Filter material for sewage treatment and preparation method for filter material for sewage treatment

A technology of sewage treatment and filter material, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of poor nutrient element removal, poor biofilm adhesion, single function, etc. problems, to achieve the effect of simple and convenient operation, increase the mass transfer rate, and shorten the sewage treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0032] In the research on the preparation method of the filter material of the present invention, the inventors carried out the following test process to determine the optimal control parameters in the filter material preparation method.

[0033] (1) Raw material selection and preparation

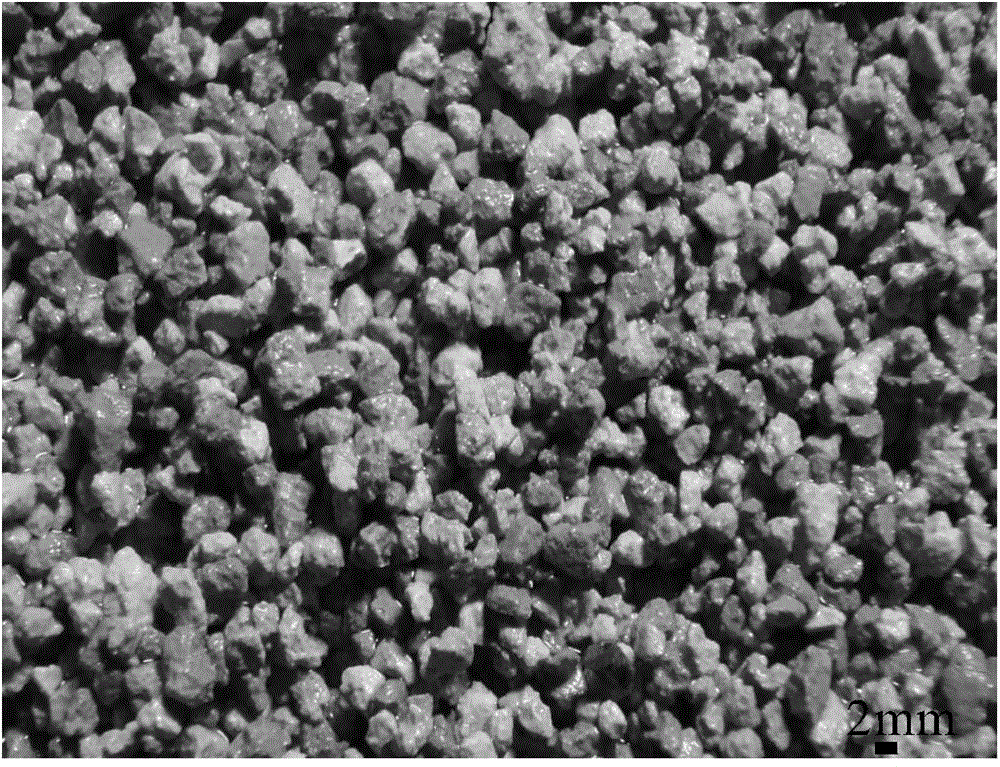

[0034] The applicant found through research that deer marsh soil is a rare substance, which is produced in volcanic areas and is formed from the lower volcanic soil. It has high permeability, water storage capacity and air permeability. Kanuma soil is not very uniform in size and has many holes. Therefore, deer marsh soil is selected as one of the raw materials for the preparation of filter media. In the firing process, an appropriate amount of clay is introduced to improve the mechanical strength and relative specific gravity of the filter material. At t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com