Control line pay-off machine

A technology for controlling lines and pay-off machines, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of manual pay-off, many employees, and high labor intensity, and achieve the number and length of pay-off lines. Accurate, fast pay-off speed and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

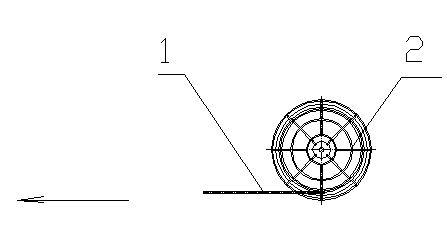

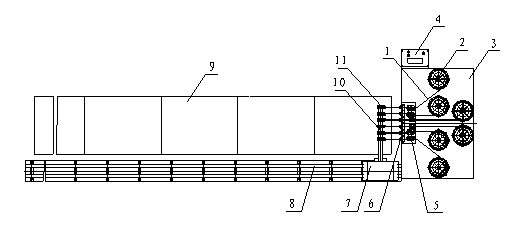

[0011] Such as figure 2 As shown, the pay-off machine of the present invention is mainly composed of 1 workbench 3, at least 6 wire extenders 5 and 6 bolt cutters 6, 1 trolley 7, 1 track 8, 1 storage table 9, and 1 Pay-off rack 10, 6 wire clamps 11, 1 control box 4 form. The control box 4 is installed on the side of the workbench 3, and the control box 4 is equipped with electrical control components including a computer to ensure automatic control of the pay-off machine and automatic pay-off; the rectangular workbench 3 is provided with at least 6 pay-off racks 2. The pay-off frame 2 includes a base and a turntable, and the turntable can be rotated; the side of the workbench 3 is equipped with wire extenders 5 equal in number to the pay-off frame 2, and each wire extender 5 has 2 tensioning wheels for control The line 1 plays a certain tensioning effect; the outer surface of the workbench 3 is equipped with bolt cutters 6 equal to the number of the pay-off frame 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com