Preparation method of Nisin double layer microcapsule suitable for high temperature baking food

A technology of high-temperature baking and microcapsules, which is applied in the preservation, baking, and application of baked products to achieve the effects of improving antibacterial activity, protecting antibacterial stability, and simplifying processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

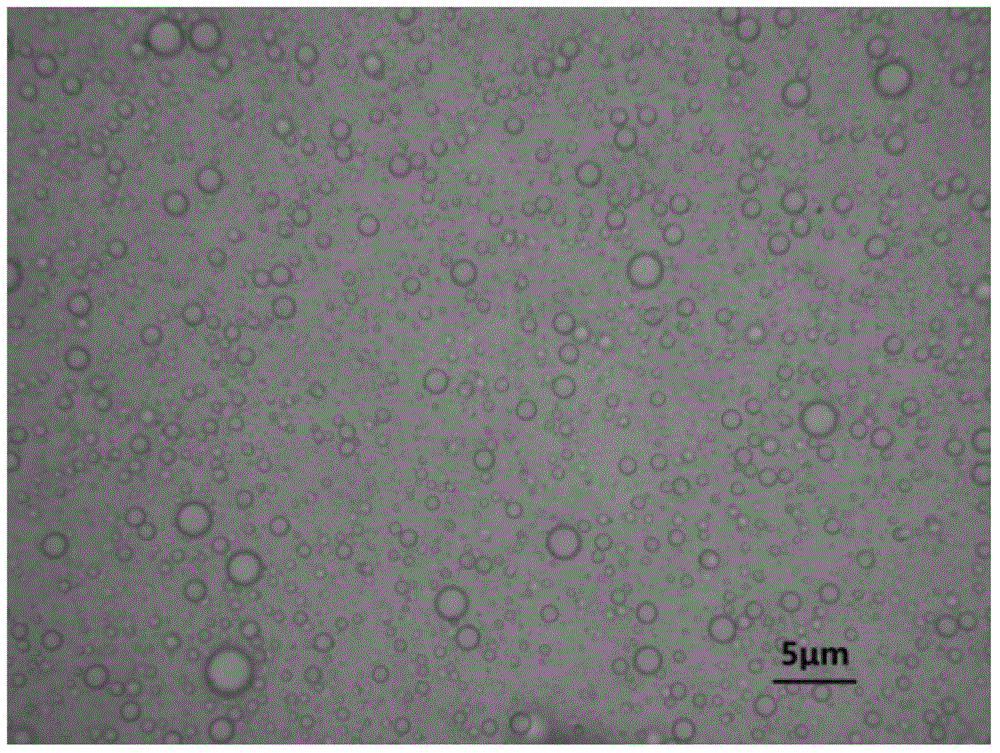

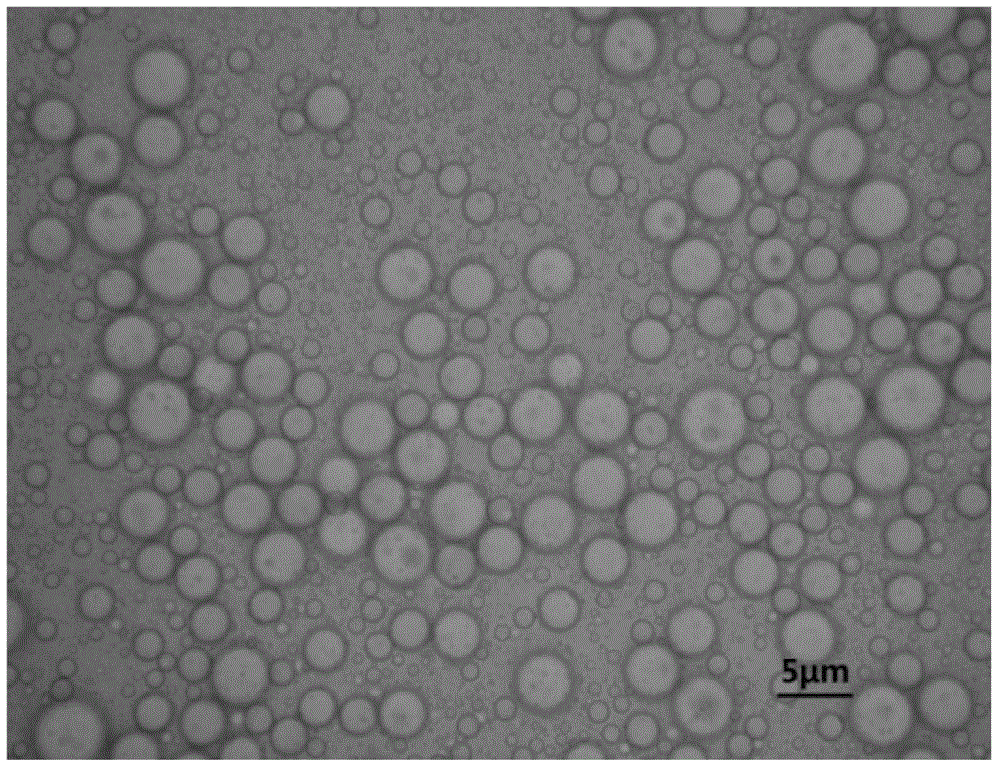

Image

Examples

preparation example Construction

[0024] (1) Preparation of chitosan raw gum solution: prepare 0.2-1wt% chitosan aqueous solution, add volume fraction of 0.5-2% glacial acetic acid to fully dissolve chitosan;

