Method for mixing polyester-ether macromonomers for preparation of polycarboxylic acid water reducer

A technology of polyether macromonomer and polycarboxylic acid, applied in the field of water reducing agent, achieves the effects of easy synthesis process, increased strength and good slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

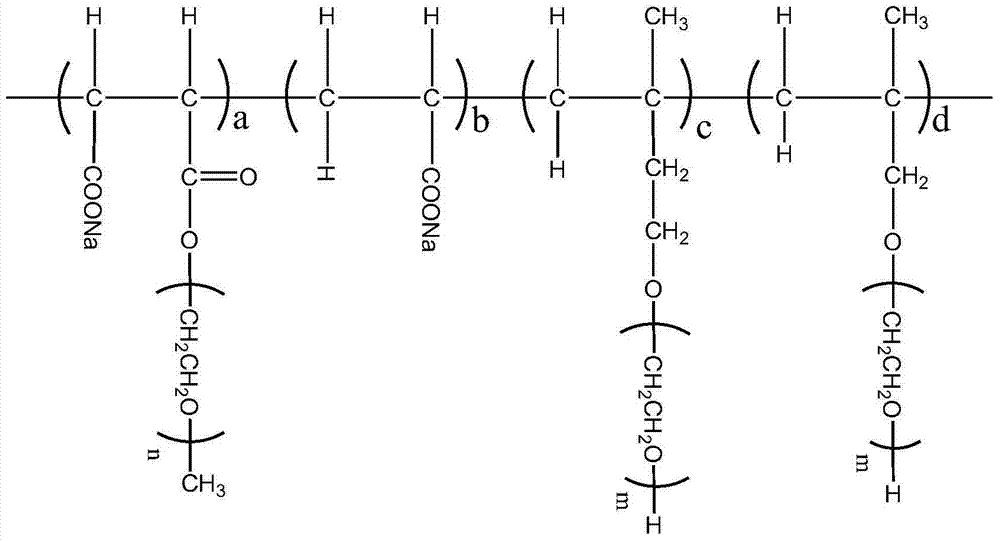

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of method for preparing polycarboxylate water-reducer by mixing polyester ether macromonomer, it comprises the following steps:

[0035] (1) Add polyethylene glycol and maleic anhydride with a molecular weight of 1000 into the reactor at a molar ratio of 1:1.1, and simultaneously feed nitrogen into the closed reactor at 40h / L for 30min to exhaust the air, and then nitrogen Reduce the flow rate to 20h / L, raise the temperature of the reactor to 58°C, wait until all the materials are melted, stir evenly, and make a mixed solution A;

[0036] (2) Stabilize the temperature at 50°C, slowly add 98% concentrated sulfuric acid of 0.3% by weight to the mixed solution A, stir for 8 minutes, raise the temperature to 100°C, and keep the temperature for 6 hours to obtain the mixed solution B;

[0037] (3) After the heat preservation is completed, the temperature is lowered to 48° C., the nitrogen gas is turned off, and water is added to the mixed solution B to ad...

Embodiment 2

[0042] Embodiment 2: a kind of method for preparing polycarboxylate water-reducer by mixing polyester ether macromonomer, it comprises the following steps:

[0043] (1) Polyethylene glycol and maleic anhydride with a molecular weight of 400 are added in the reactor with a mol ratio of 1:1.5, and nitrogen is passed into the closed reactor for 60 min at 50 L / h simultaneously to exhaust the air, and then the nitrogen Reduce the flow rate to 30L / h, raise the temperature of the reactor to 62°C, wait until all the materials are melted, stir evenly, and make a mixed solution A;

[0044] (2) Stabilize the temperature at 60°C, slowly add 98% concentrated sulfuric acid of 0.5% by weight to the mixed solution A, stir for 12 minutes, raise the temperature to 130°C, keep the temperature for 3 hours, and obtain the mixed solution B;

[0045](3) After the heat preservation is over, cool down to 52° C., turn off the nitrogen, add water to the mixed solution B, and adjust it into a maleic anhy...

Embodiment 3

[0050] Embodiment 3: a kind of method for preparing polycarboxylate water-reducer by mixing polyester ether macromonomer, it comprises the following steps:

[0051] (1) Polyethylene glycol and maleic anhydride with a molecular weight of 600 are added in the reactor with a mol ratio of 1:1.3, and nitrogen is passed into the closed reactor for 40min with 42L / h simultaneously to exhaust the air, and then the nitrogen Reduce the flow rate to 23L / h, raise the temperature of the reactor to 60°C, wait until all the materials are melted, stir evenly, and make a mixed solution A;

[0052] (2) Stabilize the temperature at 53°C, slowly add 98% concentrated sulfuric acid of 0.4% by weight to the mixed solution A, stir for 10min, the temperature rises to 110°C, and keep the temperature for 4.5h to obtain the mixed solution B ;

[0053] (3) After the heat preservation, turn off the nitrogen, cool down to 50°C, add water to the mixed solution B, and adjust it into a maleic anhydride polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com