Flexoelectric passive torque sensor

A technology of torque sensor and flexoelectric coefficient, applied in the field of torque sensor, to achieve the effect of reducing the demand for power supply and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

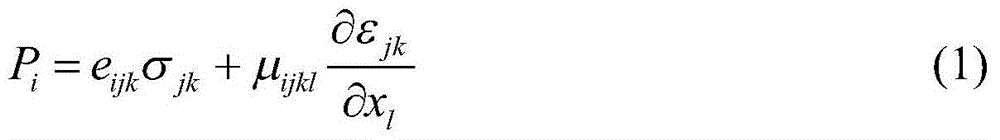

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

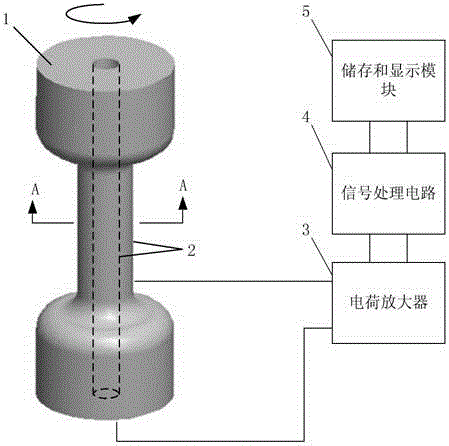

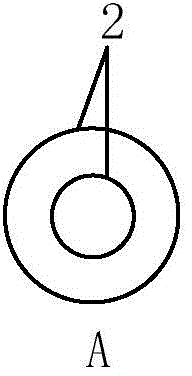

[0032] Such as figure 1 and figure 2 As shown, the flexoelectric passive torque sensor of the present invention includes a sensing unit 1 with a large flexoelectric coefficient with a clamping end and a concentric through hole, attached to the inner wall of the through hole of the sensing unit 1 and the sensing unit An external electrode 2, a charge amplifier 3 electrically connected to the electrode 2, a signal processing circuit 4 electrically connected to the charge amplifier 3, and a storage display module 5 electrically connected to the signal processing circuit 4.

[0033] As a preferred embodiment of the present invention, the flexoelectric coefficient of the sensing unit 1 is greater than 10 -10 C / m order of magnitude.

[0034] As a preferred embodiment of the present invention, the sensing unit 1 adopts a material with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com