[0025] (2) Preparation of Nisin Chitosan Emulsion: Add Nisin to the original gum solution at a mass ratio of 1:1 to 10 to chitosan, mix well and filter, adjust the pH of the solution to 2.5 to 5.5, and then add 1.2 to 5mL / L Tween-80, 0.12-1.00g / L PEG, homogenize for 20-60 minutes until fully mixed to form a uniform emulsion;

[0026] (3) Encapsulation of microcapsules: Slowly add sodium tripolyphosphate solution dropwise in the mixed solution described in step (2), control the mass ratio of chitosan to sodium tripolyphosphate to be 1:3~10, the preparation process keeps The stirring speed is 200-400rpm and the temperature is 25-60°C, and the solidified capsules are continuously stirred for 20-60 minutes to obtain Nisin chitosan microcapsules;

[0027] (4) Washing and drying: wash the microcapsules with ...

Embodiment 1

[0032] A preparation method of Nisin chitosan microcapsules, the steps are as follows:

[0033] (1) Get 0.5g chitosan and be dissolved in 250mL distilled water, add volume fraction and be 1% glacial acetic acid and fully dissolve;

[0034] (2) Add Nisin with a chitosan mass ratio of 1:4 to the original gum solution, filter and remove incompatible substances after mixing evenly to form a mixed solution, and adjust the pH of the solution to 5.5;

[0035](3) Add 700μL Tween80 and 0.05gPEG, mix and homogenize for 30min until fully mixed to form a uniform emulsion; then slowly add sodium tripolyphosphate solution with a mass ratio of 1:5 to chitosan into the mixture During the preparation process, the temperature was kept at 25°C, the rotation speed was 300rpm, and the stirring was continued for 30 minutes to obtain the Nisin chitosan microcapsules;

[0036] (4) Wash the microcapsules with a distilled aqueous solution containing 1.5% (w / v) Tween-80, dialyze overnight, and dry them...

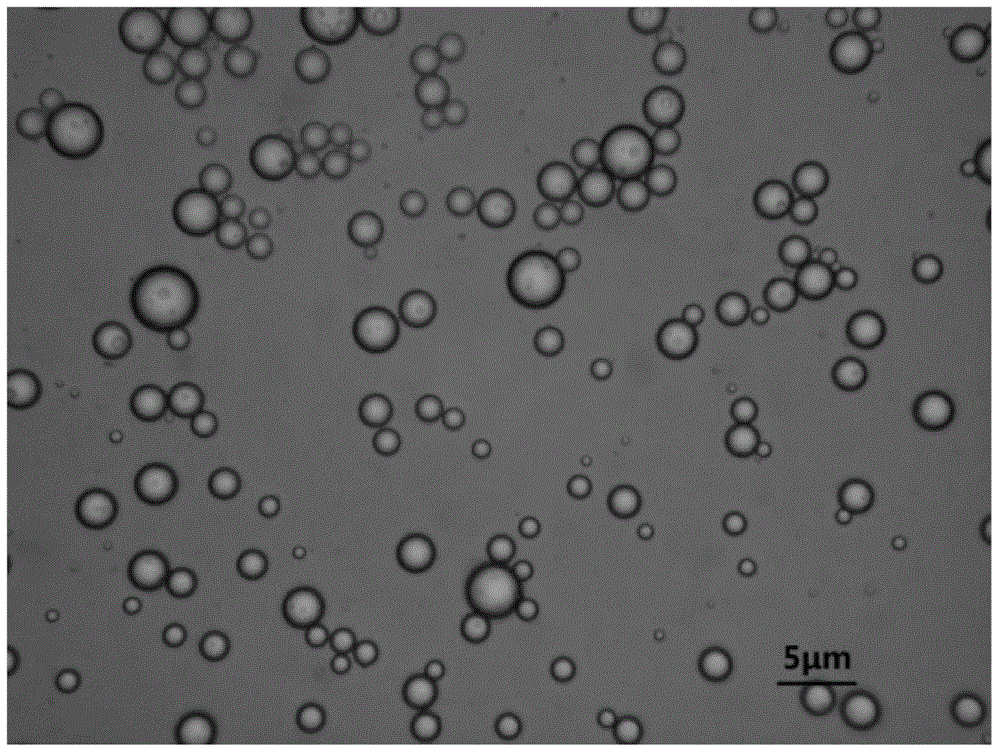

Embodiment 2

[0042] A preparation method of Nisin chitosan microcapsules, the steps are as follows:

[0043] (1) Get 0.5g chitosan and be dissolved in 250mL distilled water, add volume fraction and be 0.5% glacial acetic acid and fully dissolve;

[0044] (2) Add Nisin with a chitosan mass ratio of 1:1 to the original gum solution, filter and remove incompatible substances after mixing evenly to form a mixed solution, and adjust the pH of the solution to 4.5;

[0045] (3) Add 300 μL Tween80 and 0.1g PEG, mix and homogenize for 30 minutes until fully mixed to form a uniform emulsion; then slowly add sodium tripolyphosphate solution with a mass ratio of 1:4 to chitosan into the mixture During the preparation process, the temperature was kept at 30°C, the rotation speed was 300rpm, and the stirring was continued for 30 minutes to solidify the capsules to obtain Nisin chitosan microcapsules;

[0046] (4) The microcapsules were washed with distilled aqueous solution containing 1.5% (w / v) Tween8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com