Drilling fluid and application of ionic liquid in drilling fluid

A technology of ionic liquid and drilling fluid, which is applied in the field of drilling fluid, can solve the problems of unstable rheology and large fluid loss, and achieve the effect of reducing fluid loss and improving high temperature inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 drilling fluid

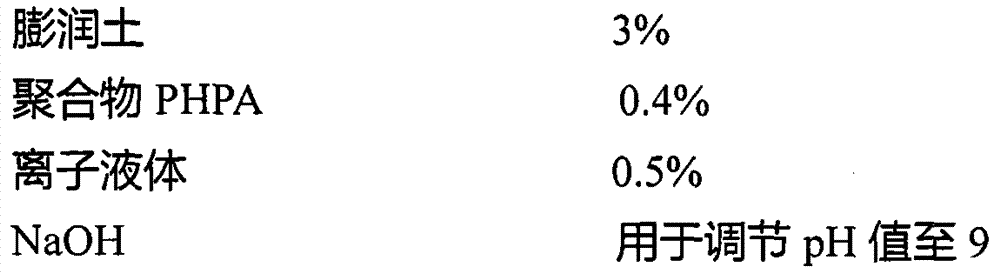

[0032] Drilling fluid comprising ionic liquid, preparation of a polymer-based drilling fluid comprising the following components: (mass percent)

[0033]

[0034] First configure a certain volume of drilling fluid with 3% bentonite, and pre-hydrate for 24 hours; at the same time, make the polymer into a certain concentration of glue, and add the aged drilling fluid according to the above ratio; add the ionic liquid according to the above ratio, and use Adjust the pH to 9 with NaOH.

[0035] In the experiment, the ionic liquid was 1-dodecyl-3-methylimidazole chloride (TIL) as the inhibitory experiment of drilling fluid anti-high temperature inhibitor, and the molecular formula was C 16 h 31 N 2 Cl, produced by Shanghai Chengjie Chemical Co., Ltd., with a purity of 99%.

Embodiment 2

[0036] Example 2 Drilling Fluid Inhibition Experiment

[0037] As an inhibitory test of drilling fluid anti-high temperature inhibitors. The commonly used methods for evaluating inhibition include shale rolling recovery test, shale expansion test and CST test.

[0038] This experiment is mainly used to detect the inhibitory ability of chemical treatment agents on the dispersion of shale. In the shale rolling dispersion experiment, according to the dispersibility of shale cuttings in the chemical reagent solution, the strength of inhibition of different chemical reagents on shale can be judged. The experiment uses the traditional inorganic clay expansion inhibitor KCl and the current new shale inhibitor polyamine as a comparative experiment. KCl can effectively inhibit clay swelling, but its high concentration will bring adverse effects on the environment, and at the same time, it will deteriorate the rheology of the drilling fluid system and increase the fluid loss. The pol...

Embodiment 3

[0070] Embodiment 3 The experiment that rheology and fluid loss influence

[0071] Drilling fluid rheology is a basic performance of drilling fluid, which plays a very important role in solving the following drilling problems: 1. Suspend and carry cuttings to ensure the cleanliness of the bottom and wellbore; 2. Affect the ROP, 3. Maintain borehole rules and ensure downhole safety; 4. Calculation of drilling annulus hydraulics. The ability of the drilling fluid to clean the wellbore depends not only on the hydraulic parameters of the circulation system, but also on the properties of the drilling fluid, especially the rheological properties. In order to effectively break rock at high shear rates and effectively carry cuttings at low shear rates, the drilling fluid is required to have a high dynamic-to-plastic ratio. According to field experience, it is more appropriate to control the dynamic plastic ratio at 0.36-0.48 (Pa / mPa.S) under normal circumstances. Rheology at high te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com