Direct coal liquefaction reaction kinetic model modeling method

A technology of direct coal liquefaction and reaction kinetics, applied in special data processing applications, preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve problems such as inability to accurately predict liquefied oil and gas components in direct coal liquefaction reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

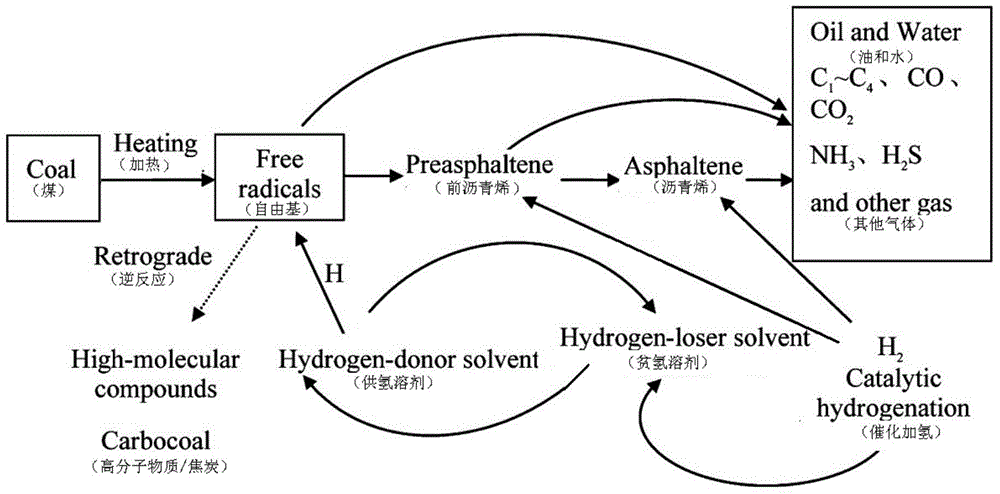

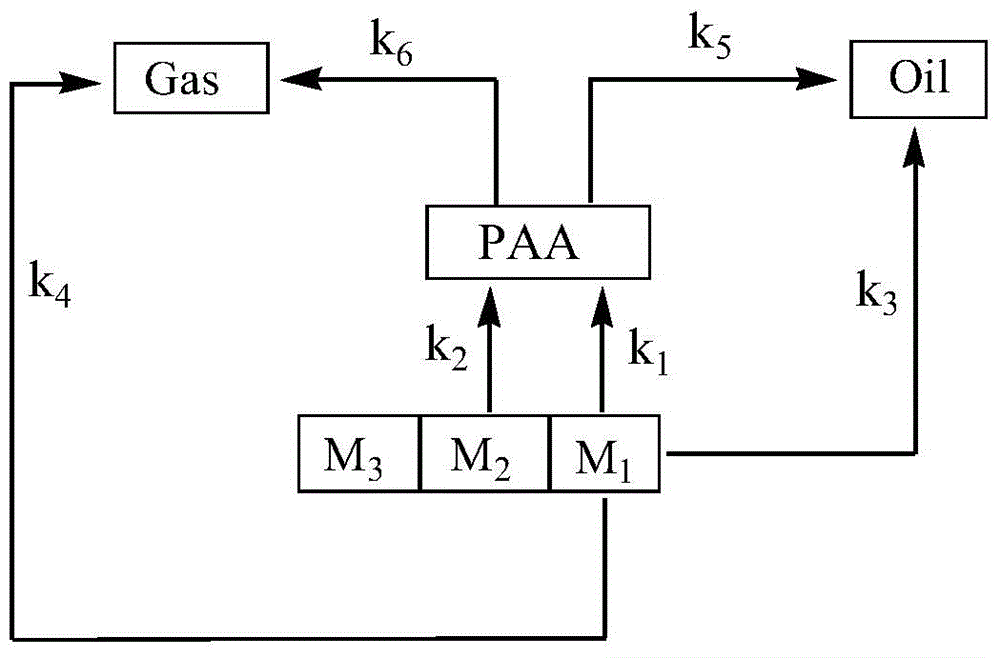

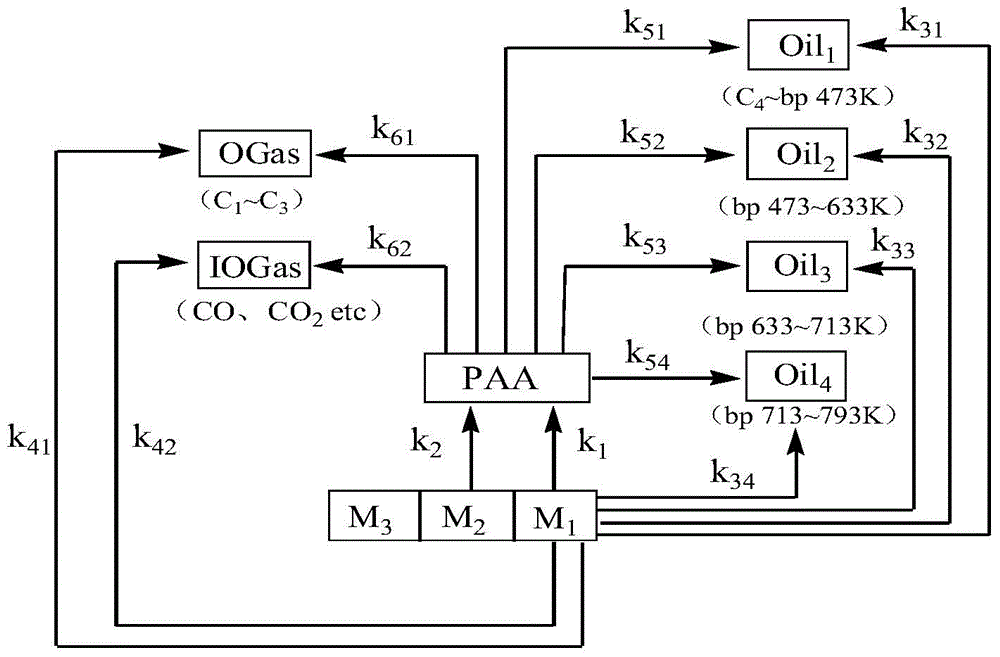

[0042] According to an embodiment of the present invention, a method for modeling a kinetic model of a direct coal liquefaction reaction is provided. The modeling method of the direct coal liquefaction reaction kinetic model includes: step S1: dividing raw coal, intermediate products of coal direct liquefaction reaction and liquefied oil into 11 aggregates; step S2: constructing the reaction mechanism according to the reaction mechanism of direct coal liquefaction network; step S3: establish the differential equation of the coal direct liquefaction reaction model according to the reaction network; step S4: solve the coal direct liquefaction reaction model differential equation, determine the parameters in the coal direct liquefaction reaction model d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com