Cable manufacturing equipment

A technology for manufacturing equipment and cables, which is applied in the field of cable manufacturing equipment to achieve the effects of increasing the length of storage lines, increasing the speed of pay-off, and improving the efficiency of cable manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

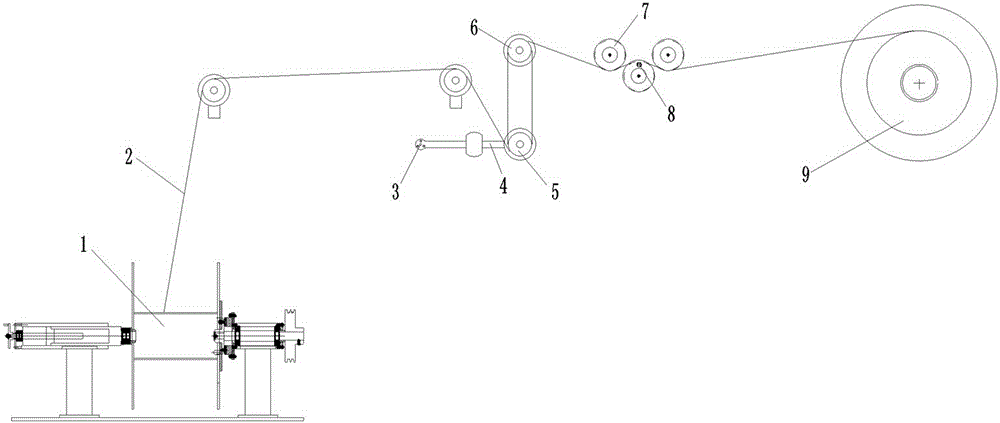

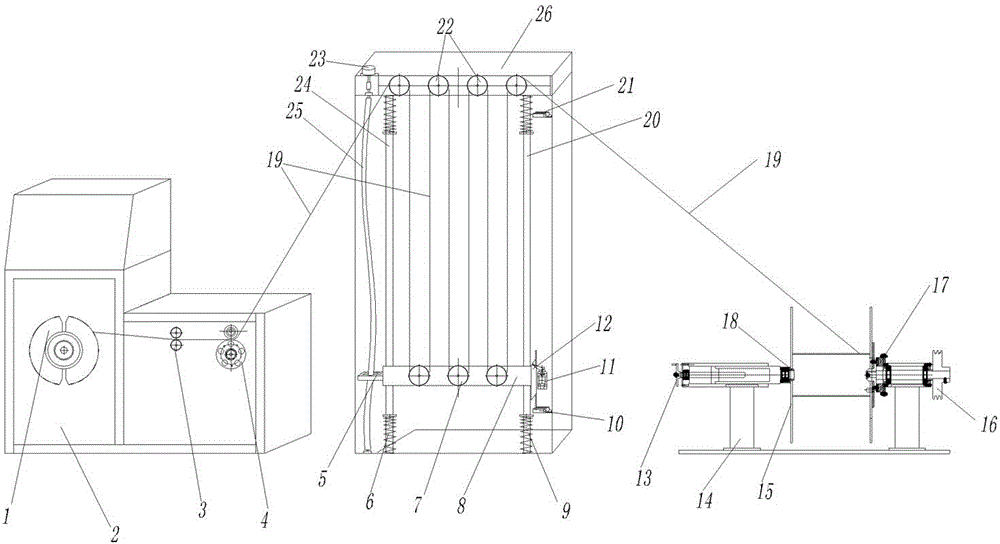

[0013] Examples of cable manufacturing equipment are figure 2 Shown: it includes a wire storage device, a pay-off reel and a take-up reel, the pay-off reel is provided with a brake pad 17, the pay-off reel is connected to the pay-off drive mechanism through the pay-off drive pulley 16, and the pay-off reel is arranged on the pay-off On the reel frame 14, the pay-off reel frame is provided with a pay-off reel top-tight handle 13 and a pay-off top cone 18; the take-up reel 1 is arranged on the take-up reel frame 2, and the take-up reel frame 2 is provided with a wire arrangement 3 and a pair of pressure rollers 4, the pressure rollers are assembled on the take-up reel frame 2 through a one-way bearing, and one of the pressure rollers is a meter pressure roller provided with a meter meter proximity switch. After the cable is drawn out from the pay-off reel, it is wound around the fixed reel and the movable reel of the cable storage in turn, and finally drawn out through the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com