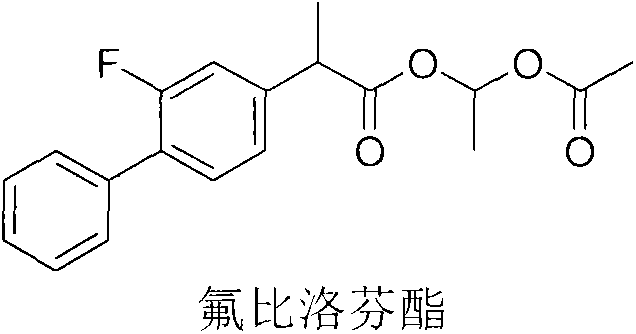

Flurbiprofen axetil fat emulsion injection

A technology of flurbiprofen axetil and fat emulsion, applied in the fields of emulsion delivery, making medicines into special physical or taking forms, organic active ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

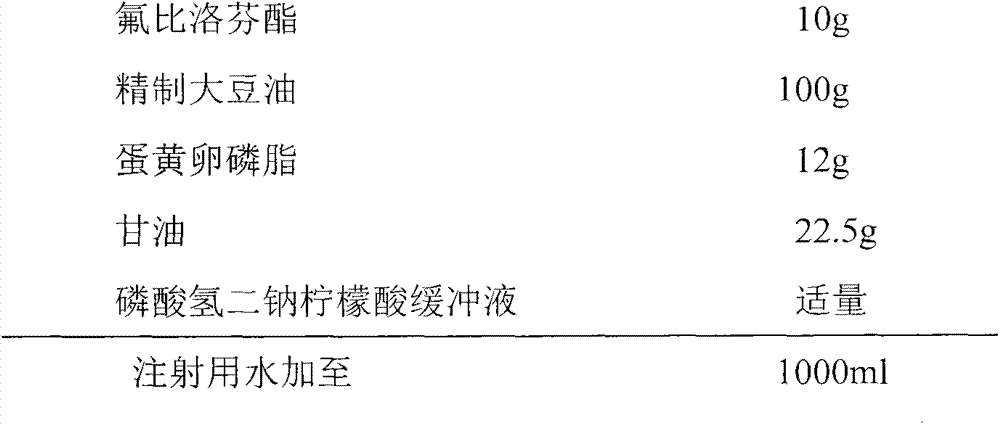

Embodiment 1

[0036] prescription:

[0037]

[0038] Process:

[0039] (1) Preparation of water phase: add glycerin to water to dissolve, heat to 70°C, and set aside;

[0040] (2) Preparation of oil phase: Refined soybean oil is heated to 70°C, egg yolk lecithin (80% phosphatidylcholine content, 17% phosphatidylethanolamine content) is added to dissolve respectively, and flurbiprofen axetil is added, stirred to make its dissolution;

[0041] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 70°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum;

[0042] (4) pH value adjustment: quickly cool down the colostrum in step (3) below 30°C, and adjust the pH value to 4.5-6.5 with disodium hydrogen phosphate citric acid buffer solution (the molar ratio of disodium hydrogen phosphate to citric acid is 4:1) ;

[0043] (5) High-pressure homogenization: the colostrum in step (4) is ho...

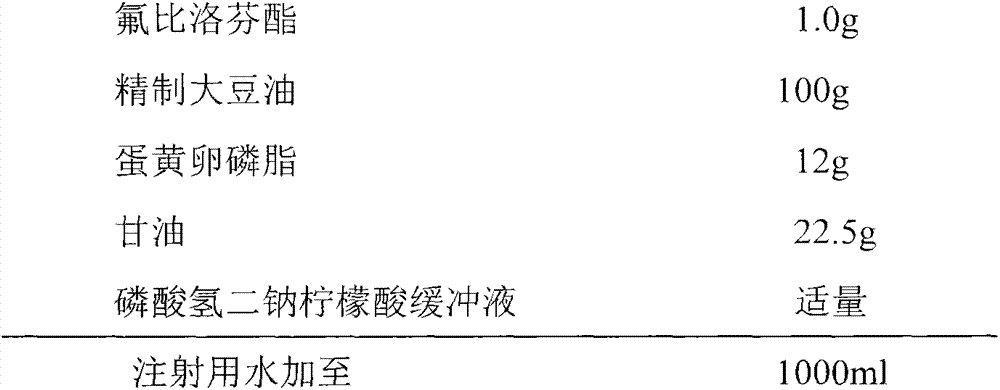

Embodiment 2

[0047] prescription:

[0048]

[0049] Process:

[0050] (1) Preparation of water phase: add glycerin to water to dissolve, heat to 70°C, and set aside;

[0051] (2) Preparation of oil phase: Refined soybean oil is heated to 70°C, egg yolk lecithin (80% phosphatidylcholine content, 17% phosphatidylethanolamine content) is added to dissolve respectively, and flurbiprofen axetil is added, stirred to make its dissolution;

[0052] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 70°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum;

[0053] (4) pH value adjustment: quickly cool down the colostrum in step (3) below 30°C, and adjust the pH value to 4.5-6.5 with disodium hydrogen phosphate citric acid buffer solution (the molar ratio of disodium hydrogen phosphate to citric acid is 4:1) ;

[0054] (5) High-pressure homogenization: the colostrum in step (4) is ho...

Embodiment 3

[0058] prescription:

[0059]

[0060]

[0061] Process:

[0062] (1) Preparation of water phase: add glycerin to water to dissolve, heat to 70°C, and set aside;

[0063] (2) Preparation of oil phase: Heat soybean oil, olive oil and medium-chain triglycerides to 70°C, add egg yolk lecithin (80% phosphatidylcholine content, 17% phosphatidylethanolamine content) to dissolve, add fluorine Biprofen axetil drug, stir to dissolve;

[0064] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 70°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum;

[0065] (4) pH value adjustment: quickly cool down the colostrum in step (3) below 30°C, and adjust the pH value to 4.5-6.5 with disodium hydrogen phosphate citric acid buffer solution (the molar ratio of disodium hydrogen phosphate to citric acid is 4:1) ;

[0066] (5) High-pressure homogenization: the colostrum in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com