45-degree wing butt G-sectional material for switch cabinet

A technology of switch cabinets and wing angles, which is applied to substation/switch layout details, electrical components, substation/distribution device shells, etc. It can solve the problems of reduced processing cycle and production efficiency, increased welding process, and increased material cost, etc., to achieve The effect of increasing mechanical strength and protective performance, reducing external dependence, and improving surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

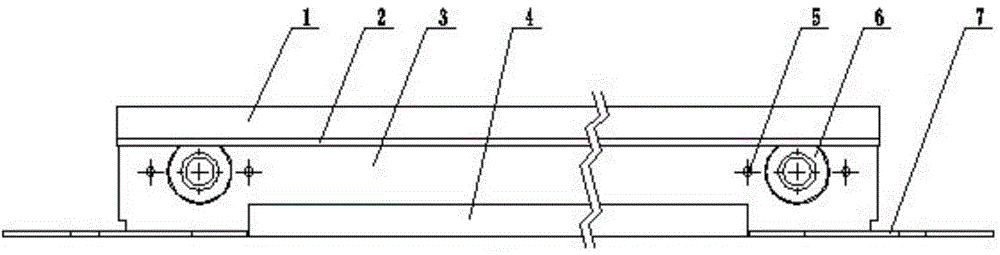

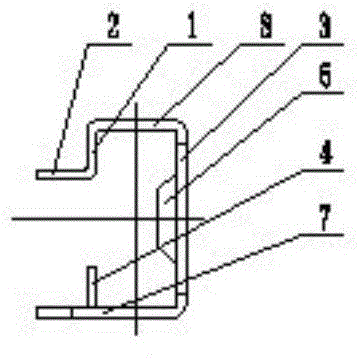

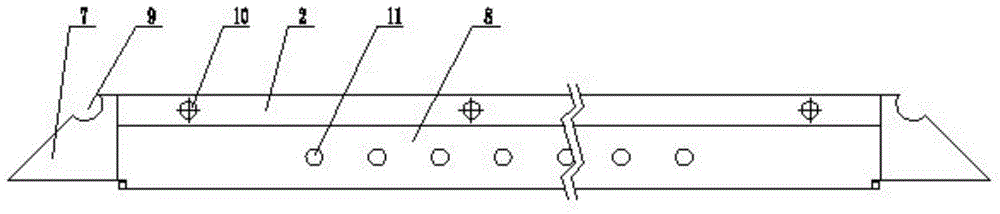

[0021] A 45-degree wing angle G profile for switchgear, which is integrally made of front flange 2, upper vertical edge 1, upper plate 8, rear vertical plate 3, lower plate 7 and lower vertical edge 4, and its cross-section is 40mm×40mm , the upper plate, the rear vertical plate and the lower plate are folded at right angles to the frame profile of the front opening, and the functional module holes 11 are evenly distributed in the middle of the upper plate; The lower part of the edge is folded forward at right angles to form a front flanging, and base plate installation holes 10 are evenly distributed on the front flanging; Two positioning holes 5 are coaxially and symmetrically made respectively; both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com