Nonmetallic flexible composite continuous pipe oil extraction device

An oil production device, non-metallic technology, applied in the field of non-metallic flexible composite coiled tubing oil production devices, can solve the problems of heavy construction work, high labor intensity, and easy corrosion of metal pipes, and achieve low operating cost, high operating efficiency, and reduced The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

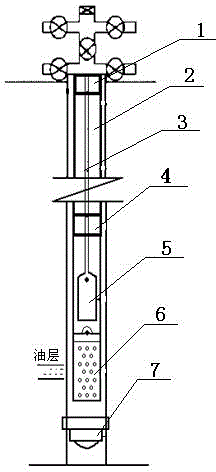

[0029] In order to overcome the problems that the metal pipes in the existing oil production equipment are easy to corrode and need to be connected by a single piece, the construction workload is large and the labor intensity is high, this embodiment provides a method such as figure 1 The shown non-metallic flexible composite coiled tubing oil production device includes a wellhead hanger 1, and a conversion joint 4, an oil well pump 5, a screen pipe 6 and a plug 7 connected sequentially from top to bottom, and the oil well pump 5 passes through the oil well The rod 3 is connected to the wellhead hanger 1 , and the non-metallic composite pipe 2 is connected between the mouth hanger 1 and the conversion joint 4 , and the sucker rod 3 passes through the non-metallic composite pipe 2 .

[0030] The wellhead hanger 1 and the non-metallic composite pipe 2 are processed and connected by vulcanization, and the wellhead hanger 1 and the non-metallic composite pipe 2 are vulcanized and b...

Embodiment 2

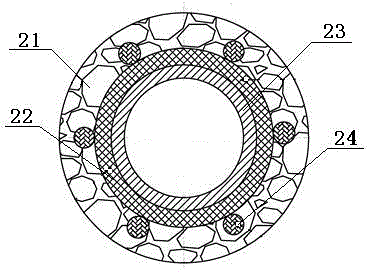

[0034] On the basis of Example 1, the non-metal composite pipe 2 is composed of a protective layer 21, a reinforcing layer 22, a tensile layer 23, and a steel wire rope 24; the protective layer 21, the reinforcing layer 22 and the tensile layer 23 are formed from the outside to The steel wire ropes 24 are distributed around the outside of the reinforcing layer 22.

[0035] Wherein, the protective layer 21 is made of rubber, which is extruded and coated on the outside of the reinforcement layer 22, and is the outermost layer of shield of the non-metallic composite pipe 2, which comprehensively protects all components inside the pipe, and has good wear resistance and corrosion resistance.

[0036] The reinforcing layer 22 is made of glass fiber, and the reinforcing layer 22 is a multi-strand braided wire mesh structure, which has high tensile strength and tear resistance, can greatly improve the internal pressure resistance of the pipe wall, and the compressive strength can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com