Medicine bottle cap injection mold, production method thereof and bottle cap product

A technology for injection molds and products, which can be applied to home appliances, other home appliances, household components, etc., can solve the problems of lowering the ease of use of medicine bottles, safety of filling, unsatisfactory compression fit, damage, etc., to achieve Adaptive compression effect, improvement of suppression of shaking and misalignment, and effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

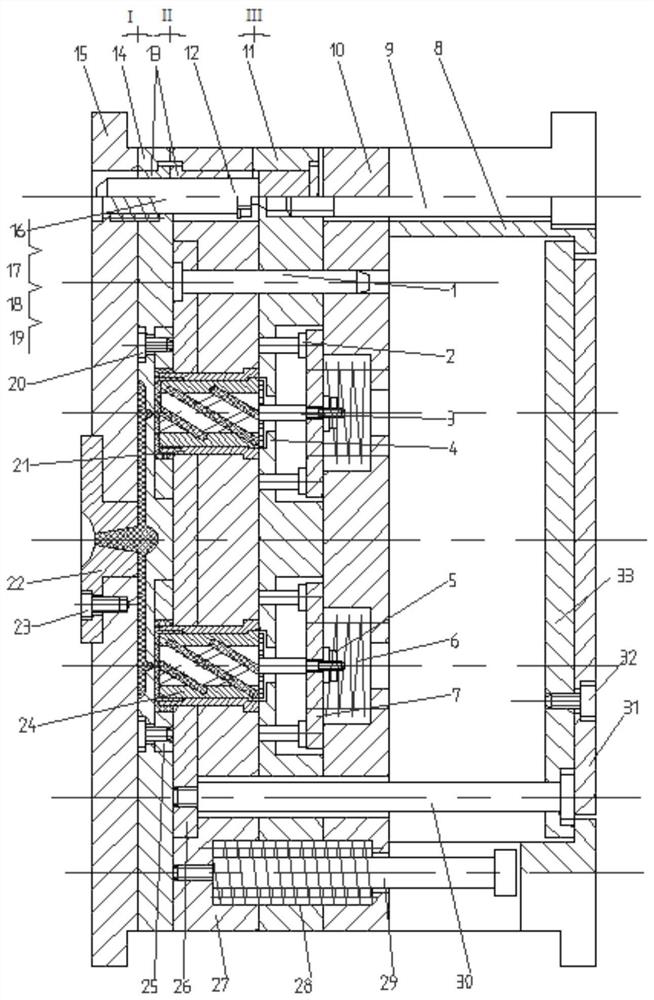

[0026] Such as figure 1 Shown, a kind of medicine bottle cap injection molding mold comprises the fixed mold base assembly and the movable mold base assembly that cooperate with each other; Described fixed mold base assembly comprises fixed mold base plate 15 and cavity plate 14; Described fixed mold base plate 15 The interface with the cavity plate 14 constitutes the first parting surface; the first parting surface corresponds to the position of the runner; the end of the runner is provided with an oblique pulling hole; the fixed mold seat A distance tie rod 16 is arranged between the assembly and the movable mold seat assembly; a washer 18 is arranged on the distance tie rod 16; the movement of the washer 18 and the cavity plate 14 away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com