Digital display touch controller of full-automatic feeder

A feeding machine and controller technology, applied in the field of digital display touch controller, can solve the problems of low timing precision of mechanical timer, rusted gear timing, no automatic control, etc., to achieve scientific and reasonable High performance, reduced maintenance troubles, and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

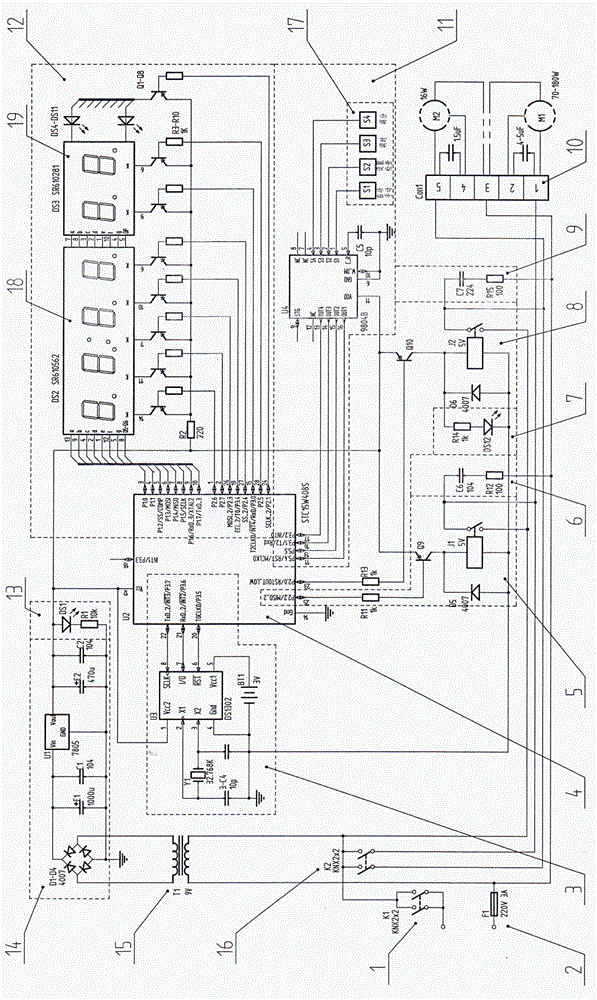

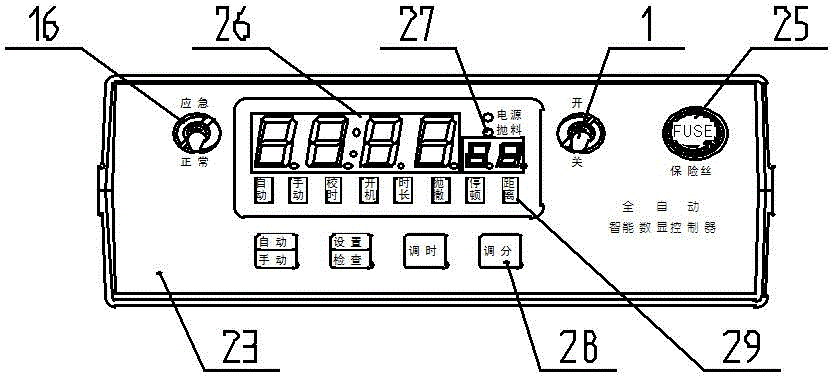

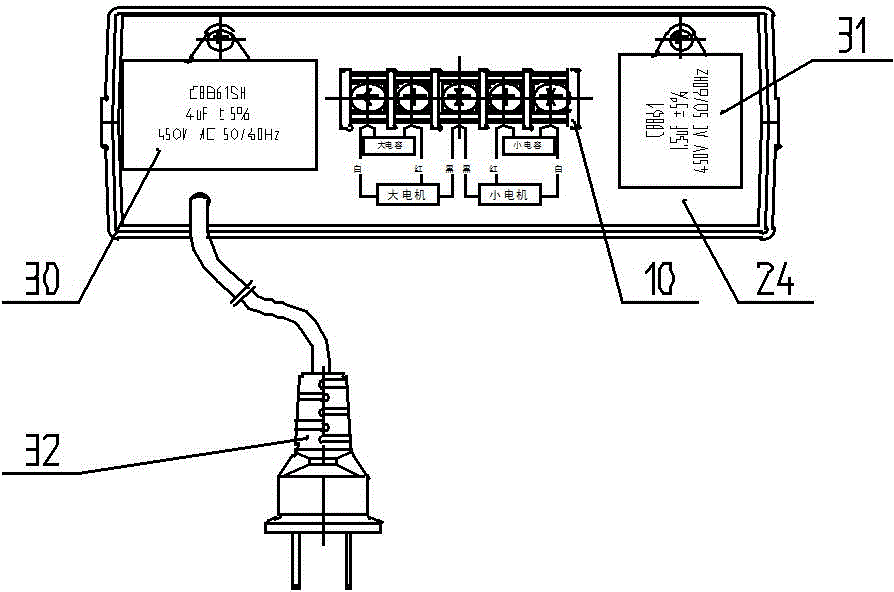

[0012] Such as Figure 1-4 As shown, the electrical circuit of the controller consists of a power switch 1, an insurance circuit 2, a clock circuit 3, a relay J1 drive protection circuit 5, a relay J1 contact protection circuit 6, a material throwing indication circuit 7, a relay J2 drive protection circuit 8, Relay J2 contact protection circuit 9, touch input setting circuit 11, display drive circuit 12, power indicator circuit 13, rectification and voltage stabilization circuit 14, transformer 15, emergency switch 16, terminal 10 are connected to form, wherein: insurance circuit 1 is composed of fuse Block 25 and the fuse inserted into the inner cavity of the fuse block 25; the clock circuit 3 is composed of 3 ports 20-22 of the single-chip microcomputer 4U2, clock chip U3, crystal oscillator Y1, capacitors C3-C4 and rechargeable battery BT1; relay J1 drives the protection circuit 5 is composed of a port 25 of the single-chip microcomputer 4U2, resistor R11, transistor Q9, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com