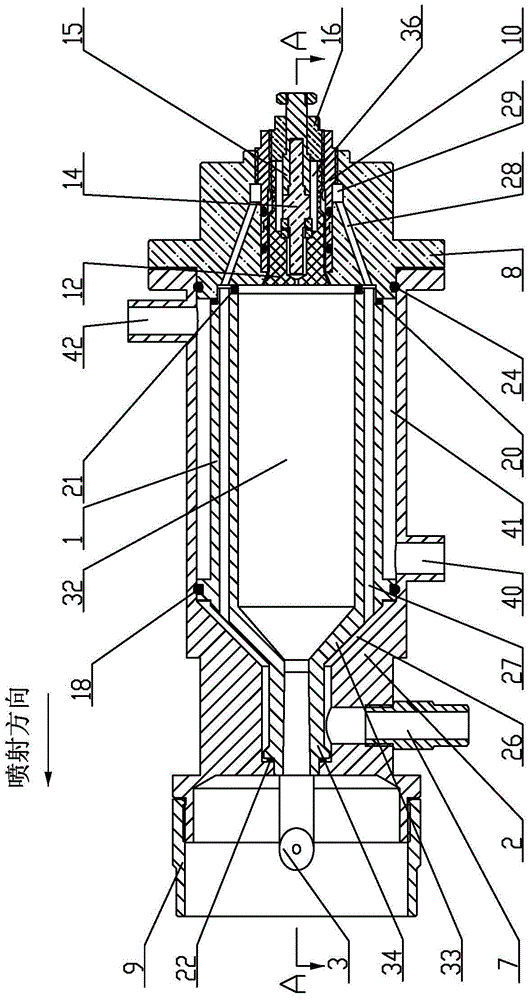

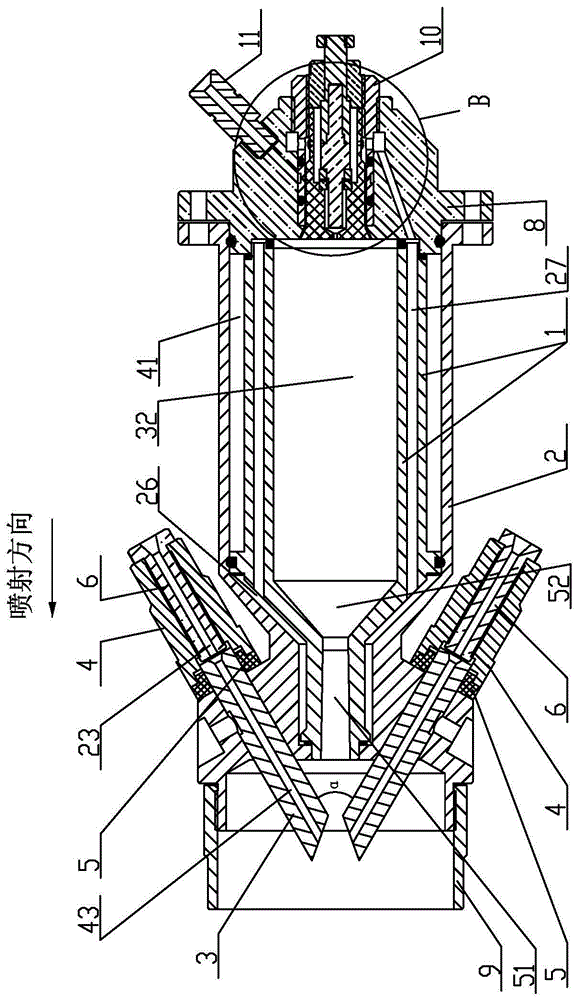

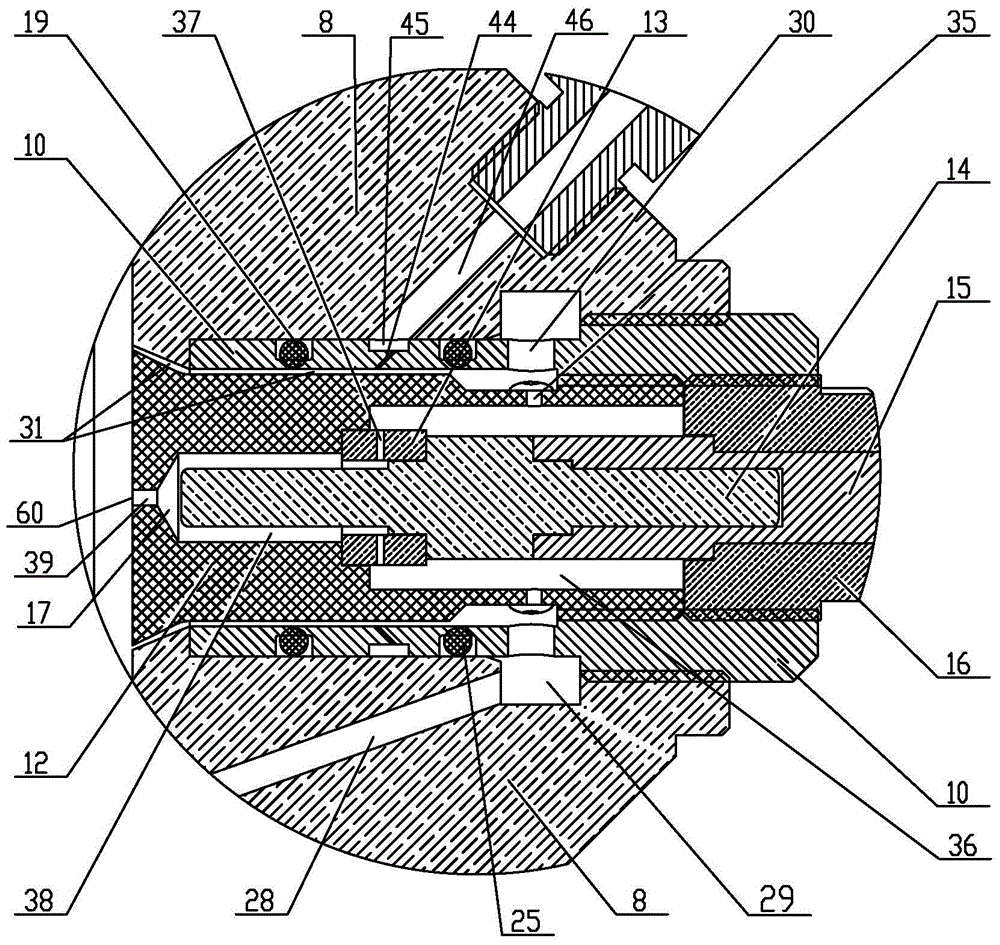

[0022] The present invention proposes a kind of high-speed gas-electric arc composite thermal spraying method, and it comprises the following steps:

[0023]1) By means of air plasma ignition, the mixture of kerosene and compressed air is ignited to form an annular high-speed jet oil-gas mixed flow, and the speed of the jetted oil-gas mixed flow can reach more than 100m / s;

[0024] 2) Make the oil-gas mixed flow continue to fully burn and accelerate, forming a gas whose speed is more than 1 times the speed of sound, and then spray it to the wire;

[0025] 3) The wire is energized and melted by arcing, atomized and accelerated under the action of supersonic gas jet, and deposited on the surface of the part to be sprayed to form a coating to complete the thermal spraying operation.

[0026] In the above-mentioned thermal spraying method of the present invention, the combined cooling of water and compressed air can be used to lower the temperature of the combusted oil-air mixed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com