Zero-pressure drip irrigation system

A dripper and head cover technology, which is applied in the direction of climate change adaptation, horticulture, botany equipment and methods, etc., can solve the problems of high cost of drip irrigation system, high operating cost, easy blockage of drippers, etc., to reduce equipment purchase costs and The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

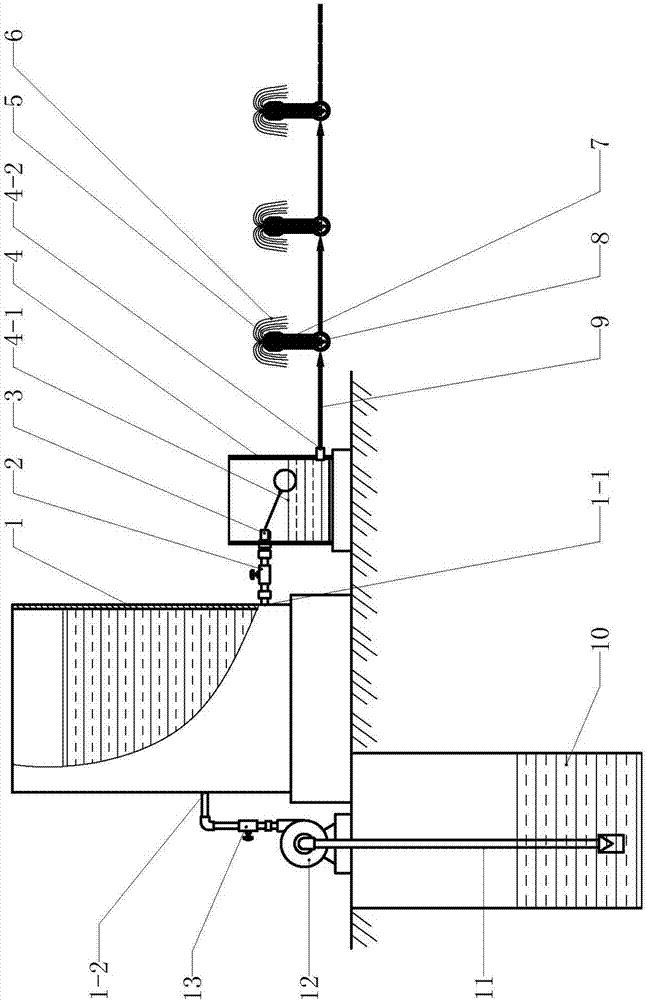

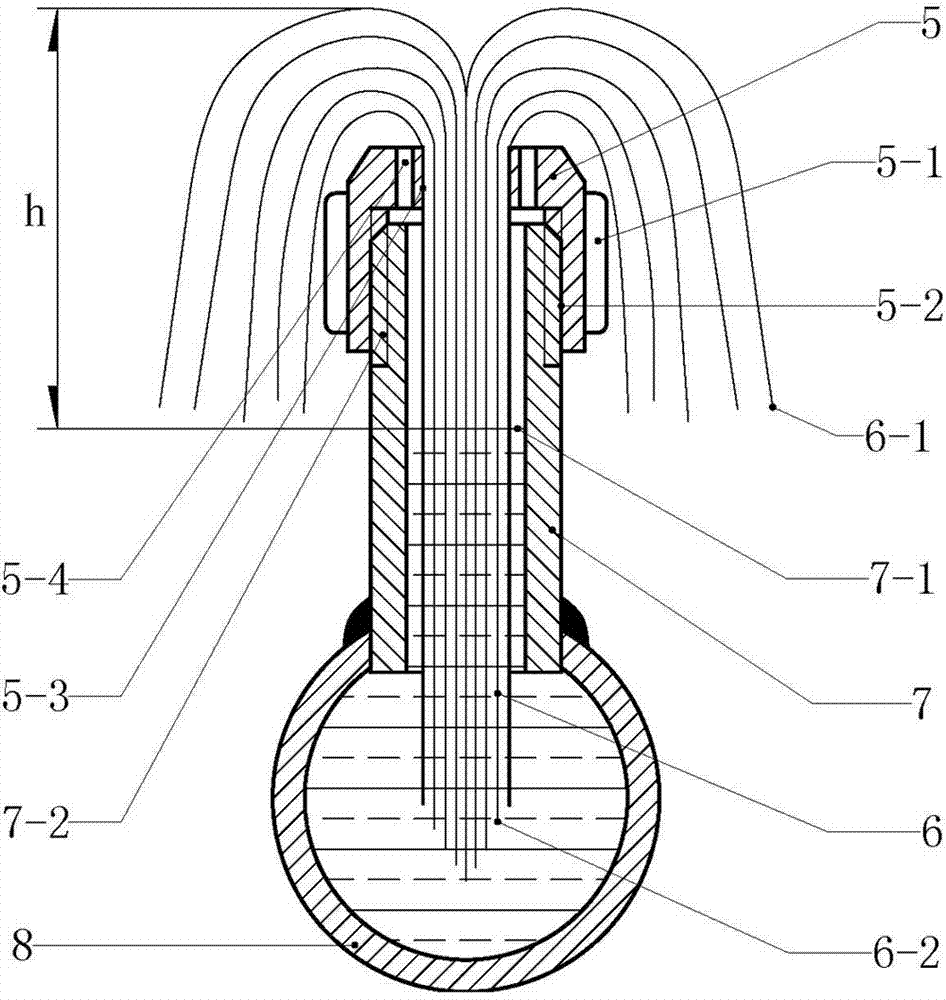

[0014] Example figure 1 and figure 2 In the embodiment shown, a pressureless drip irrigation system is composed of a water storage tank (1), a balance water tank (4), a water supply pipe (9), a water diversion branch pipe (8), a water diversion capillary (7) and a capillary dripper, wherein , the water supply pipe (9) and the water diversion branch pipe (8) each have a branch interface; the upper end of the water diversion capillary (7) has a connecting thread (7-2); the capillary dripper consists of a dripper cover (5) and a capillary bundle (6 ), the dripper cover (5) is a revolving structure, there is an air vent (5-4) on the top of the dripper cover (5), and there is a bayonet (5-3) in the center of the revolving body of the dripper cover (5). ), the capillary bundle (6) is installed in the bayonet (5-3) of the dripper cover (5), there is a mounting screw (5-2) inside the wall of the dripper cover (5), and the dripper cover (5) (5) There is a hand-twisting ear flap (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com