Automatic insertion pin grinding method and grinding machine

A technology of grinding machine and grinding mechanism, which is applied to vibration conveyors, grinding machines, conveyors, etc., can solve problems such as unfavorable product quality control, uneven pin grinding quality, and unfavorable mass production. performance, optimization of processing processes and procedures, and the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

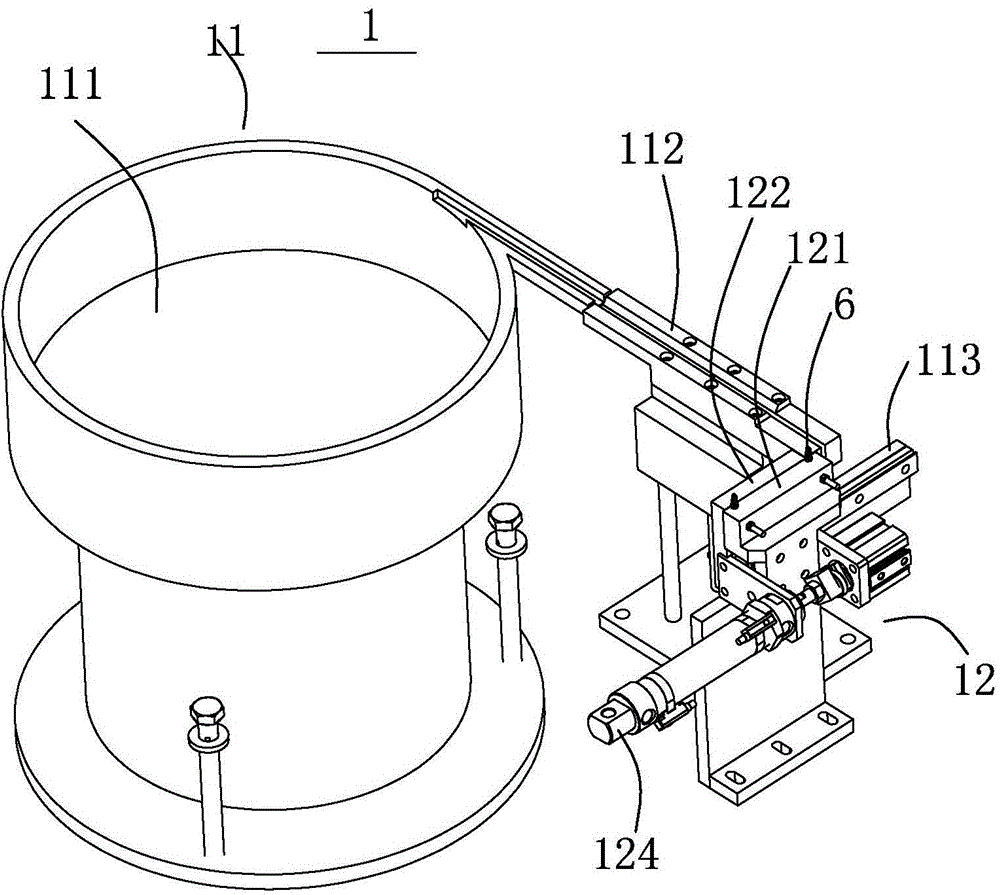

[0050] see Figure 1 to Figure 22 , the automatic pin grinding method provided by the present embodiment, which includes the following steps:

[0051] 1) A vibratory material selection mechanism 1 is set, and the vibratory material selection mechanism 1 includes a vibratory discharge assembly 11 and a moving material receiving assembly 12; Position assembly 22; a positioning detection mechanism 3 is provided, and the positioning detection mechanism 3 includes a divider turntable assembly 31, a pin detection assembly 32, and a defective rejection assembly 33; a material retrieving mechanism 4 is provided, and the retrieving mechanism 4 includes a material retrieving assembly 41. Feed and transposition assembly 42; a pin grinding mechanism 5 is provided, and the pin grinding mechanism 5 includes a belt roller assembly 51 and a grinding knife assembly 52; Each mechanism acts in coordination; wherein, the material grabbing mechanism 2 is arranged between the vibrating material se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com