Super-levelling low-temperature curing powder coating for MDF

A technology of powder coating and low temperature, which is applied in the direction of powder coating, polyester coating, epoxy resin coating, etc. It can solve the problems of poor leveling, slow heat absorption, low thermal conductivity, etc., to reduce energy consumption, lower temperature and Time and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

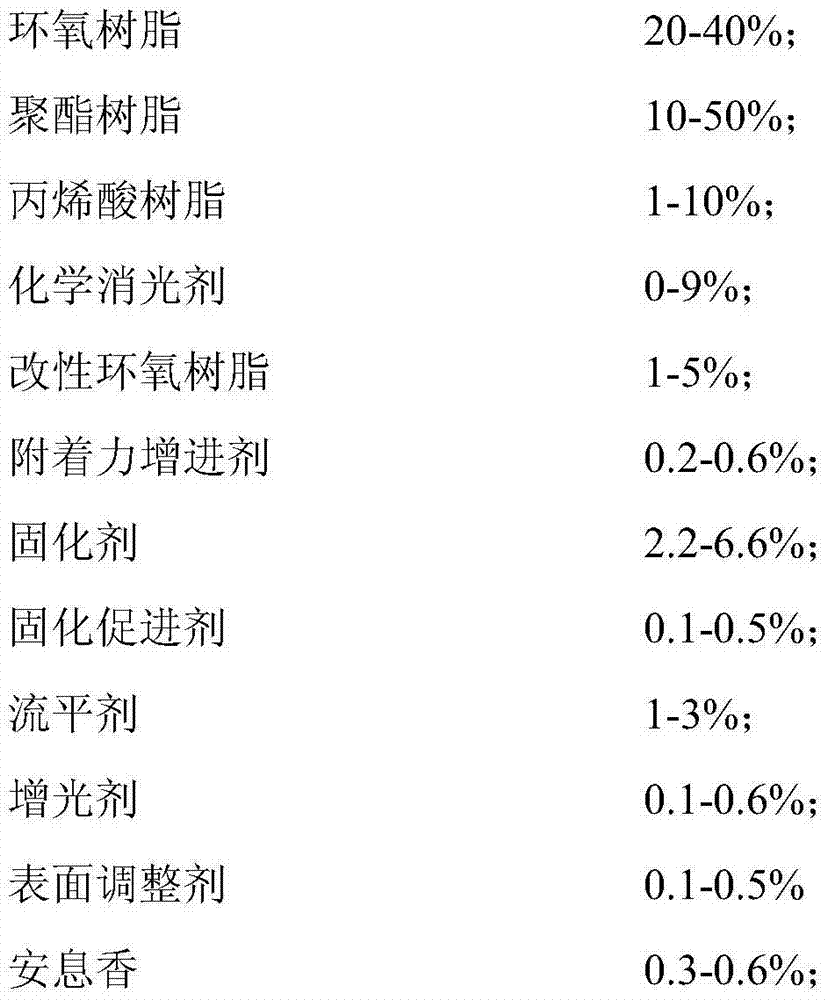

[0035] The MDF described in the present embodiment is made of the following raw materials in percentage by weight with super-leveling low-temperature curing powder coating:

[0036]

[0037] According to this formula, the low-temperature curing powder coating for MDF with super leveling and high gloss is prepared. After spraying, the curing condition is: curing at 130°C for 10 minutes.

Embodiment 2

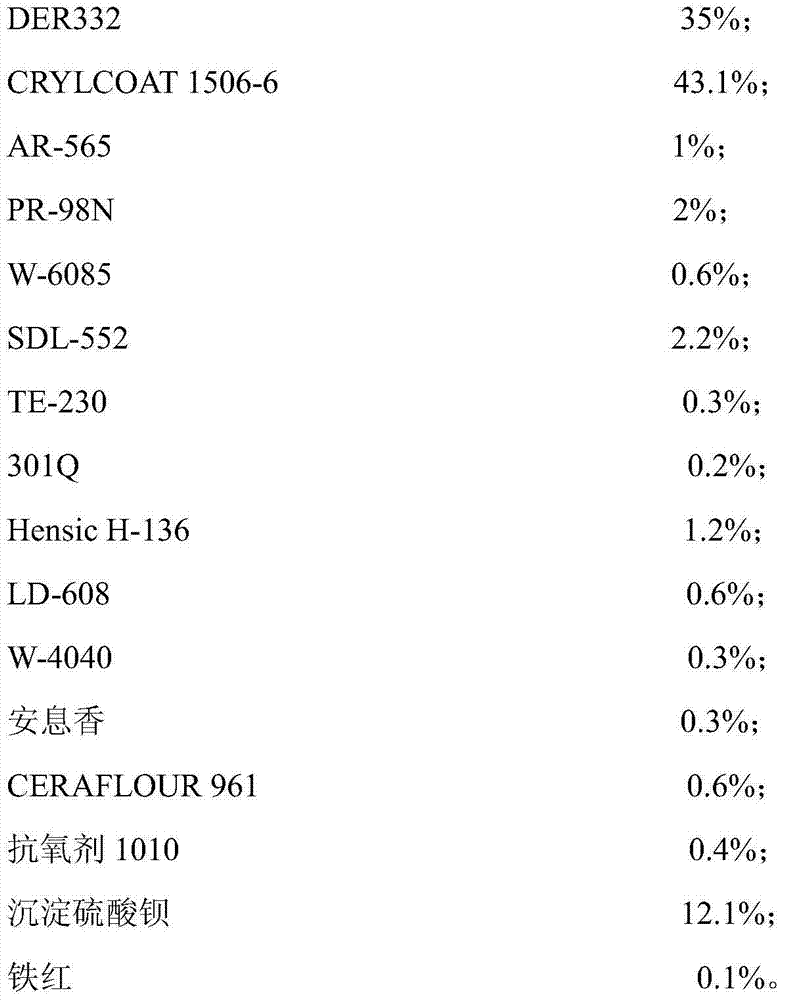

[0039] The MDF described in the present embodiment is made of the following raw materials in percentage by weight with super-leveling low-temperature curing powder coating:

[0040]

[0041] The low-temperature-curing powder coating for super-leveling and flat-gloss MDF prepared by using this formula is cured at 135°C for 9 minutes after spraying.

Embodiment 3

[0043] The MDF described in the present embodiment is made of the following raw materials in percentage by weight with super-leveling low-temperature curing powder coating:

[0044]

[0045]

[0046] The low-temperature curing powder coating for super-leveling and matt MDF prepared by using this formula is cured at 140°C for 8 minutes after spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com