Steel drum production process and corresponding four-station machining device thereof

A production process and processing device technology, applied in the field of four-station processing devices, can solve the problems of large floor area, low production efficiency, and high land cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

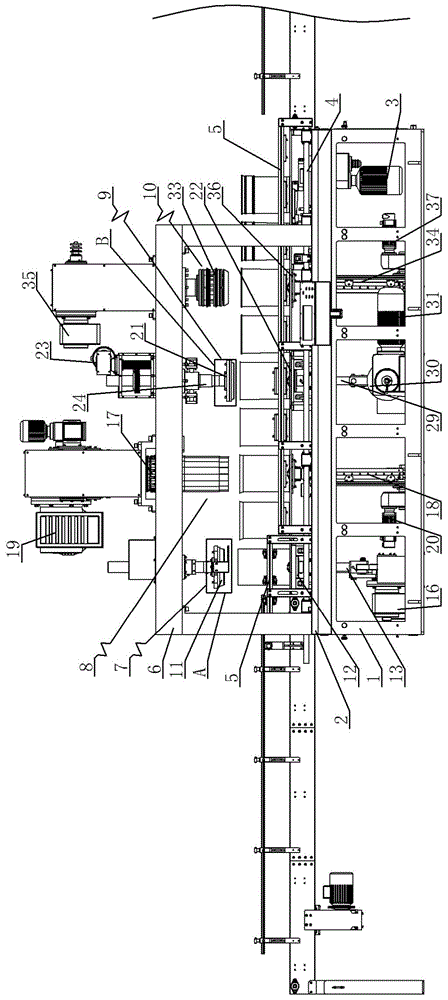

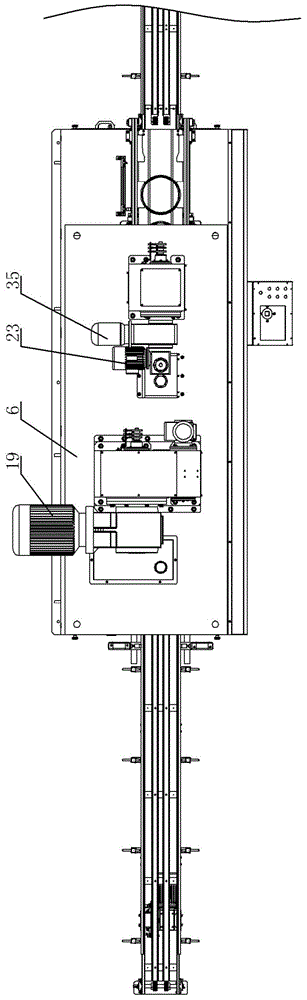

[0030] A steel drum production process, see Figure 1 to Figure 4 , which includes the following steps:

[0031] 1 The product first enters the welding machine, and the coil is welded;

[0032] 2. The barrel body is repainted inside and outside through the recoater;

[0033] 3 Drying by electromagnetic drying line;

[0034] 4 Air-dry and cool through the storage tank conveyor belt;

[0035] 5. Enter the four-station processing device, and pass through the flanging pre-rolling station, the cone expanding station, the coiling station, and the rib expanding station in turn;

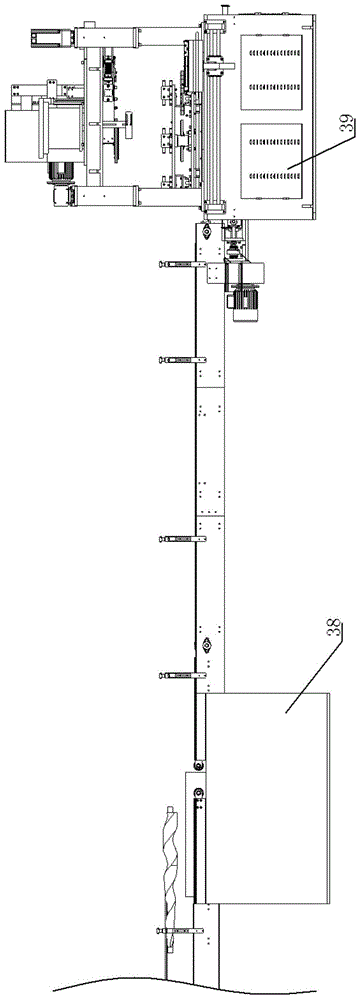

[0036] 6. Through the conveyor belt, convey the reinforced barrel to the non-turning back cover combination machine 38, and the bottom is back sealed;

[0037] 7 Send the back-sealed barrel to the automatic spot welding machine 39 through the conveyor belt, and the barrel ears are fitted with ears.

[0038] The above process is used to produce steel drums. The drums that have been air-dried and cooled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com