Medium-and-low speed magnetic levitation railway low route continuous framework type bearing rail beam structure and construction method

A technology of low-lying lines and frame beams, which is applied to the continuous frame-type rail-beam structure of low-speed magnetic levitation low-lying lines and its construction field, which can solve the problems of difficulty in making integral formwork and many construction procedures, and achieve convenient and simplified construction control The construction process and the effect of reducing the difficulty of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

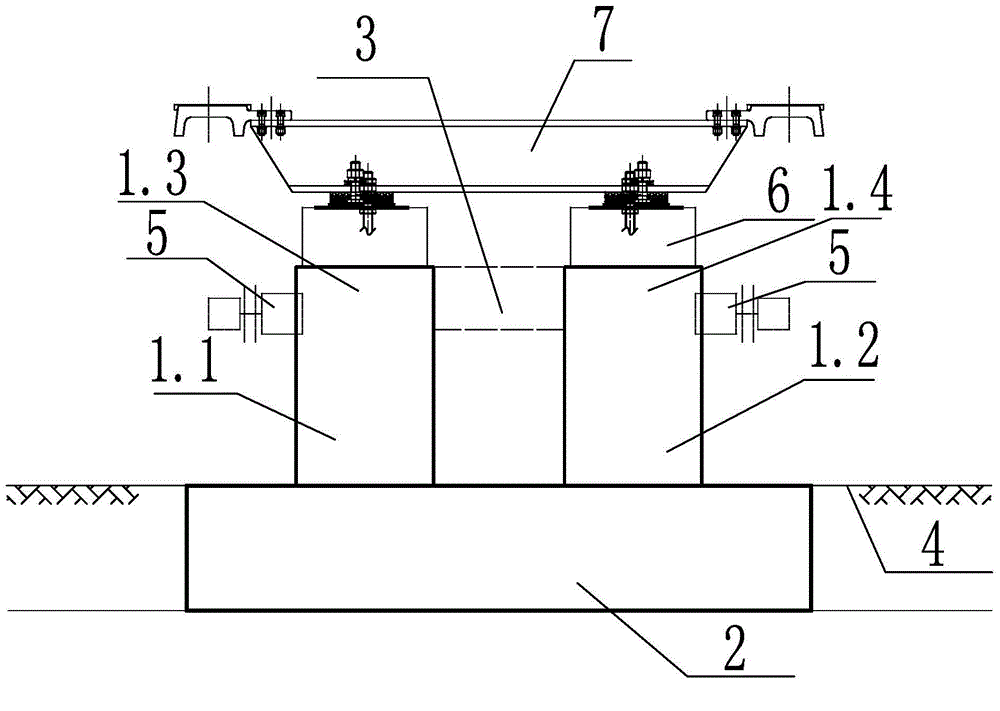

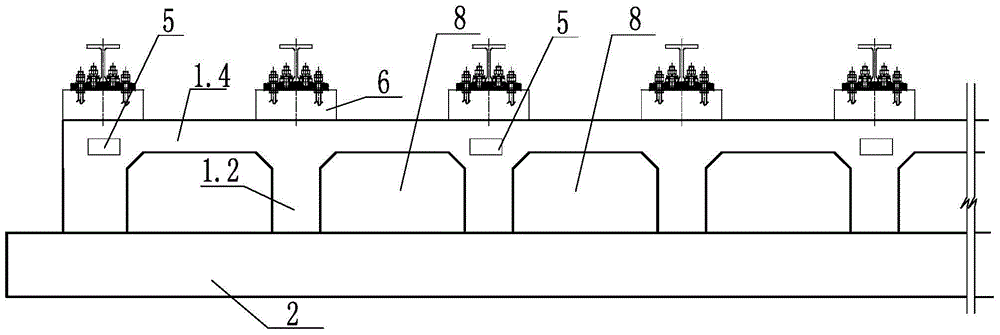

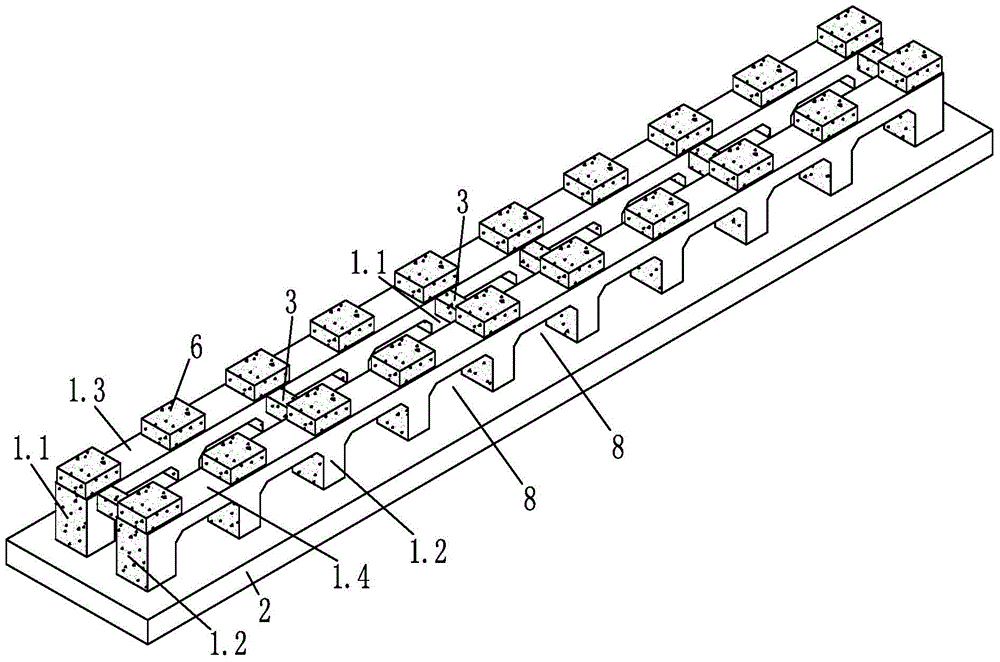

[0033] like Figure 1~3 The continuous frame-type rail-bearing beam structure of the medium and low-speed magnetic levitation low-set line shown includes a reinforced concrete bottom plate 2, a rail row 7, and multiple rows of sleeper pedestals 6 arranged along the line direction, and it also includes a left top plate 1.3 of the reinforced concrete continuous frame beam. , the right top plate 1.4 of the reinforced concrete continuous frame beam, a plurality of reinforced concrete continuous frame beams arranged at equal intervals along the direction of the line on the reinforced concrete bottom plate 2, the left frame column 1.1, and a plurality of left frame columns 1.1 arranged at equal intervals along the direction of the line on the reinforced concrete bottom plate 2 The right frame column 1.2 of the reinforced concrete continuous frame beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com