False sticking equipment

A technology of equipment and false stickers, which is applied in the direction of electrical components, laminated printed circuit boards, printed circuit manufacturing, etc., can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

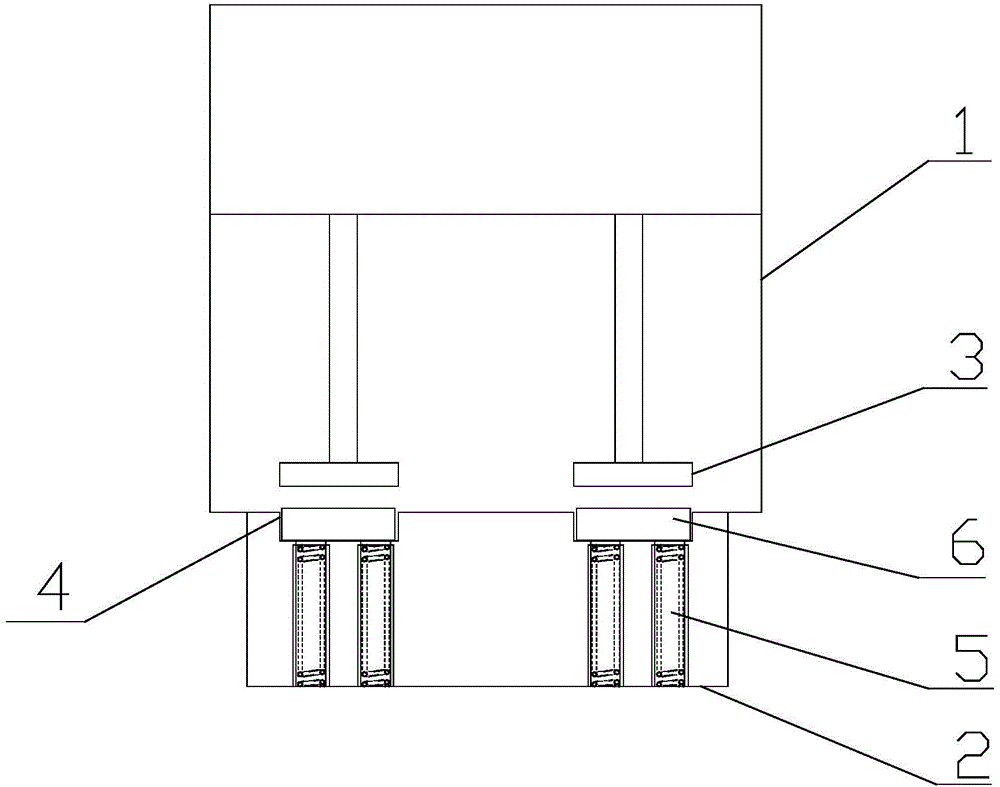

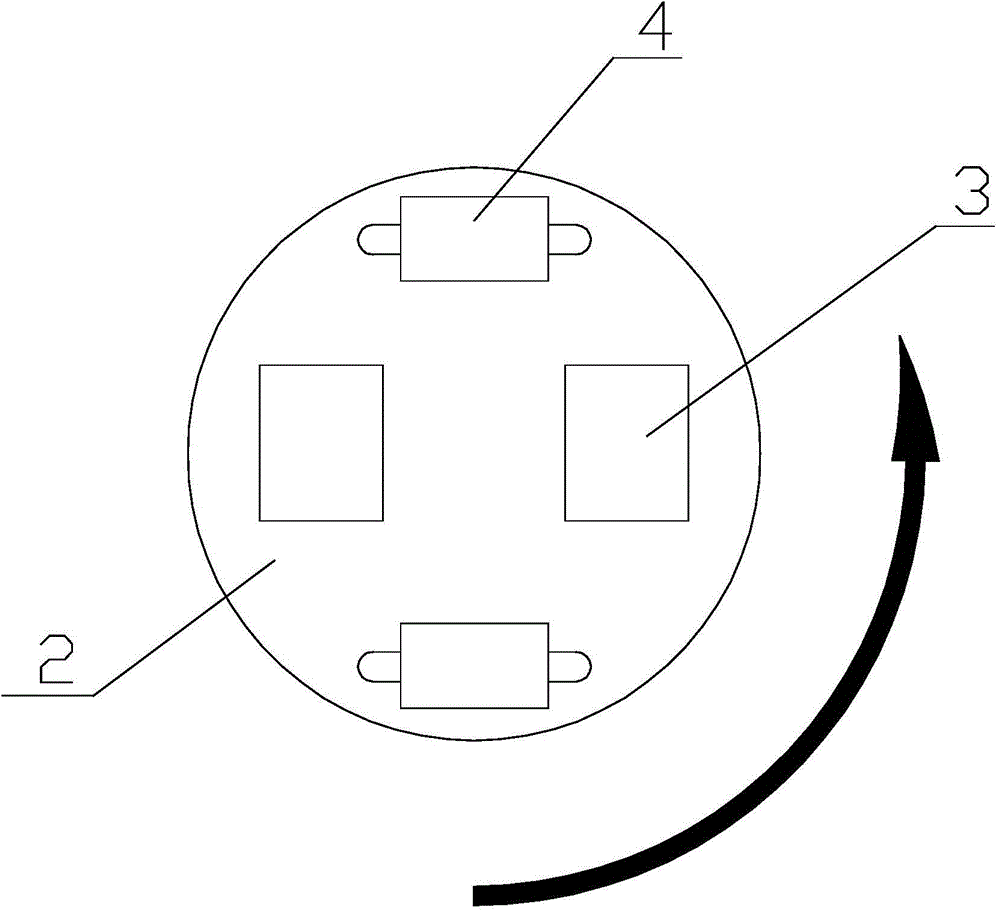

[0011] Such as figure 1 with figure 2 The false pasting equipment shown includes: a rotating table 1 and a base 2 . The rotary table 1 is provided with a hot pressing block 3 . The base 2 is provided with a hot-pressing groove 4, and the bottom of the hot-pressing groove 4 is provided with a spring thimble 5. The functions of the spring thimble 5 are: 1. to keep the reinforcement sheet and the heat-pressed block tightly when they are attached; 2. to prevent the reinforcement sheet from being damaged. Overstressed. The turntable 1 can rotate, rise and fall, and align the hot-press block 3 with the hot-press groove 4 .

[0012] In order to fit the reinforcement sheets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com