Paper diaper capable of preventing absorption bodies from cracking and production method of paper diaper

A production method and technology for an absorbent body, which are applied in the field of diapers, can solve the problems of high cost of puffed composite cores, easy generation of side leakage and rear leakage, and increased weight of diapers, so as to improve infiltration and diversion speed and diffusion area. , The effect of preventing side leakage and rear leakage, and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

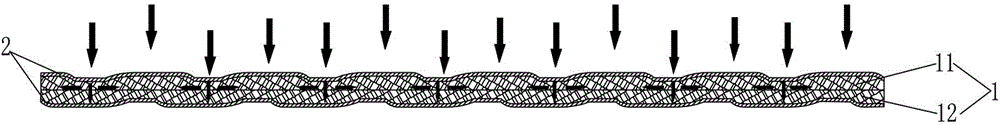

[0026] See Figure 1-Figure 2 As shown, a diaper for preventing absorber breakage according to the present invention comprises an absorbent part 1 and an outer layer 2 covering the absorbent part 1, and the outer layer 2 is a non-woven fabric; the diaper includes at least two layers of absorbent Sections 11, 12; the absorption sections 11, 12 include several independent absorbers 10 arranged at intervals and formed by hot pressing or glue spraying; the absorbers 10 are absorbers mixed with wood pulp and polymer water-absorbing agents; wherein The absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com