Power conversion equipment and electric power steering equipment having power conversion equipment

A technology of power conversion and equipment, applied in the field of electric power steering equipment, can solve problems such as inability to properly perform current detection, and achieve the effect of simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

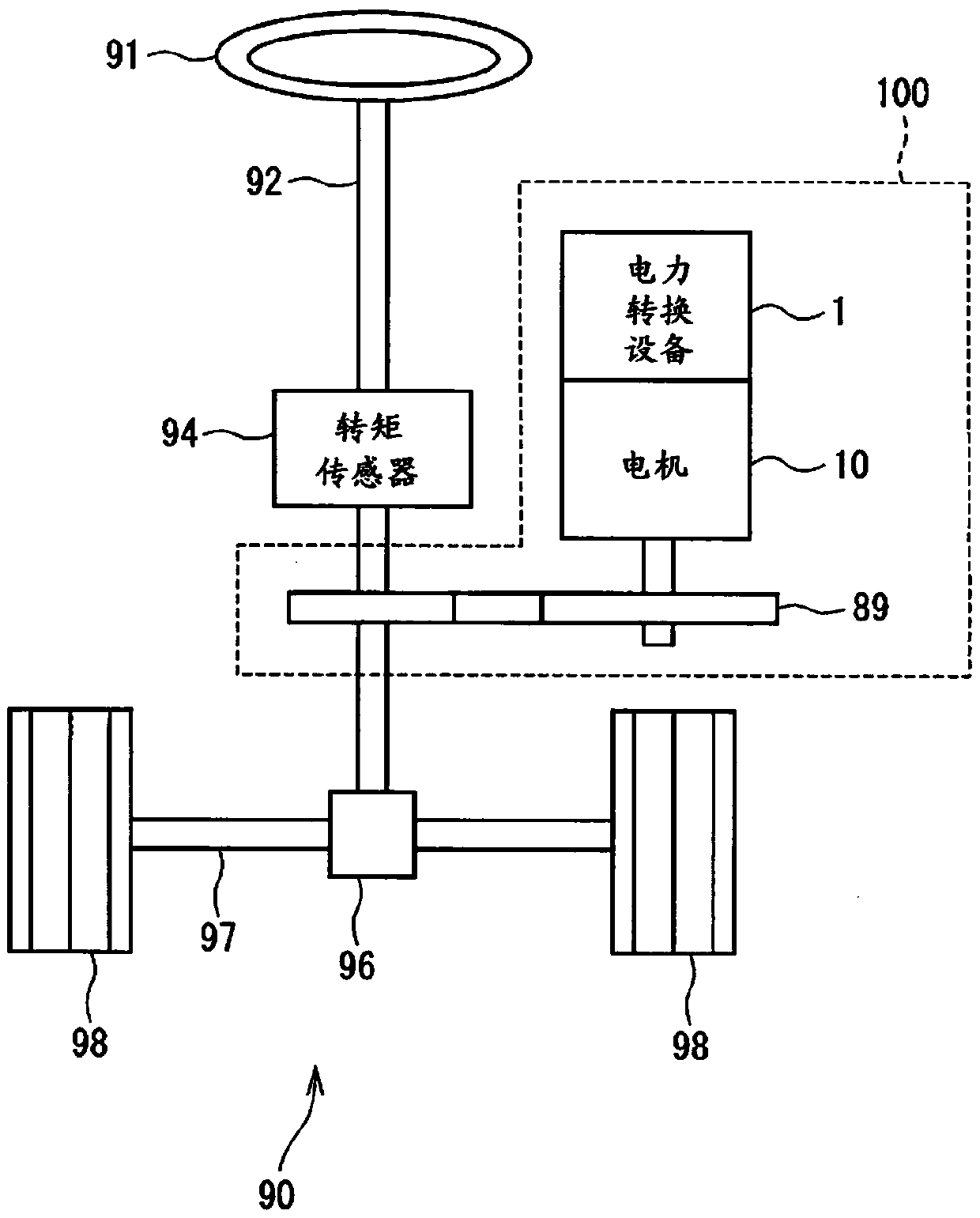

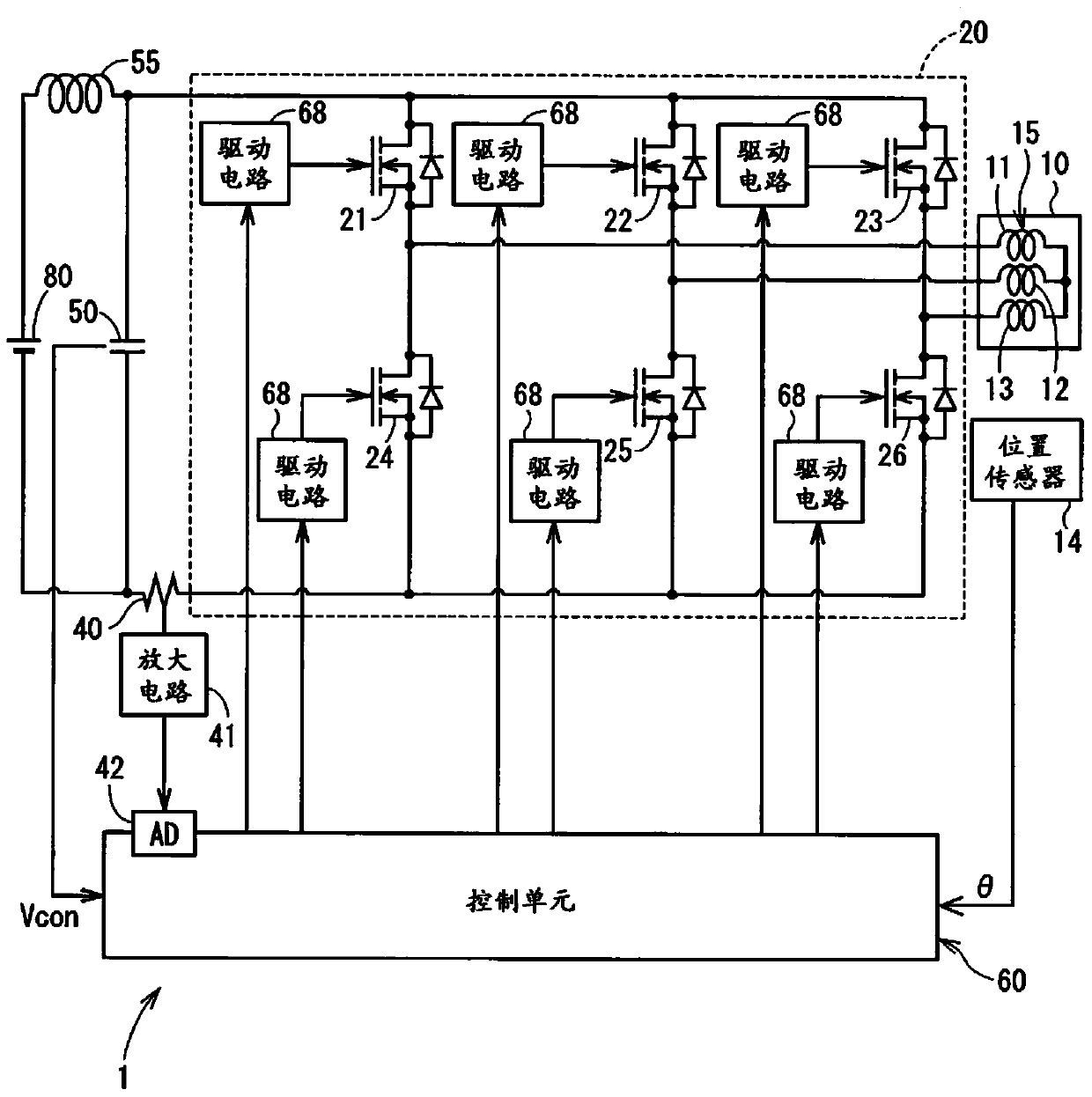

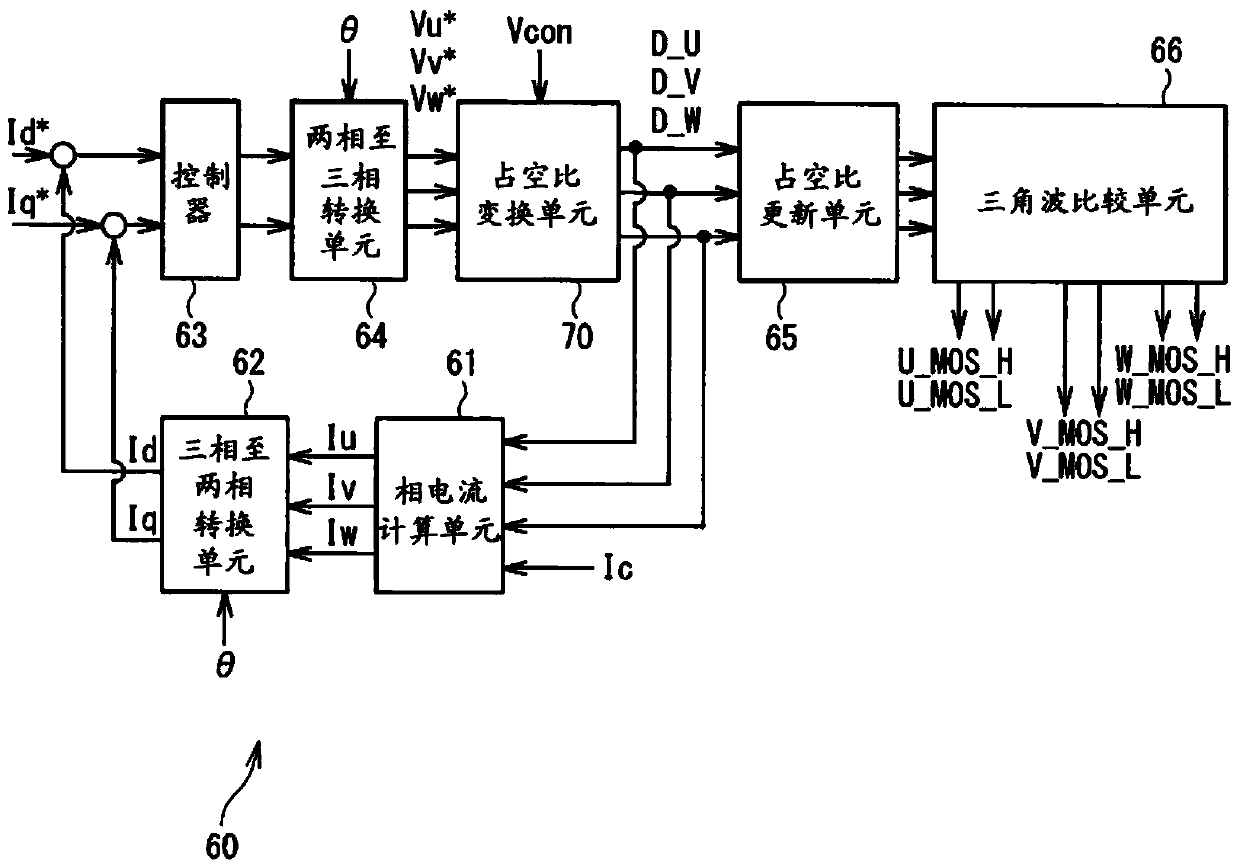

[0037] Figure 1 to Figure 21 A power conversion device according to a first embodiment of the present disclosure and an electric power steering device using the same are shown. Hereinafter, the same reference numerals are used for substantially the same configurations in various embodiments, and descriptions thereof will not be repeated.

[0038] like figure 1 As shown, the power conversion device 1 is applied to, for example, an electric power steering device 100 for assisting a steering operation of a vehicle together with an electric machine 10 as a rotating electric machine.

