A kind of calcium nitrate environment-friendly drilling fluid and preparation method thereof

A drilling fluid and calcium nitrate technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of difficulty in running 339.7mm surface casing, frequent downhole accidents, and difficulty in hole cleaning, etc. The effect of wellbore stability, formation collapse prevention and gypsum contamination resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

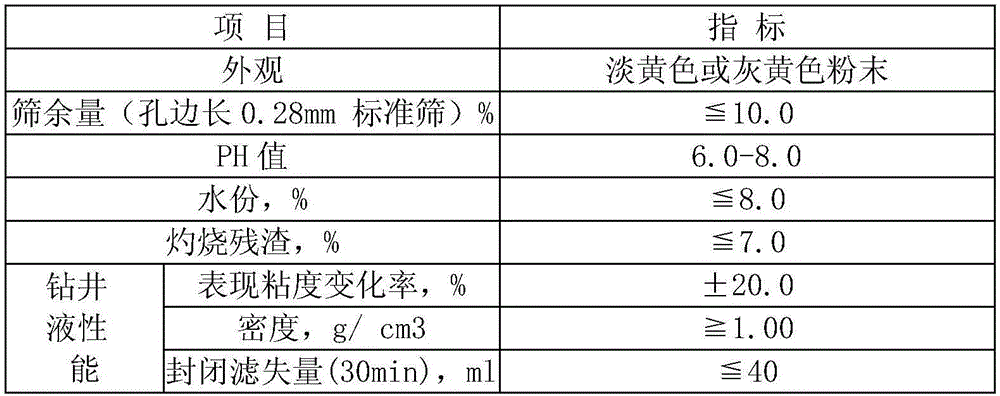

Image

Examples

Embodiment 1

[0027] Choose the calcium nitrate that mass percent is 3%, the xanthan gum of 0.3%, the low viscosity polyanionic cellulose of 0.5%, the sodium hydroxide of 0.1%, the preservative (formaldehyde or glutaraldehyde) of 0.03%, all the other are clear water and other raw materials,

[0028] 1) Fill the on-site slurry mixing tank with the above-mentioned clean water;

[0029] 2) Add 0.5% low-viscosity polyanionic cellulose and 0.3% xanthan gum to the clear water according to the above mass percentage, and fully stir and mix evenly;

[0030] 3) Add 3% calcium nitrate of the above-mentioned proportioning to the uniformly stirred mixture;

[0031] 4) Add 0.03% formaldehyde or glutaraldehyde in the above ratio to the mixture obtained in step 3), and stir to dissolve it;

[0032] 5) Add 0.1% sodium hydroxide in the above ratio to the mixed fluid obtained in step 4), and adjust the pH value to 7 to prepare drilling fluid.

[0033] 6) When the drilling fluid obtained in step 5) is used,...

Embodiment 2

[0041] Choose the calcium nitrate that is 5% by mass percentage, 1% xanthan gum, 1% low-viscosity polyanion cellulose, 0.3% potassium hydroxide, 0.1% formaldehyde, the rest are raw materials such as clear water,

[0042] 1) Fill the on-site slurry mixing tank with the above-mentioned clean water;

[0043] 2) Add 1% low-viscosity polyanionic cellulose and 1% xanthan gum to the clear water according to the above mass percentage, and fully stir and mix evenly;

[0044] 3) Add 5% calcium nitrate of the above-mentioned proportioning to the uniformly stirred mixture;

[0045] 4) Add 0.1% formaldehyde in the above ratio to the mixture obtained in step 3), and stir to dissolve it;

[0046] 5) Add 0.3% sodium hydroxide in the above ratio to the mixed fluid obtained in step 4), and adjust the pH value to 8.5 to prepare drilling fluid.

[0047] 6) When the drilling fluid obtained in step 5) is used, a plugging agent with a mass percentage of 0.3% is added to the obtained drilling fluid...

Embodiment 3

[0056] Choose the calcium nitrate that mass percent is 4%, the xanthan gum of 0.7%, 0.7% low-viscosity polyanionic cellulose, the potassium hydroxide of 0.2%, the formaldehyde of 0.07%, all the other are raw materials such as clear water,

[0057] 1) Fill the on-site slurry mixing tank with the above-mentioned clean water;

[0058] 2) Add 0.7% xanthan gum and 0.7% low-viscosity polyanionic cellulose to the clear water according to the above mass percentage, and fully stir and mix evenly;

[0059] 3) Add 4% calcium nitrate of the above-mentioned proportioning to the homogeneously stirred mixture;

[0060] 4) Add 0.07% glutaraldehyde in the above ratio to the mixture obtained in step 3), and stir to dissolve it;

[0061] 5) Add 0.2% sodium hydroxide in the above ratio to the mixed fluid obtained in step 4), and adjust the pH value to 7.5 to prepare drilling fluid.

[0062] 6) When the drilling fluid obtained in step 5) is used, a lost circulation agent with a mass percentage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com