Front vertical beam reinforcing plate, right front vertical beam and automobile

A technology for reinforcing plates and front longitudinal beams, applied to vehicle parts, substructure, transportation and packaging, etc., can solve problems such as unsatisfactory ductility of reinforcing plates, excessive structural design performance, and inability to carry collision energy, etc., to achieve easy renewal and improvement , Reduce the risk of bearing deformation, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

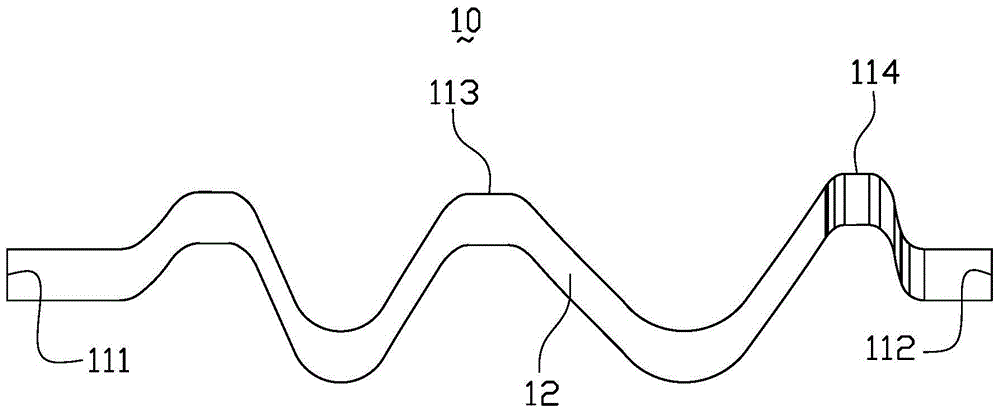

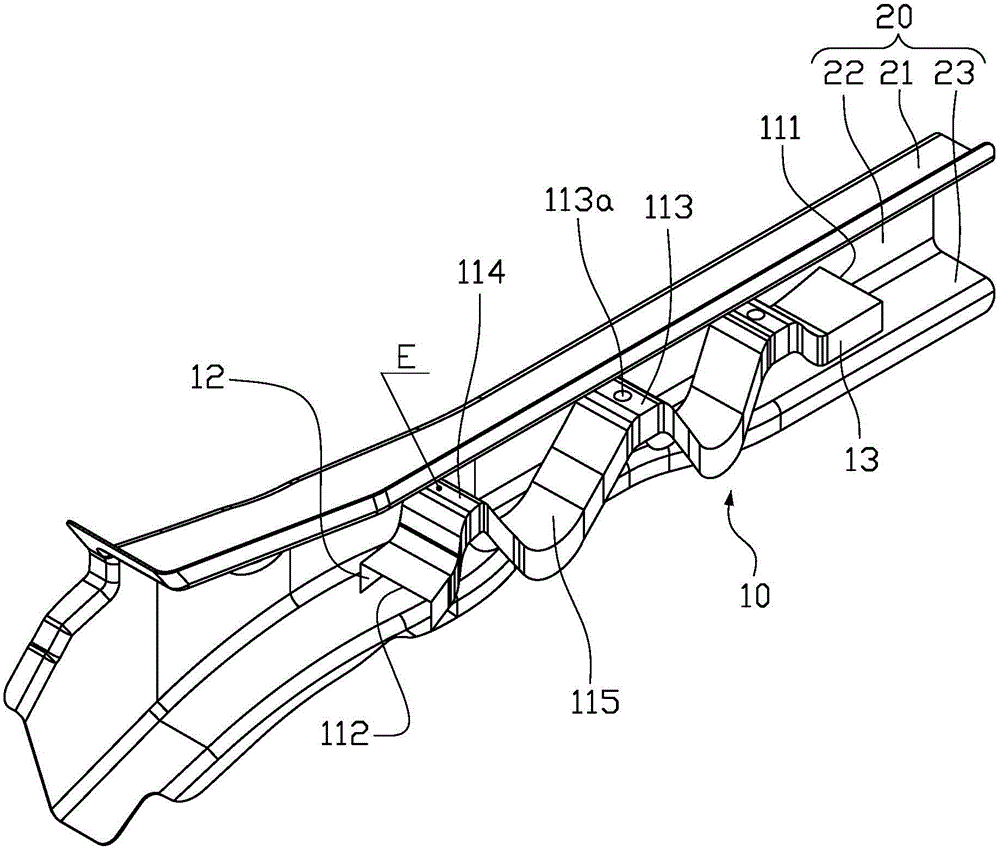

[0022] figure 1 It is a structural schematic diagram of the front longitudinal beam reinforcement plate in the embodiment of the present invention. figure 2 It is a schematic front view of the front longitudinal beam reinforcement plate in the embodiment of the present invention. Please combine figure 1 and figure 2 , the automobile front side beam reinforcement plate 10 of the present invention comprises a reinforcement plate body 11 and a first connection edge 12 and a second connection edge 13 located on both sides of the reinforcement plate body 11, and the reinforcement plate body 11 has a front end of a corresponding longitudinal beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com