Integrated double-cooling water chilling unit

A water chiller and double cooling technology, which is applied in the direction of refrigerators, refrigeration components, compressors, etc., can solve problems such as poor operating efficiency, inability to use air conditioners or process occasions, and affect cooling supply, so as to reduce investment and operation costs and achieve high efficiency and energy saving The scope of application, the effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

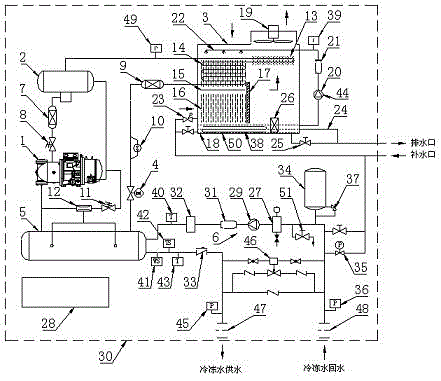

[0022] Such as figure 1 As shown: the integrated double-cooled chiller unit of this embodiment is located in an outer box 30, including a compressor 1, an oil separator 2, a double-cooled condenser 3, an expansion throttling device 4, and an evaporator connected in series. 5 constitutes a closed refrigeration cycle system; the inlet and outlet of the evaporator 5 are provided with a chilled water circulation device 6; the key point is that the double-cooled condenser 3 includes a pool 18 and a spray device 22; the spray The device 22 communicates with the pool 18 through the spray water circulation pump 20 and the first water treatment device 21. The cooling coil 14, the equalizer plate 15, the filler 16, the pool 18, and the double cooling condenser are arranged in sequence under the spray device 22. The top of 3 is provided with cooling fan 19, and the lower part of cooling fan 19 is provided with pre-cooler 13, water receiver 17 successively; Said pool 18 is equipped with f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com