Energy-saving high-performance dry-process calcium hydroxide production line

A calcium hydroxide, energy-saving technology, applied in the field of calcium hydroxide production, can solve the problems of environmental pollution, low production capacity, low calcium content in finished products, etc., and achieve the effects of high water content, reduced energy consumption, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

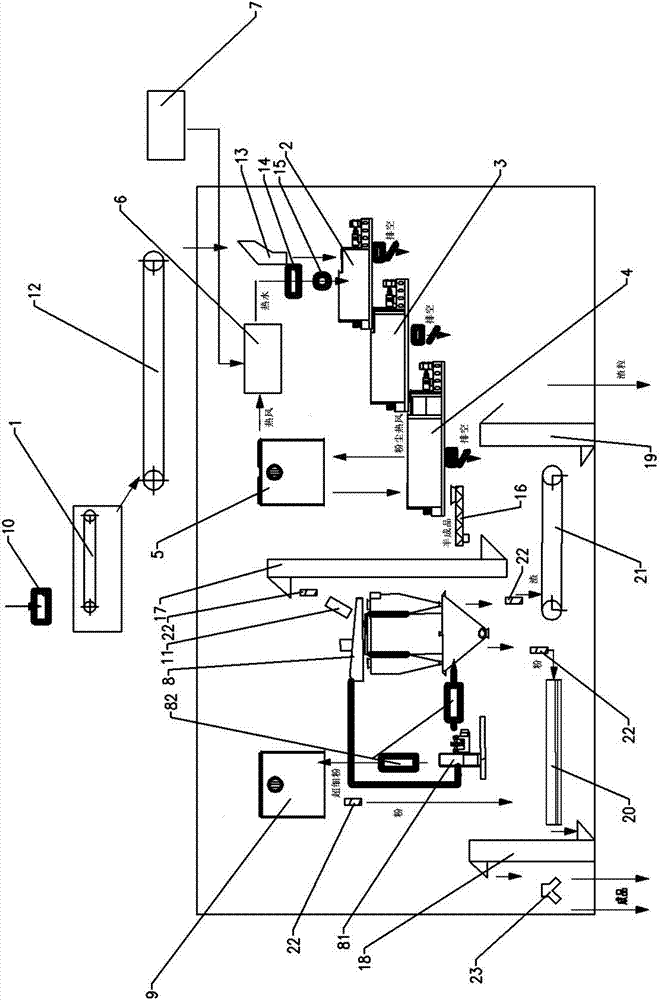

[0016] Embodiment 1: a kind of energy-saving type high-efficiency dry process calcium hydroxide production line, see figure 1 , including a material distribution device, a digestion device, a powder selection device, a water source supply device and a PLC control system, the material distribution device includes a material bin 10 and an electronic screw batching scale 1, and the electronic screw batching scale 1 is connected to the PLC control system signal , the outlet of the material bin communicates with the entrance of the electronic screw batching scale 1 through the conveying mechanism, and the outlet of the electronic screw batching scale 1 enters the digestion device through the belt conveyor 12 and the funnel chute 13. The electronic screw batching scale 1 provides information feedback to the PLC control system by measuring the volume and weight at the same time. The PLC control system calculates the estimated value of the purity of the raw material based on the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com