Coordinated type vibrating screen

A vibrating screen, linkage technology, applied in the direction of filter screen, solid separation, grille, etc., to achieve the effect of easy collection, low cost, and avoidance of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

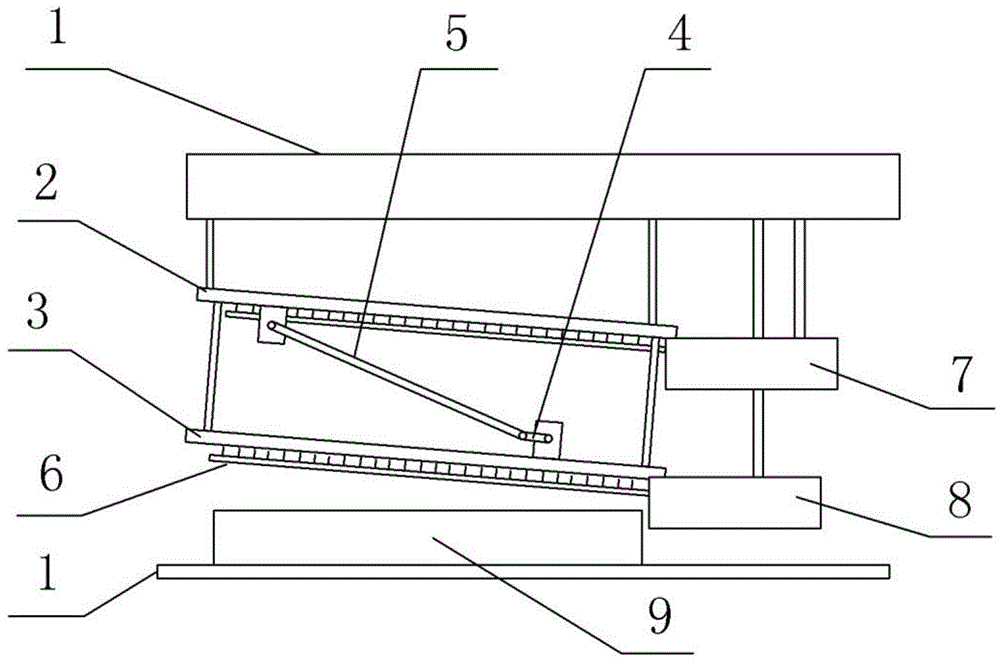

[0015] The reference signs in the accompanying drawings of the description include: frame 1, first screen 2, second screen 3, crank 4, connecting rod 5, dredging frame 6, first collection box 7, second collection box 8, the first Three collection boxes9.

[0016] Such as figure 1 As shown, a linkage vibrating screen in this embodiment includes a frame 1 and two layers of screens, the two layers of screens are divided into a first screen 2 located above and a second screen 3 located below, and the second screen 3 is located below. A screen 2 is connected to the frame 1 through a spring, a second screen 3 is connected to the first screen 2 through a spring, and a driving device is connected to the second screen 3 . It also includes a crank 4, a connecting rod 5, two dredging frames 6, a first collecting box 7 connected to the frame 1, a second collecting box 8 and a third collecting box 9. The first screen 2 and the second screen 3 are arranged obliquely relative to the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com