Preparation method of flavor-enhancing and moisturizing agent for burley tobacco for tobacco

A technology for burley tobacco and moisturizing agent, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as the decline of physical properties of shredded tobacco, and achieve rich aroma of cigarettes, rich tobacco aroma, and irritation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

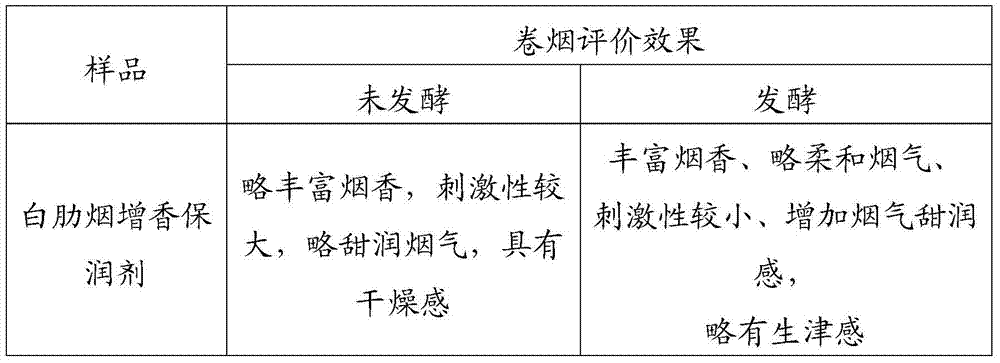

Embodiment 1

[0021] A preparation method of a burley tobacco flavoring moisturizer, comprising the following steps:

[0022] 1) Preparation of Burley tobacco extract: Weigh Burley tobacco and add it to water. According to the material weight ratio of Burley tobacco and extraction solvent: 1:6, ultrasonically extract at 60°C for 4 hours, and the obtained extract Filter after standing to cool, the obtained filtrate is Burley tobacco extract;

[0023] 2) Fermentation of mixed bacteria: using Burley tobacco extract as a substrate, adding ethanol, using mixed bacteria in a closed state, fermenting for 5 days at a pH value of 4.0 and a fermentation temperature of 25°C to obtain a fermented product. Among them, the volume ratio of Burley tobacco extract to ethanol is: 100:5, and the mixed bacteria is formed by mixing active dry acetic acid bacteria and rhizopus in a weight ratio of 1:1;

[0024] 3) Post-treatment of the fermented product: add 3 times the volume of 95% alcohol solution to the fer...

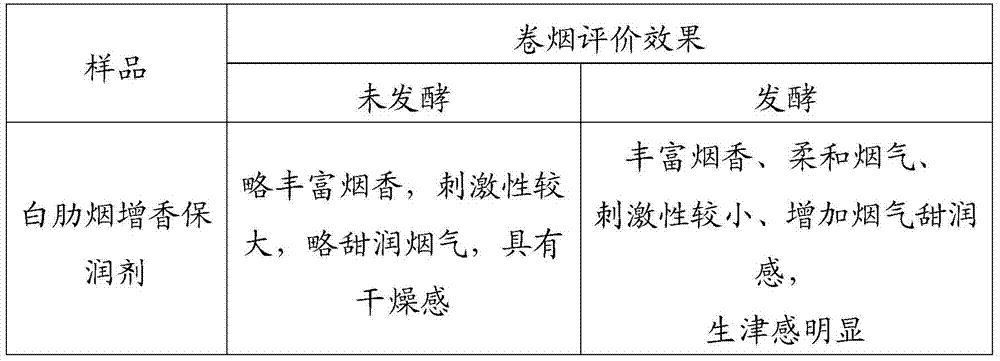

Embodiment 2

[0033] A preparation method of a burley tobacco flavoring moisturizer, comprising the following steps:

[0034] 1) Preparation of Burley tobacco extract: Weigh Burley tobacco and add it to water. According to the material weight ratio of Burley tobacco and extraction solvent: 1:8, ultrasonically extract at 65°C for 2 hours, and the obtained extract Filter after standing to cool, the obtained filtrate is Burley tobacco extract;

[0035] 2) Fermentation of mixed bacteria: take Burley tobacco extract as substrate, add ethanol, use mixed bacteria in a closed state, and ferment for 8 days at a pH value of 6.0 and a fermentation temperature of 20°C to obtain a fermented product. Among them, the volume ratio of burley tobacco extract to ethanol is: 100:8, and the mixed bacteria is formed by mixing active dry acetic acid bacteria and rhizopus in a weight ratio of 1:1;

[0036] 3) Post-treatment of the fermented product: add 5 times the volume of 75% alcohol solution to the fermented ...

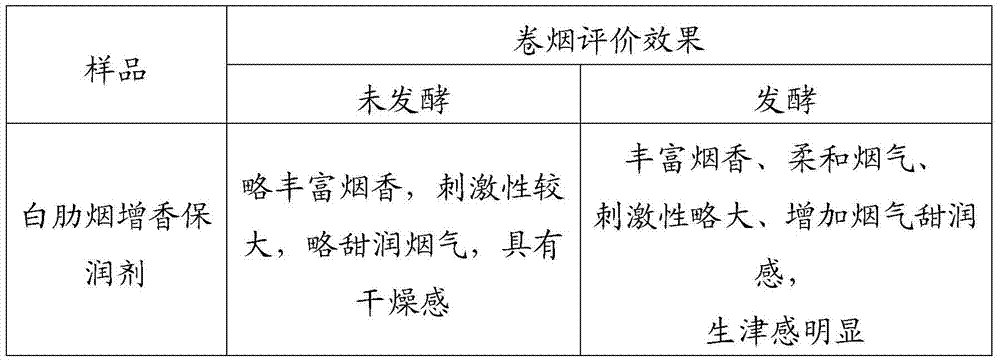

Embodiment 3

[0045] A preparation method of a burley tobacco flavoring moisturizer, comprising the following steps:

[0046] 1) Preparation of Burley tobacco extract: Weigh Burley tobacco and add it to water. According to the material weight ratio of Burley tobacco and extraction solvent: 1:10, conduct ultrasonic extraction at 55°C for 6 hours, and extract the obtained extract Filter after standing to cool, the obtained filtrate is Burley tobacco extract;

[0047] 2) Fermentation of mixed bacteria: using Burley tobacco extract as a substrate, adding ethanol, using mixed bacteria in a closed state, fermenting for 3 days at a pH value of 7.0 and a fermentation temperature of 40°C to obtain a fermented product. Among them, the volume ratio of Burley tobacco extract to ethanol is: 100:6, and the mixed bacteria is formed by mixing active dry acetic acid bacteria and rhizopus in a weight ratio of 1:1;

[0048] 3) Post-treatment of the fermented product: add 2 times the volume of 90% alcohol sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com