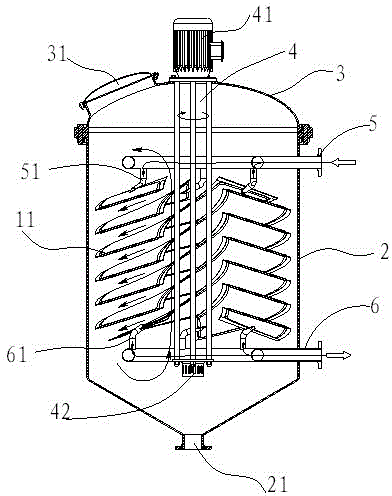

Stirring tank

A mixing tank and agitator technology, applied to mixer accessories, mixers with rotating agitating devices, dissolving, etc., can solve problems such as uneven heating or cooling of materials, unqualified products, unfavorable chemical and chemical processes, etc., to achieve improvement The effect of quality and uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

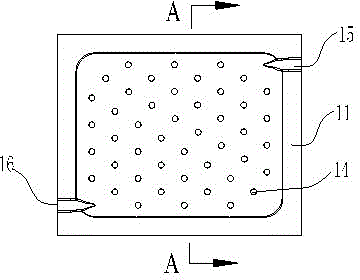

Examples

Embodiment 2

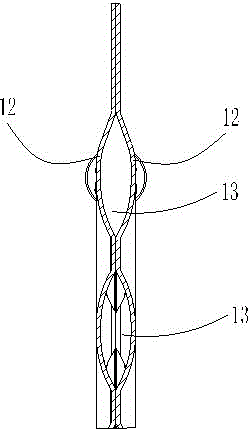

[0029] The difference from Example 1 is that, as Figure 4 and Figure 5 As shown, the structure of the hollow cavity 103 of the spiral heat exchange plate 101 is different from the structure of the hollow cavity in Example 1, and the spiral heat exchange plate 101 in Example 2 includes two stacked heat exchange The heat plate 102 is provided with a hollow cavity 103 after the two heat exchange plates 102 are stacked, and the hollow cavity 103 is as Figure 5 As shown, the welds of the two heat exchange plates 102 are welded into an S shape, so that the hollow cavity 103 of the heat exchange plate 101 is also set as an S-shaped flow channel, and the hollow cavity 103, the fluid inlet header 5 and the The fluid outlet header 6 forms a connected cavity, and the heat exchange plate 101 is arranged in a spiral shape. The fluid flows from the fluid inlet header 5 into the hollow cavity 103, and then flows out from the fluid outlet header 6. The S-shaped flow channel The contact a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com