A Scanning Tunneling Microscope Needle Corrosion Instrument

A scanning tunneling and microscope technology, applied in the field of scanning tunneling microscope needle tip making devices, can solve the problems of reducing the success rate of needle tip making, unstable experimental results, and increasing the difficulty of experimental control, achieving easy control and analysis, improved speed, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

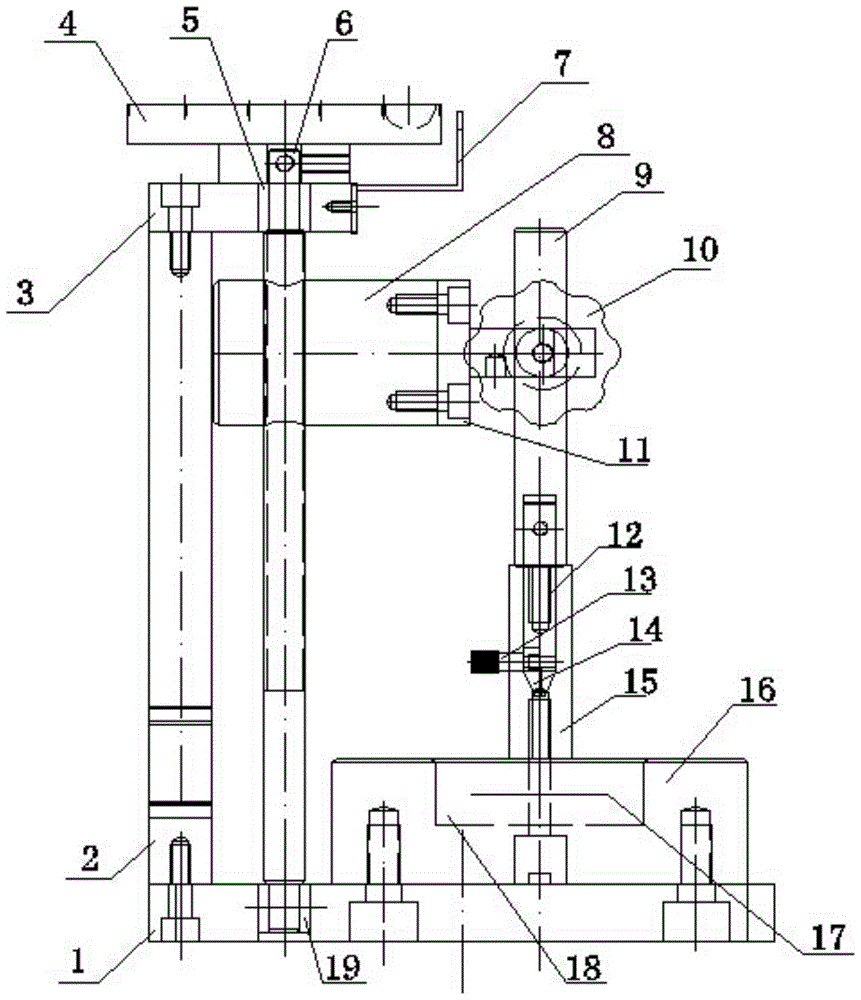

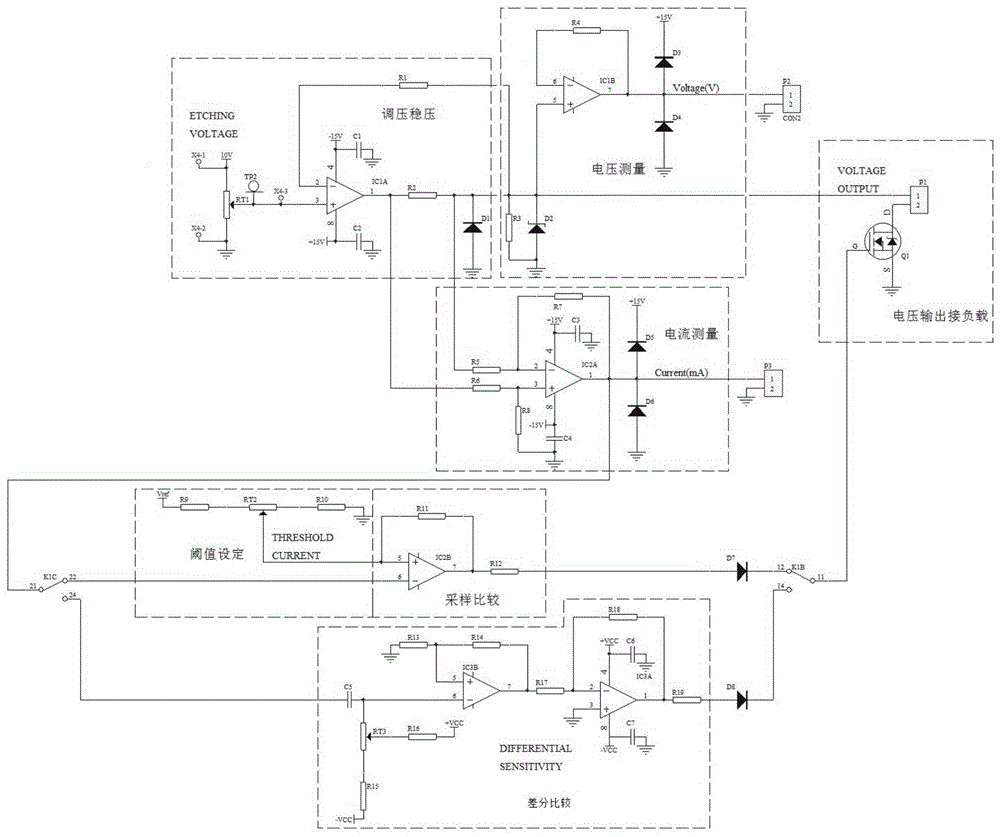

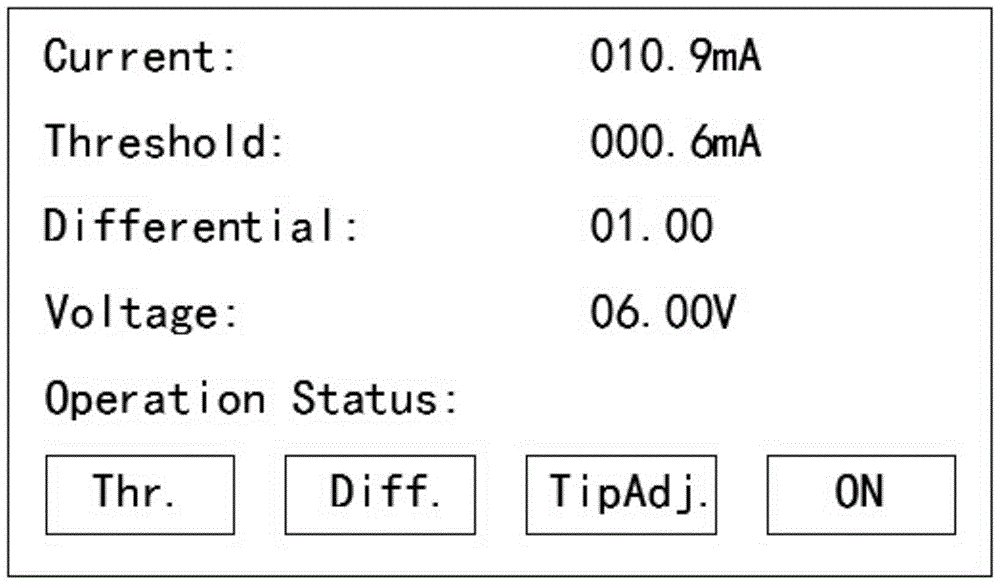

[0032] Such as Figure 1-3 As shown, a scanning tunneling microscope needle-point corrosion instrument, including mechanical components, working circuit and control power supply.

[0033] The mechanical assembly includes base 1, bracket 2, upper cover 3, top cover knob 4, copper sleeve A5, threaded rod 6, pointer 7, lifting and fixing block 8, anode electrode rod 9, fixing knob 10, electrode fixing end 11 , Three-jaw fixture A12, knob 13, three-jaw fixture B14, negative electrode rod 15, disc 16, electrode ring 17, beaker 18 and copper sleeve B19.

[0034] Described base 1 adopts screw connection and fixation with bracket 2, disk 16 respectively, plays the overa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com