[0039] figure 1 An overall configuration of a steering system 90 having an electric power steering apparatus 100 is shown. The steering system 90 is constituted by a handle (steering wheel) 91, a steering shaft 92, a pinion 96, a rack shaft 97, wheels 98, an electric steering apparatus 100, and the like.

[0040] The handlebar 91 is connected to a steering shaft 92 . The steering shaft 92 is pr...

no. 2 approach

[0320] will refer to Figure 22 A second embodiment of the present disclosure is described. Since the second embodiment differs from the first embodiment regarding the current control period. Differences will be mainly described.

[0321] In the first embodiment, the currents Iu, Iv, and Iw of the respective phases are calculated every two cycles, and current control is performed.

[0322] like Figure 22 As shown, in the second embodiment, current control is performed every four cycles. Specifically, phase current calculation unit 61 calculates V-phase current Iv based on the average value of current detection values Iv(+) and Iv(−) detected in the second cycle. Phase current calculation unit 61 also calculates W-phase current Iw based on the average value of Iw(−) and Iw(+) detected in the third cycle. The U-phase current Iu is calculated by "sum of three phases=0".

[0323] Based on the calculated currents Iu, Iv, and Iw of each phase, calculate the duty ratio comma...

no. 3 approach

[0326] In the foregoing embodiment, the current detection value when correction is made in the positive direction in one PWM period and when The current detection value when correction is made in the negative direction in one PWM cycle, the center current Ia is calculated, and current control is performed based on the center current Ia.

[0327] On the other hand, when the magnitude of the voltage command values Vu*, Vv*, and Vw* is equal to or greater than the first predetermined value THa1, based on the case of correcting the duty ratio to the positive side or the case of correcting the duty ratio to the negative side To calculate the current Iu, Iv and Iw of each phase, so that the distortion of the current waveform cannot be corrected.

[0328] Thus, in the embodiment, the correction factor Y is calculated when the magnitude of the voltage command values Vu*, Vv*, and Vw* is smaller than the first predetermined value THa1. Based on the calculated correction factor Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com