A kind of gel centrifugal molding method of ceramic embryo body

A ceramic embryo body and centrifugal molding technology, which is applied to ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of difficult distribution of ceramic particles, low ceramic density, and plain embryo cracks, etc., to achieve simple molding process, High material utilization, no cracks inside the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific Embodiment 1: This embodiment is a gel centrifugal molding method for ceramic embryos, which is specifically completed according to the following steps:

[0027] 1. Prepare a mixed solution: dissolve the organic monomer and crosslinking agent in deionized water, add a dispersant, and then perform ultrasonic treatment to obtain a mixed solution;

[0028] The mass ratio of the organic monomer described in step 1 to the crosslinking agent is 1:(0.08~0.12);

[0029] The mass ratio of organic monomer and deionized water described in step 1 is 1:(10~100);

[0030] The mass ratio of dispersant described in step 1 and deionized water is 1:(50~1000);

[0031] 2. Preparation of slurry: Add ceramic powder to the mixed solution obtained in step 1, and then ball mill for 8h-24h at a ball-to-material ratio of 3:1 and a ball milling speed of 190r / min-260r / min to obtain a slurry;

[0032] The mass ratio of the ceramic powder described in step 2 to the mixed solution obtained...

specific Embodiment approach 2

[0040] Embodiment 2: The differences between this embodiment and Embodiment 1 are: the power of the ultrasonic treatment in step 1 is 50W-200W, and the ultrasonic time is 5min-20min. Others are the same as the first embodiment.

