Main stress application device for true triaxial apparatus

A technology of application device and tester, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problem of low stiffness of flexible filler, distortion of test results, enlargement of sample and pressure plate Friction and other problems, to solve the effect of excessive friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

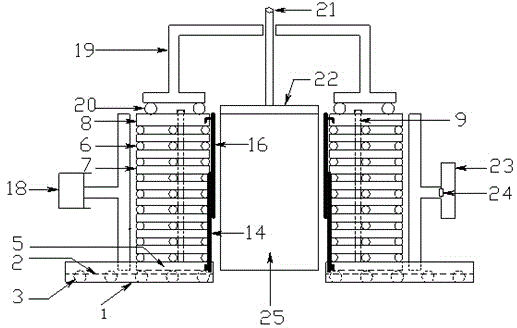

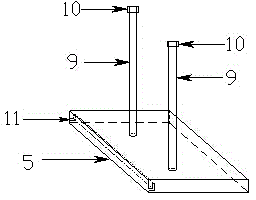

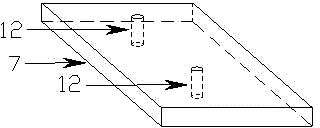

[0019] Such as Figure 1-Figure 3 As shown, an embodiment of the present invention includes a guide rail 2 and a plurality of bearings 3 that are arranged on the guide rail 2 and can rotate on the guide rail 2; The upper pressure plate 8 parallel to the pressure plate 5; a plurality of intermediate pressure plates 7 are arranged in parallel between the lower pressure plate 5 and the upper pressure plate 8; the lower pressure plate 5 and the middle pressure plate 7 Elastic rubber tubes 6 are arranged between, between adjacent middle pressure plates 7, between the upper pressure plate 8 and the middle pressure plate 7; the lower surface of the lower pressure plate 5 is in contact with the test The bottom surface of the sample 25 is on the same horizontal plane; the lower surface of the lower pressure plate 5 is in contact with the bearing 3; the upper pressure plate 8 and the plurality of intermediate pressure plates 7 are provided with at least one through hole 12, vertical Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com