A tube bundle self-supporting heat exchanger

A tubular heat exchanger, self-supporting technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of inconvenient disassembly and maintenance, difficult production and processing, difficult to clean, etc., to achieve installation and Easy to disassemble, eliminate flow dead zone, and not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

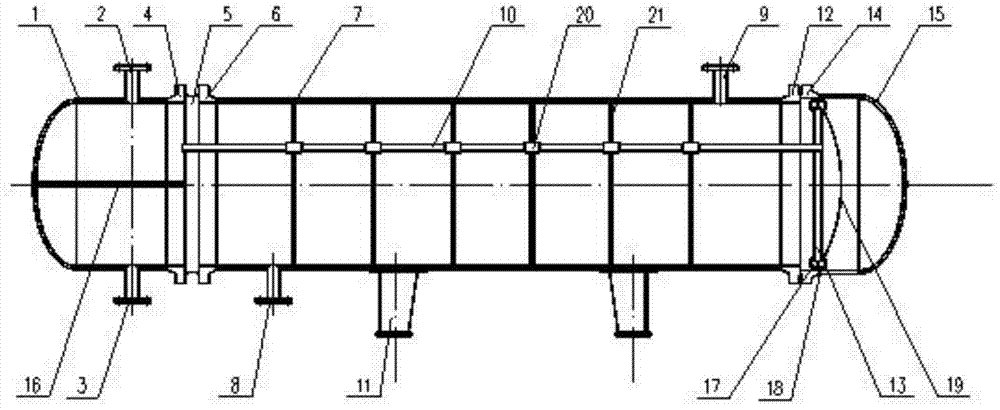

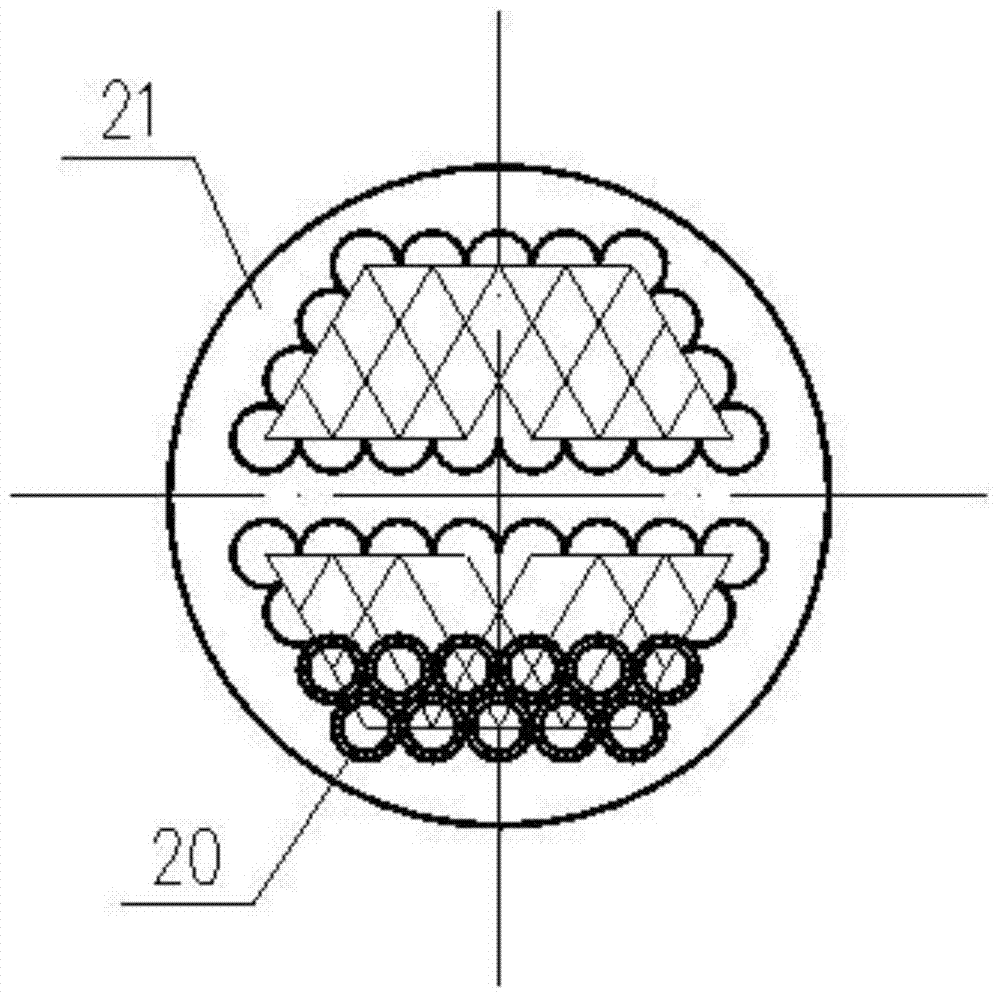

[0022] See figure 1 , is a structural schematic diagram of the present invention, a tube bundle self-supporting heat exchanger of the present invention, including a tube heat exchanger, the heat exchange tube bundle in the tube heat exchanger passes through a single heat exchange tube 10 The fixed sleeves 20 support each other, and the heat exchange tube bundle is supported and fixed by the support plate 21 in the circumferential direction.

[0023] The length of the fixed sleeve 20 is 1 to 1.5 times the length of the nodes of the heat exchange tube 10 , and the fixed sleeve 20 presses grooves adapted to the shape of the heat exchange tube 10 to achieve a tight connection with the heat exchange tube 10 .

[0024] The tube heat exchanger is any one of floating head tube heat exchanger, U-shaped tube heat exchanger or fixed tube-sheet heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com