Follow-up flattening device for material coiling

A technology of transmission device and coil material, which is applied in the directions of coiling strips, thin material handling, transportation and packaging, etc., which can solve the problems of low production efficiency and poor processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

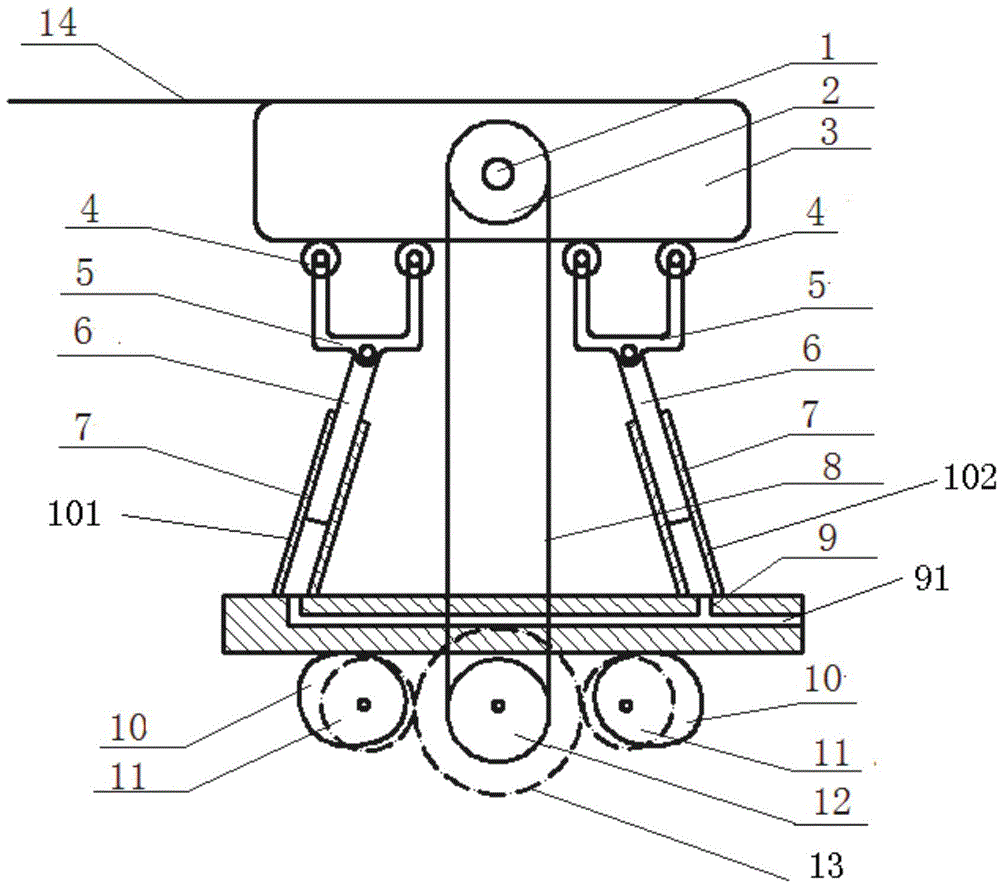

[0021] like figure 1 Shown, a kind of roll material follow-up flattening device, it comprises:

[0022] Coil spindle 1, which is used to drive the coil workpiece 3 to rotate to realize the coiling of the foil 14;

[0023] Pressing plate 9, which is connected to coil material main shaft 1 through a pressing plate follow-up transmission mechanism, when winding main shaft 1 rotates, pressing plate 9 swings up and down so that pressing plate 9 and the lowermost end of rotating coil material workpiece 3 keep synchronous movement;

[0024] Adaptive pressing part, the self-adapting pressing part includes a telescopic power part 7 and a pressure roller assembly, the fixed end of the telescopic power part 7 is installed on the pressure plate 9, and the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com