A method for improving the selectivity of carbothermal reduction of laterite nickel ore

A laterite nickel ore and selective technology, applied in the metallurgical field, can solve the problems of limited promotion, unsatisfactory nickel-iron product quality, and lower nickel grade, etc., and achieve the effect of simple process flow, good nickel recovery effect, and improved grade effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

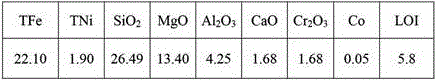

Embodiment 1

[0023] Fully mix the laterite nickel ore powder with a certain quality of sulfur-containing additives, and dry the agglomerates. Among them, the sulfur-containing additives contain sodium sulfate and sodium sulfide, and the total sulfur in the sulfur-containing additives and the total iron in the laterite nickel ore The mass ratio of the sulfur-containing additive is 0.15; the ratio of the mass of sodium sulfate and sodium sulfide to the total mass of the sulfur-containing additive is 0.6. Roasting at 1050°C for 60 minutes in a reducing atmosphere with a CO mass percentage of 40% yields a reduced product. After cooling, the reduced product is crushed and ground until 90% of it is smaller than 74nm, and then separated by magnetic separation. According to the test and analysis, the sulfidation rates of nickel and iron in the reduction products are 4.35% and 20.42% respectively, and the metallization rates of nickel and iron are 91.78% and 70.69% respectively. The grades of nicke...

Embodiment 2

[0025] Fully mix the laterite nickel ore powder with a certain quality of sulfur-containing additives, and dry the agglomerates. Among them, the sulfur-containing additives contain sodium sulfate, and the mass ratio of the total sulfur in the sulfur-containing additives to the total iron in the laterite nickel ore is 0.20; the ratio of the mass of sodium sulfate in the sulfur-containing additive to the total mass of the sulfur-containing additive is 0.8. Roasting at 1050°C for 60 minutes in a reducing atmosphere with 50% CO by mass, the reduced product was obtained. After cooling, the reduced product was crushed and ground until 90% of it was smaller than 0.074mm, and then separated by magnetic separation. According to the test and analysis, the sulfidation rates of nickel and iron in the reduction products are 4.82% and 25.23% respectively, and the metallization rates of nickel and iron are 90.96% and 66.85% respectively. The grades of nickel and iron in the obtained ferronic...

Embodiment 3

[0027] Fully mix the laterite nickel ore powder with a certain quality of sulfur-containing additives, and dry the agglomerates. Among them, the sulfur-containing additives contain sodium sulfide, and the mass ratio of the total sulfur in the sulfur-containing additives to the total iron in the laterite nickel ore is 0.23; the ratio of the mass of sodium sulfide to the total mass of sulfur-containing additives is 1.0. Roast at 1050°C for 50 minutes in a reducing atmosphere with a CO mass percentage of 50% to obtain a reduced product. After cooling, the reduced product is crushed and ground until 90% of it is less than 74nm, and is separated by wet weak magnetic separation. According to the test and analysis, the sulfidation rates of nickel and iron in the reduction products are 5.02% and 27.16% respectively, and the metallization rates of nickel and iron are 92.14% and 64.05% respectively. The grades of nickel and iron in the obtained ferronickel product are 12.05% and 81.46% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com