A polyurethane foam machine

A foaming machine, polyurethane technology, applied in mixers, mixers with rotating stirring devices, dissolving, etc., can solve the problems of difficulty in producing high-quality finished products, unstable polyurethane foaming process, and molding accuracy of polyurethane foaming materials Poor and other problems, to achieve the effect of simple structure, uniform and moderate bubble size, and stable foaming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

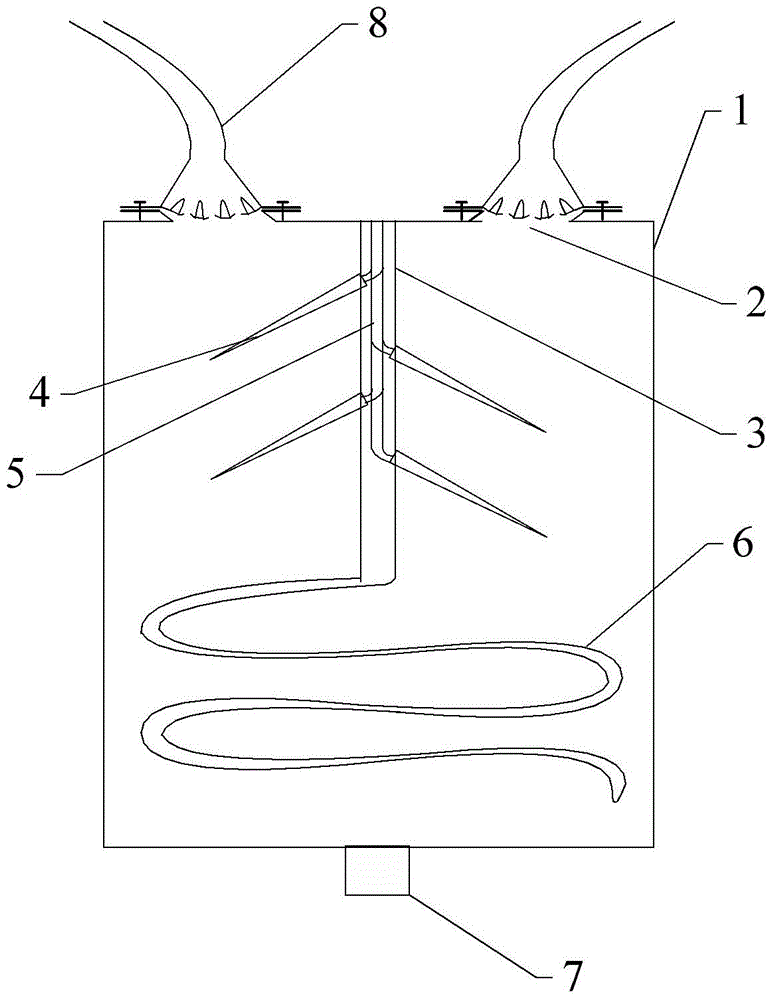

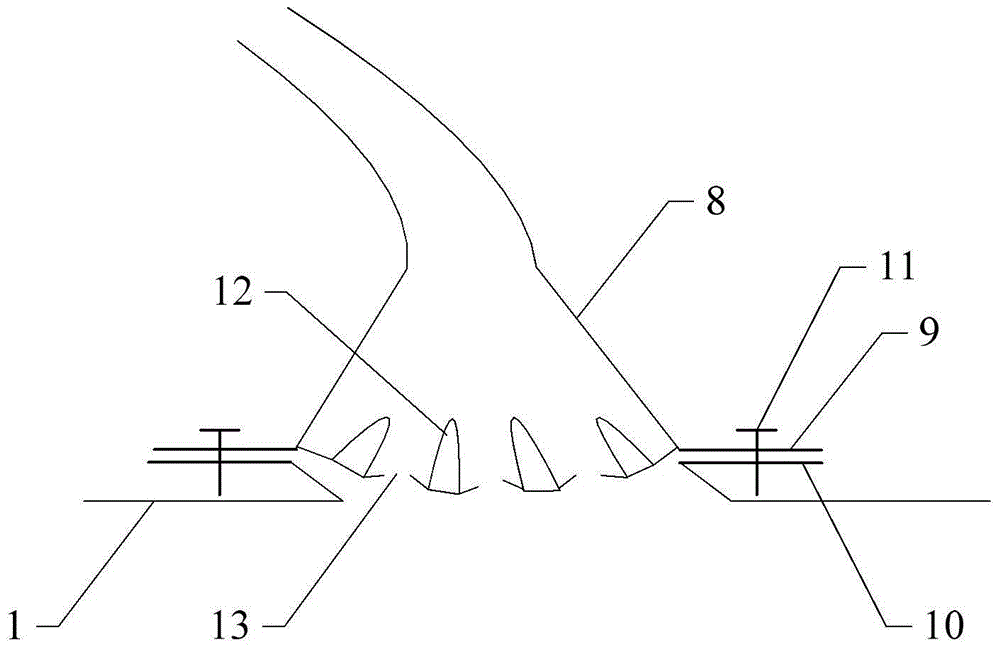

[0040] Such as figure 1 and figure 2 Shown, a kind of polyurethane foaming machine is characterized in that, comprises:

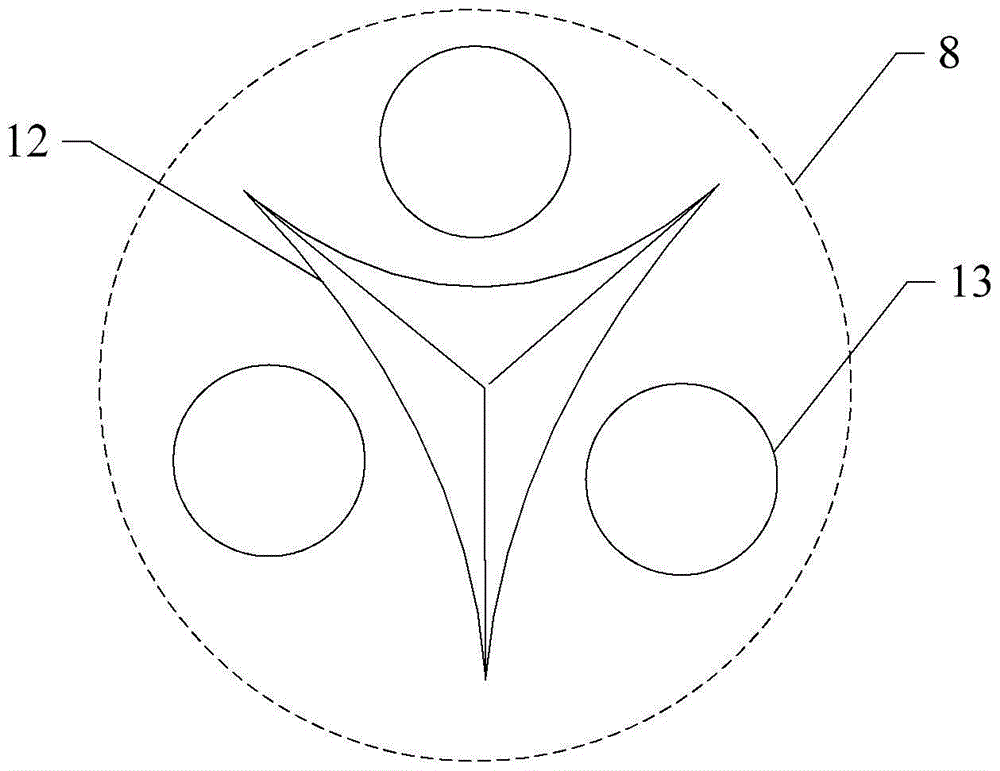

[0041] Feeding device, it is an umbrella-shaped shower head 8; The umbrella-shaped shower head 8 comprises, as image 3 As shown, the cone 12 has its lower end surface fixed on the inner surface of the spray surface of the umbrella-shaped shower head 8, and its tip extends to the opposite direction of the spray surface of the umbrella-shaped shower head 8, and the cross-section of the cone 12 is a side Long triangular shape with radians; spray holes 13, which are evenly distributed on the spray surface around the cone 12.

[0042] In the last scheme, a cone 12 is set in the umbrella-shaped nozzle 8, so that the feed direction flows from the tip of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com