Sewing machine capable of positioning seam allowance, seam allowance positioning mechanism and method

A technology of positioning mechanism and sewing machine, applied in the field of sewing machine for positioning mechanism of seam allowance and positioning seam allowance, can solve the problems that the width of seam allowance cannot be accurately estimated, the appearance quality of finished garments is affected, the width of seam allowance is inconsistent, etc. Consistent seam width and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

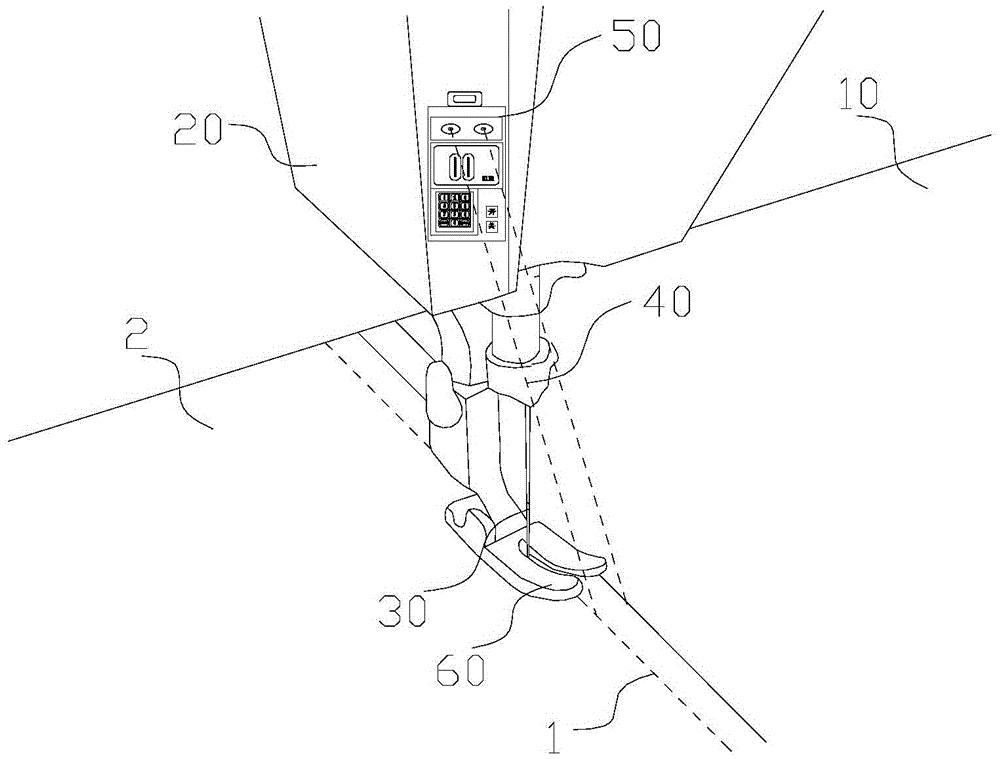

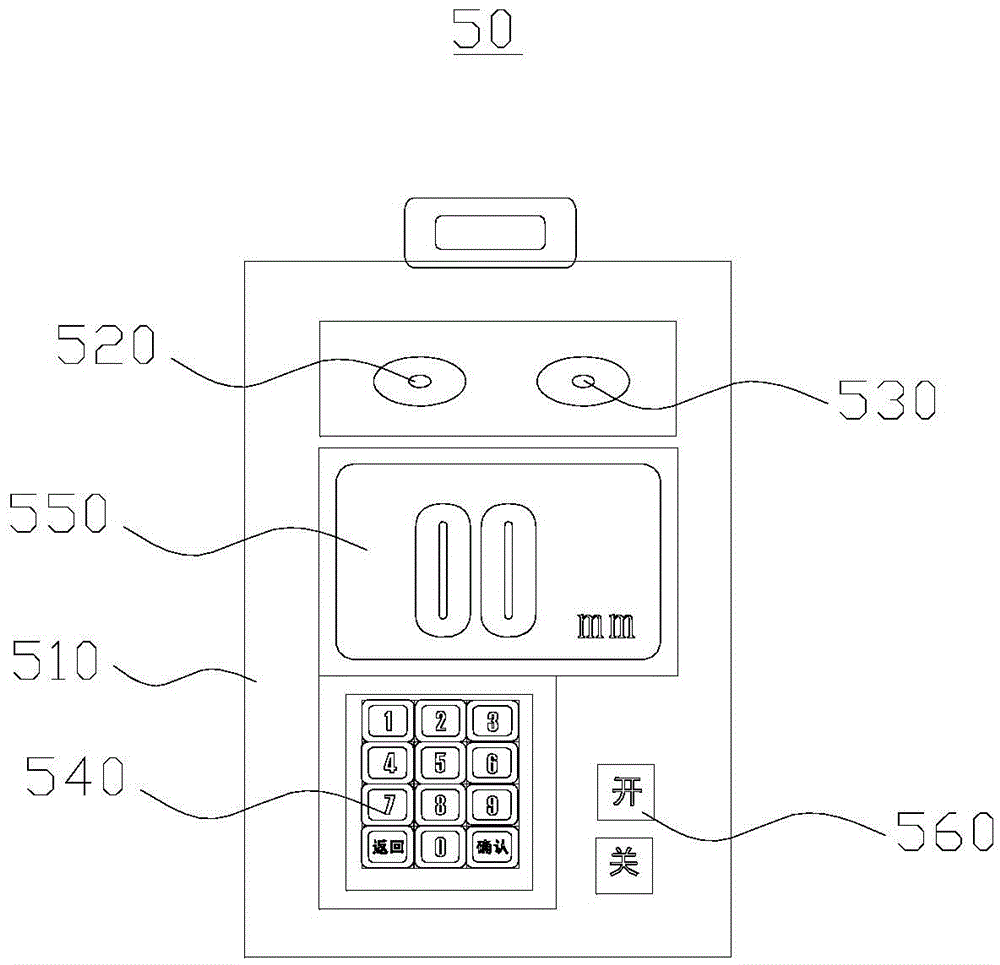

[0027] Such as figure 1 , figure 2 As shown, a sewing machine capable of positioning seam allowances includes a machine body 10 and a machine head 20 arranged on the machine body 10. The machine head 20 is provided with a needle bar 40 for installing machine needles 30, and also includes a machine head arranged on the machine head. The seam positioning mechanism 50 on 20, the seam positioning mechanism 50 includes a positioning body 510, a controller, a first laser emitter 520, a second laser emitter 530, a driving member, a laser measuring sensor, and a width input member 540, The controller is electrically connected to the first laser emitter 520, the second laser emitter 530, the drive element, the laser measurement sensor and the width input element 540 respectively, the first laser emitter 520 is installed on the positioning body 510, The second laser emitter 530 is connected with the driving member, and the second laser emitter 530 is movably arranged on one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com