Stacking device for aluminum sheet transferring

A technology of conveying device and aluminum sheet, applied in the field of aluminum sheet processing, can solve the problems of low efficiency and high equipment cost, and achieve the effects of improving efficiency, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

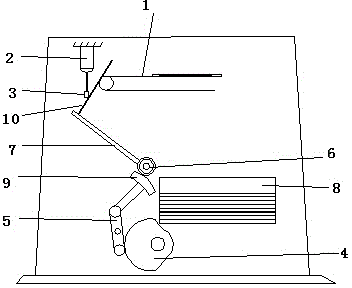

[0012] The reference signs in the description of the drawings are: conveyor belt 1, cylinder 2, pusher block 3, cam mechanism 4, linkage rod 5, transmission shaft 6, rotating plate 7, stacking box 8, arc-shaped tooth plate 9, aluminum sheet 10.

[0013] like figure 1 As shown, the technical solution provides a stacking device for conveying aluminum sheets, including a frame, a conveying device and a stacking device. The conveying device includes a conveyor belt 1 and a pressing device, the pressing device is installed above the output port of the conveyor belt 1, the pressing device includes a cylinder 2 and a pushing block 3, and the pushing block 3 is fixedly installed on the piston rod of the cylinder 2. In order to avoid damage to the aluminum sheet 10 caused by the pressing device when pushing the aluminum sheet 10, a rubber layer is provided on the pushing block 3, and the rubber is soft, so that there is enough buffer time when it contacts the aluminum sheet 10.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com