A Method of Improving the Accuracy of Process Data Analysis of Feeding Machine

A process data and analysis accuracy technology, applied in program control, electrical program control, program control in sequence/logic controllers, etc., can solve the problems of data loss, inability to accurately analyze feeding process data, etc. Optimize the feeding process and the effect of high-precision acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

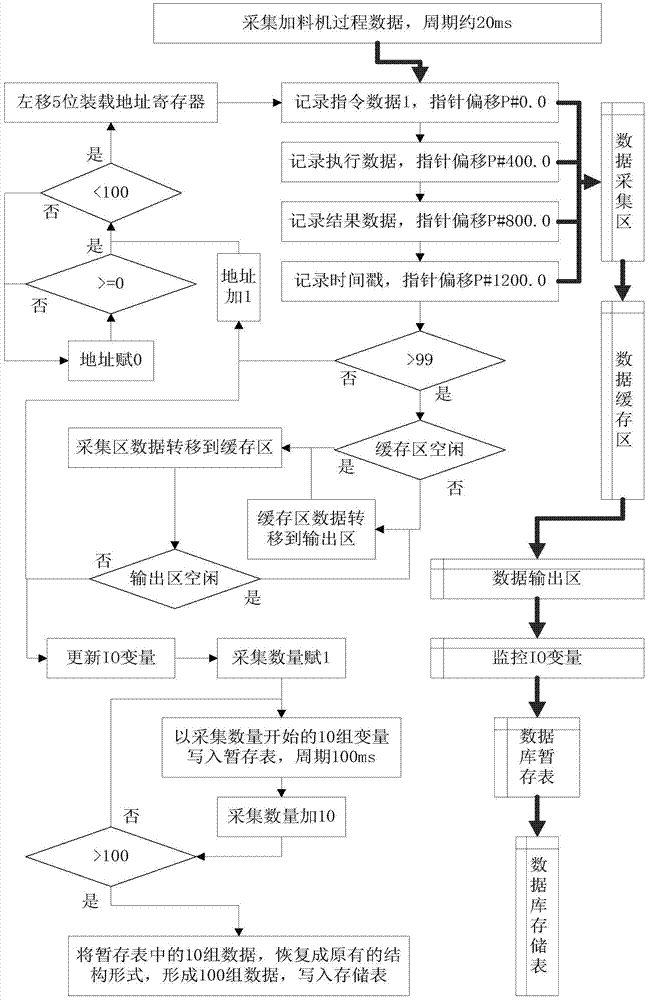

[0024] Such as figure 1 As shown, a method for improving the accuracy of feeder process data analysis includes the following steps:

[0025] Step 1 calculates the stack address pointer.

[0026] P=I*32+P#

[0027] P: address pointer;

[0028] I: address serial number;

[0029] P#: Pointer offset.

[0030] Step 2 Query the current time of the PLC in real time, obtain the 5 bytes of hour, minute, second, 10 milliseconds, and 0.1 milliseconds of the current time, convert the BCD code in the byte into an integer, and calculate a time value in units of 0.1 milliseconds , as the data collection time, and saved together with the monitoring data for later analysis.

[0031] t=(((h*60+m)*60+s)*100+ms 1 )*100+ms 2

[0032] t: data collection time;

[0033] h: the hour in the current time of the PLC;

[0034] m: minute in PLC current time;

[0035] s: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com