Silicon carbide smelting method

A smelting method and silicon carbide technology, applied in the field of smelting, can solve the problems of unstable furnace production, high energy consumption, mixed crystal forms, etc., and achieve the effects of improving production efficiency, reducing energy consumption, and preventing secondary decomposition at high temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

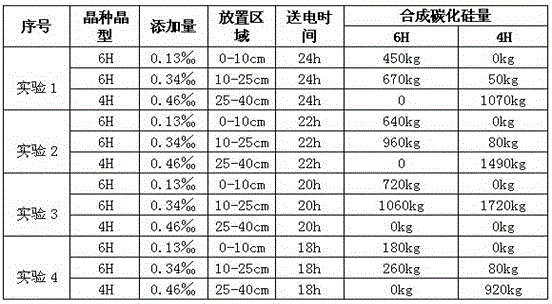

Embodiment 1

[0016] Embodiment 1, a kind of silicon carbide smelting method, its steps are as follows:

[0017] (1) SiC seed crystal treatment: choose silicon carbide of different crystal forms as the seed crystal according to the different crystal forms of silicon carbide, and perform the following treatment on the silicon carbide that will be used as the seed crystal: first crush and sieve the silicon carbide , select silicon carbide with a particle size of 3 mm for purification, use pickling method for purification, then rinse with pure water until the pH value is 6.5, and dry;

[0018] (2) Addition of silicon carbide seed crystals: the addition position and amount of silicon carbide seed crystals are as follows: with the graphite electrode as the center, 6H silicon carbide seed crystals are placed within 0~10cm, and the added seed crystals account for 10% of the mass percentage of the mixture. 0.1%, place 6H silicon carbide seeds within the range of 10cm~25cm, the added seeds account f...

Embodiment 2

[0019] Embodiment 2 A kind of silicon carbide smelting method, its steps are as follows:

[0020] (1) SiC seed crystal treatment: choose silicon carbide of different crystal forms as the seed crystal according to the different crystal forms of silicon carbide, and perform the following treatment on the silicon carbide that will be used as the seed crystal: first crush and sieve the silicon carbide , select silicon carbide with a particle size of 8 mm for purification, use pickling method for purification, then rinse with pure water until the pH value is 7.5, and dry;

[0021] (2) Addition of silicon carbide seed crystals: the addition position and amount of silicon carbide seed crystals are as follows: with the graphite electrode as the center, 6H silicon carbide seed crystals are placed within 0~10cm, and the added seed crystals account for 10% of the mass percentage of the mixture. 5%, place 6H silicon carbide seeds within the range of 10cm~25cm, the added seeds account for ...

Embodiment 3

[0022] Embodiment 3 A kind of silicon carbide smelting method, its steps are as follows:

[0023] (1) SiC seed crystal treatment: choose silicon carbide of different crystal forms as the seed crystal according to the different crystal forms of silicon carbide, and perform the following treatment on the silicon carbide that will be used as the seed crystal: first crush and sieve the silicon carbide , select silicon carbide with a particle size of 5 meters for purification, use pickling method for purification, then rinse with pure water until the pH value is 7.0, and dry;

[0024] (2) Addition of silicon carbide seed crystals: the addition position and amount of silicon carbide seed crystals are as follows: with the graphite electrode as the center, 6H silicon carbide seed crystals are placed within 0~10cm, and the added seed crystals account for 10% of the mass percentage of the mixture. 1%, place 6H silicon carbide seeds within the range of 10cm~25cm, the added seeds account ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com