specific Embodiment approach 3

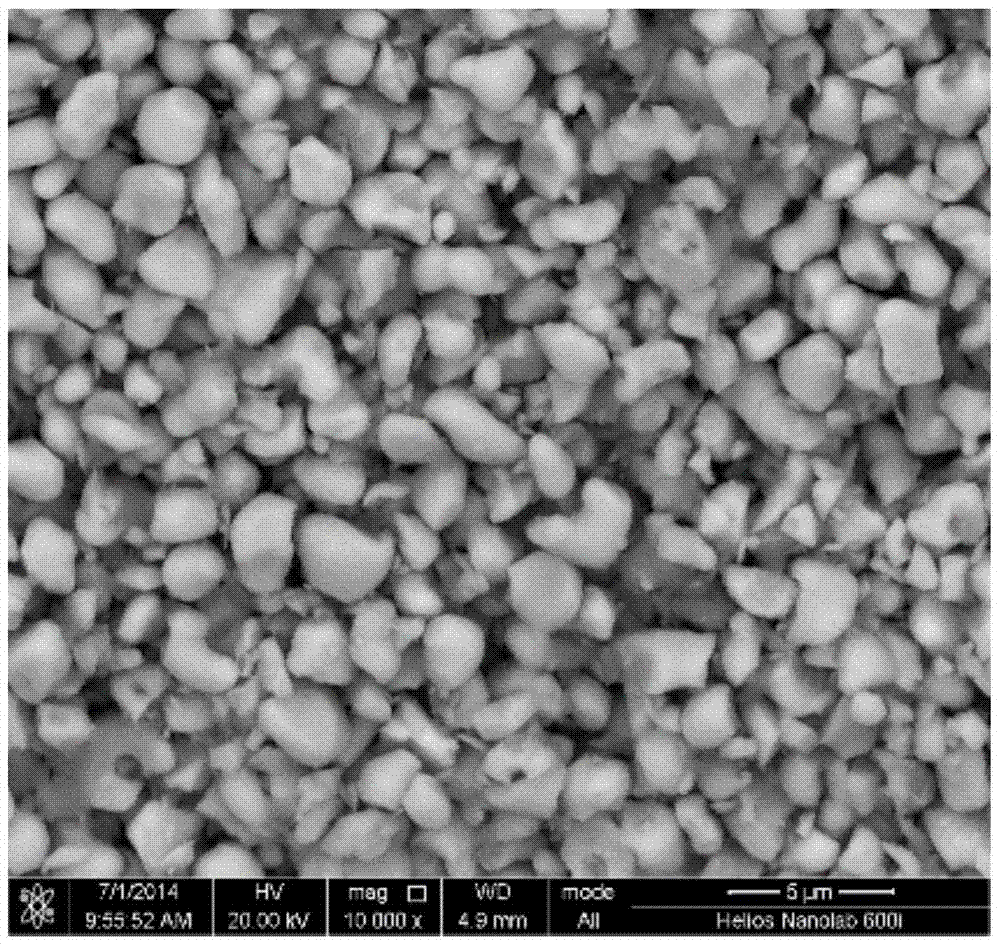

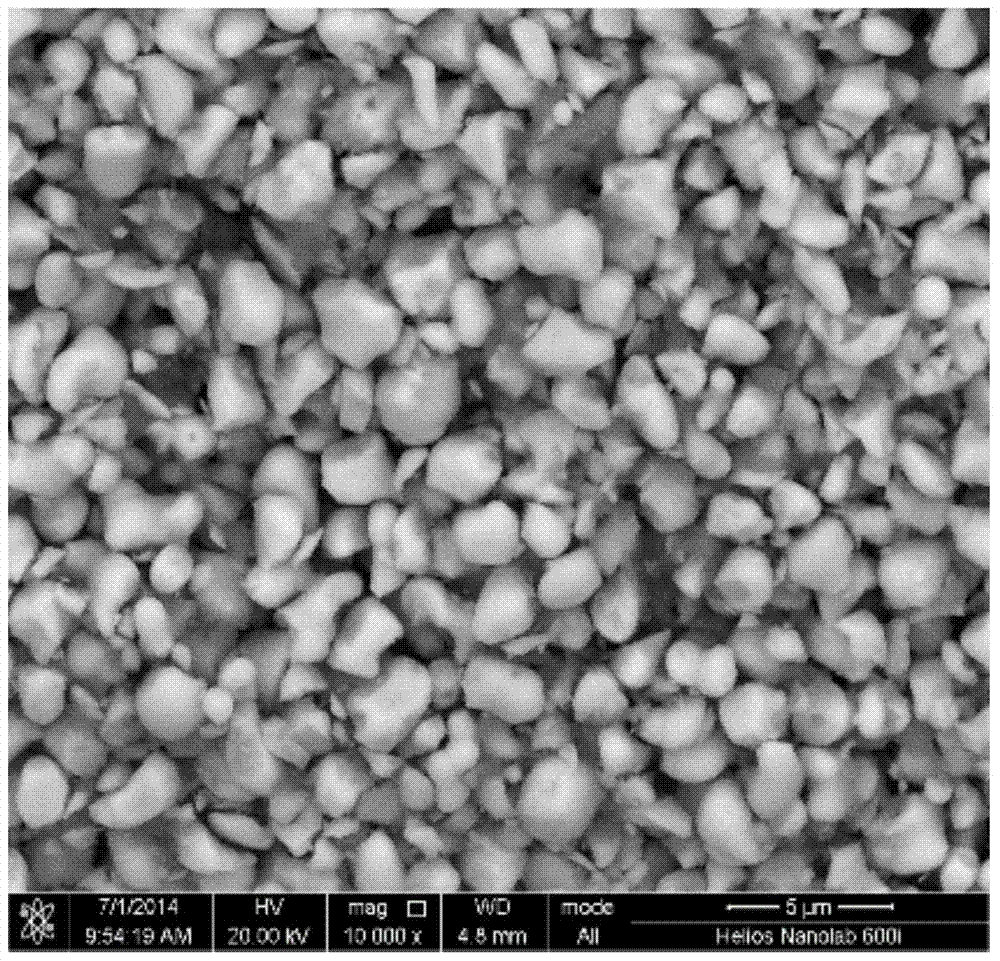

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the particle size of the ceramic powder in Step 2 is 0.1 μm˜10 μm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com