Discharge hopper for belt conveyor

A technology of belt conveyor and discharge hopper, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effect of slowing down the kinetic energy of materials, slowing down the load-bearing condition, and reliably buffering and absorbing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

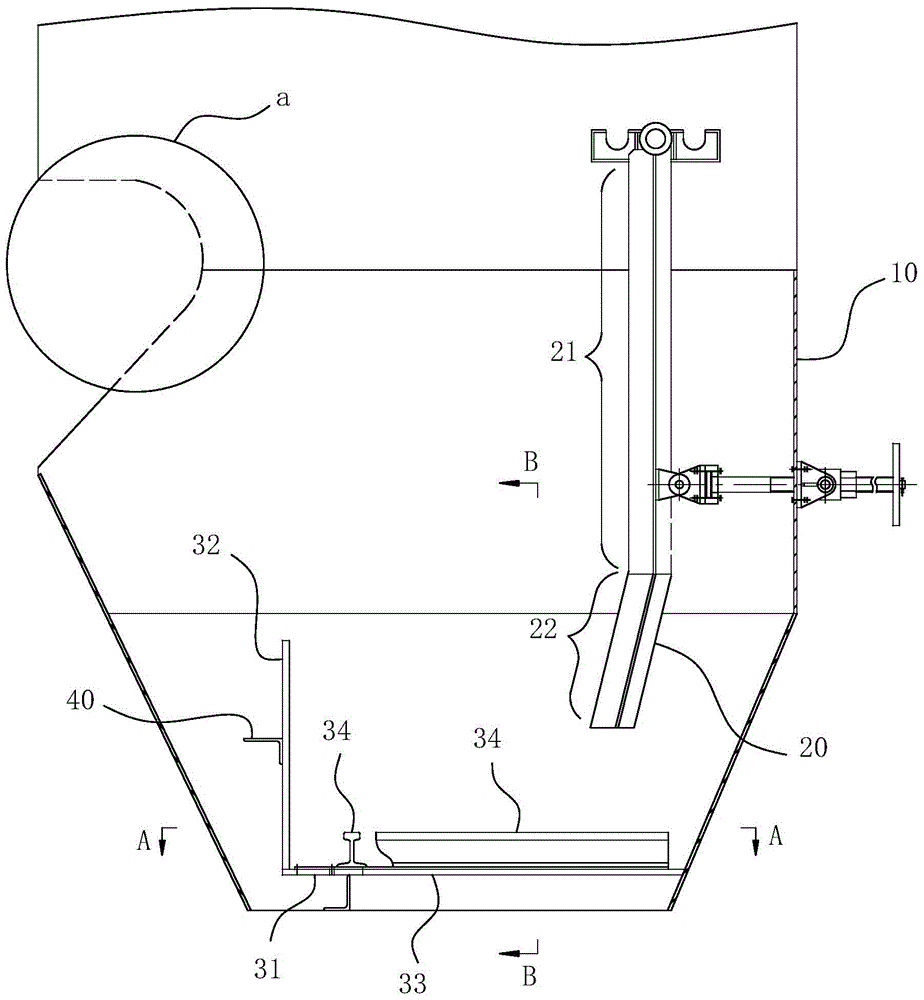

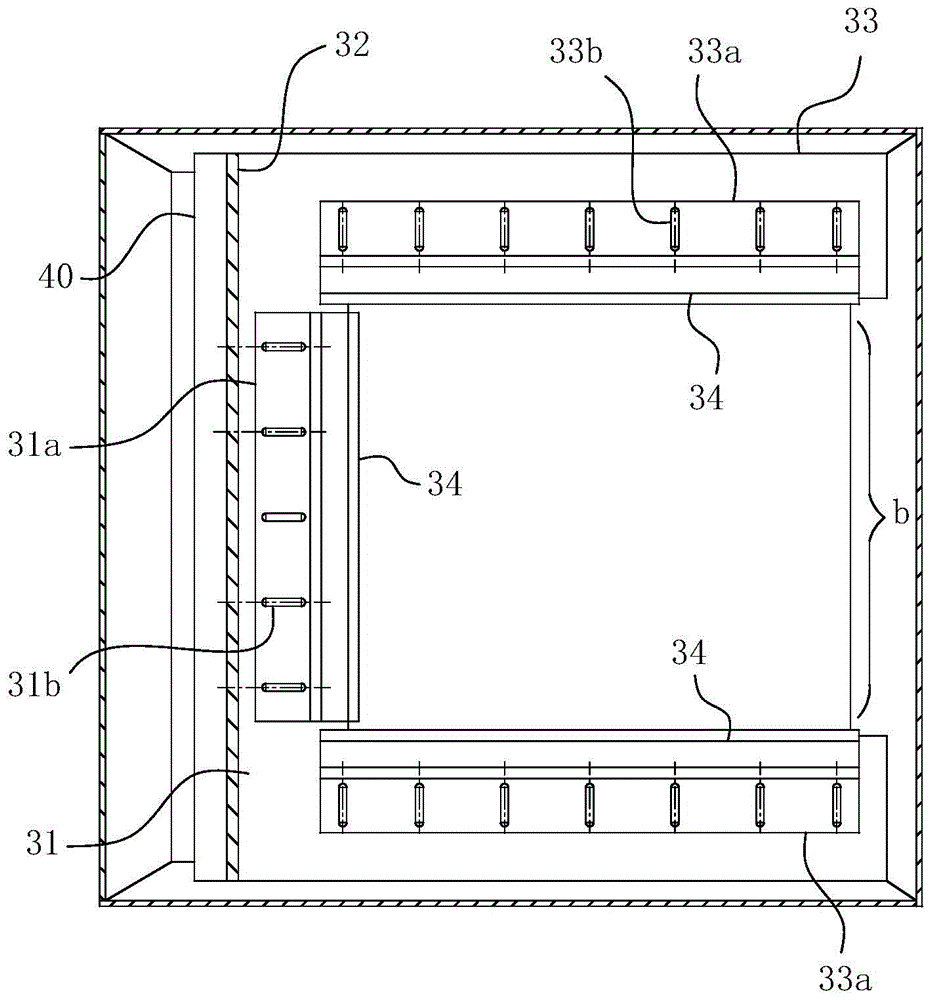

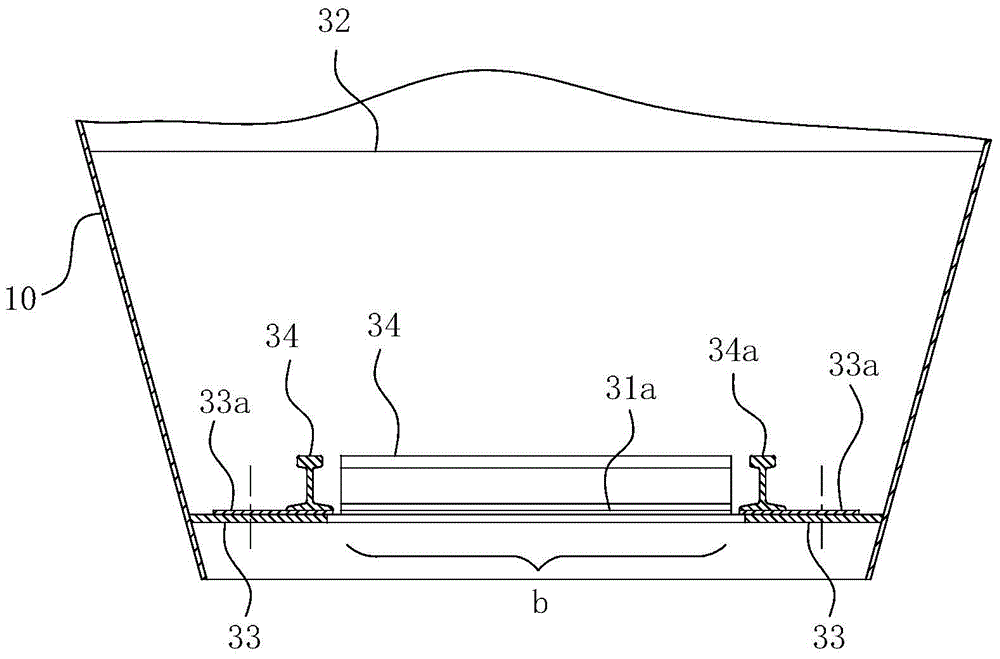

[0029] combine here Figure 1-3 The specific implementation structure and work flow of the present invention are described as follows:

[0030] The specific structure of the present invention is as Figure 1-3 As shown, a funnel 10 and a diversion baffle 20 disposed in the funnel 10 are included. Two installation grooves are welded and fixed at two opposite inner side walls of the funnel 10 . The diversion baffle 20 is in the shape of a long groove, and the bottom of the groove is fixedly connected with a hinged shaft. layout. The mounting groove is provided with a plurality of notches which form snap fit with the hinge shaft, and the notches are all opened upwards. After the deflector baffle 20 is engaged and suspended at the installation groove by the hinge shaft at its top, the hanging position of the deflector baffle 20 can be adjusted by replacing the engaged installation groove to adjust the falling point of the material.

[0031] For ease of understanding, here, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com