Double-axis vibrating sensor based on flexoelectric principle

A shaft vibration and flexoelectric technology, which is used in vibration testing, instruments, electrical devices, etc., can solve problems such as potential threats to the environment and limited application scope, achieve good low-frequency measurement functions, reduce power requirements, and expand Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

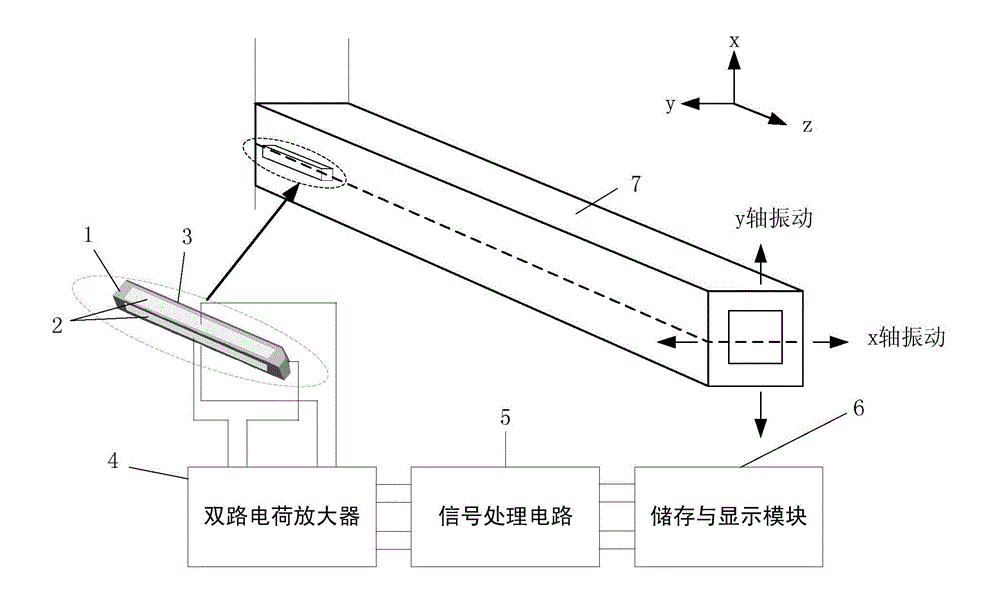

[0032] As shown in the accompanying drawings, a biaxial vibration sensor based on the flexoelectric principle of the present invention includes a sensing unit 1 with a flexoelectric coefficient, and electrodes that are not connected to each other attached to four surfaces along the length direction of the sensing unit 1 2. The sensing unit 1 is connected to the side of the structure to be tested 7 through the epoxy glue 3, the electrode 2 is electrically connected to the dual charge amplifier 4, the dual charge amplifier 4 is electrically connected to the signal processing circuit 5, and the signal processing circuit 5 It is electrically connected with the storage and display module 6 .

[0033] The flexoelectric coefficient of the sensing unit 1 is greater than 10 -10 C / m order of magnitude.

[0034] The sensing unit 1 adopts a mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com