Robot

A robot and machine base technology, applied in the field of robots, can solve problems such as inability to adapt to multi-directional, multi-angle compound actions, and single action of robots, and achieve the effects of improving construction efficiency and quality, reducing construction costs, and uniform ash distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

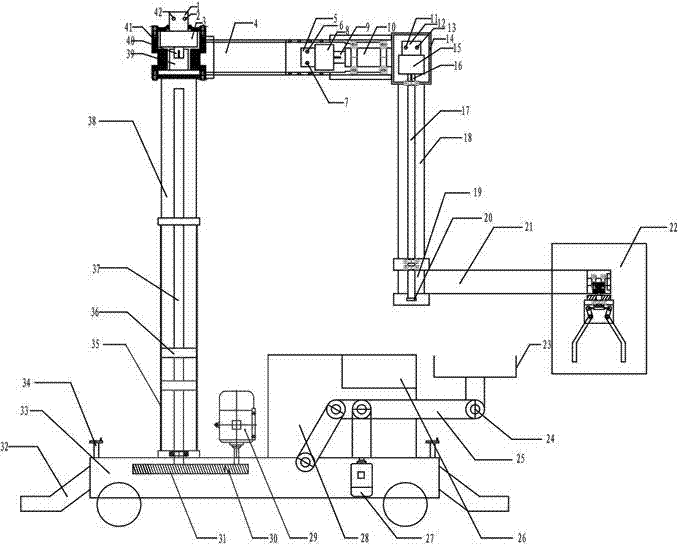

[0017] Such as figure 1 As shown, the embodiment of the present invention includes a frame 33 on which four casters are installed. In order to adjust the levelness between the machine and the ground, there are support legs 32 at the four corners of the bottom of the machine base 33, and the height of the support legs 32 is adjusted through the adjustment rod 34, and the flatness of the machine is determined by observing the automatic leveling compensator installed at the bottom of the machine .

[0018] A vertical rod sleeve 35 is installed on the machine base 33 and a hollow vertical rod 38 whose upper end protrudes from the vertical rod sleeve 35 is installed in the vertical rod sleeve 35 . A screw rod 37 is installed in the hollow vertical rod 38 , and a screw nut 36 mounted on the screw rod 37 is fixedly connected with the hollow vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com