Electro-Pneumatic Integrated Hose Connector

A connector and integrated technology, applied in the direction of hose connection device, connection, connection parts installation, etc., can solve the problems of increasing labor intensity of workers, affecting the safety of train operation, and being easy to be stolen, so as to reduce labor intensity of workers and improve The effect of hanging efficiency and good anti-theft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

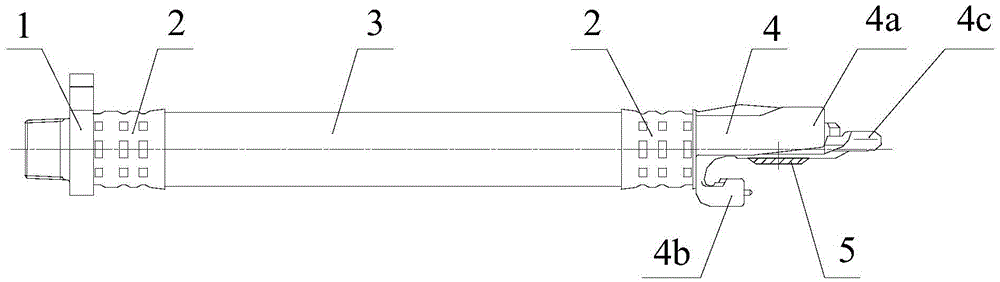

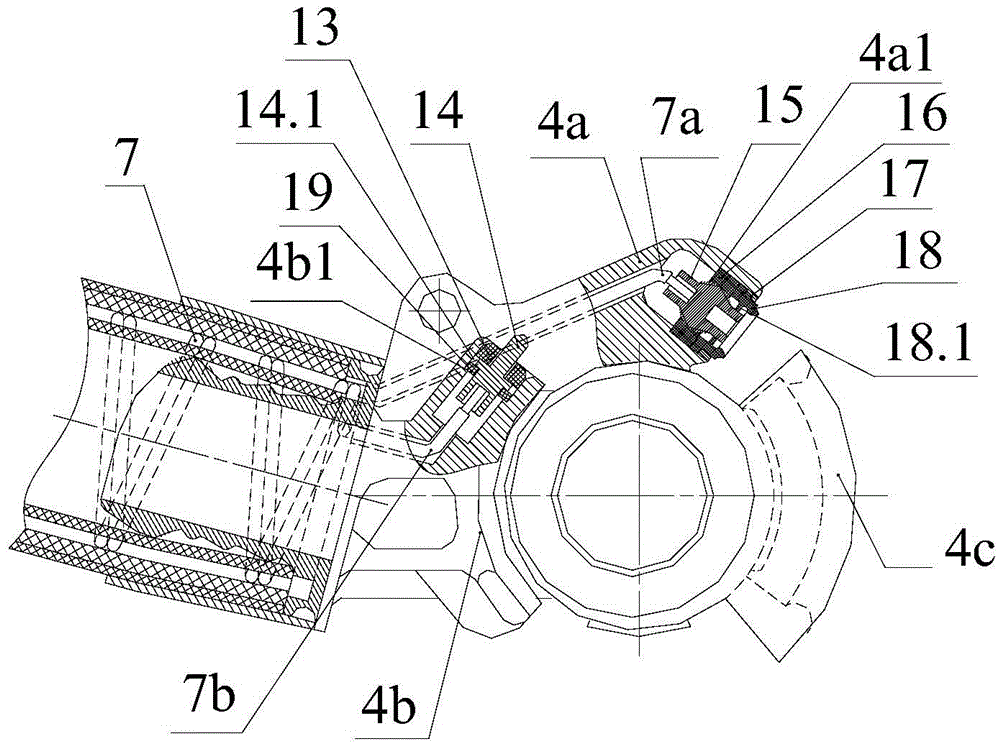

[0026] Such as figure 1 The shown electric-pneumatic integrated hose connector includes a rubber hose 3 , a hollow threaded joint 1 , a hollow connector body 4 and a double-strand cable 7 arranged in the rubber hose 3 . One end of the soft rubber tube 3 is connected to the hollow threaded joint 1 and tightened with a ferrule 2. The other end of the rubber hose 3 is connected to the hollow connector body 4 and tightened with a ferrule 2. and the hollow connector body 4 communicate with each other to form the passage of the air passage. In addition, a hollow hose gasket 5 is placed in the center hole 4.1 of the hollow connector body 4 to realize the sealing of the air passage. The hollow hose gasket 5 is also connected with the hollow hose gasket 5. The connector body 4 communicates.

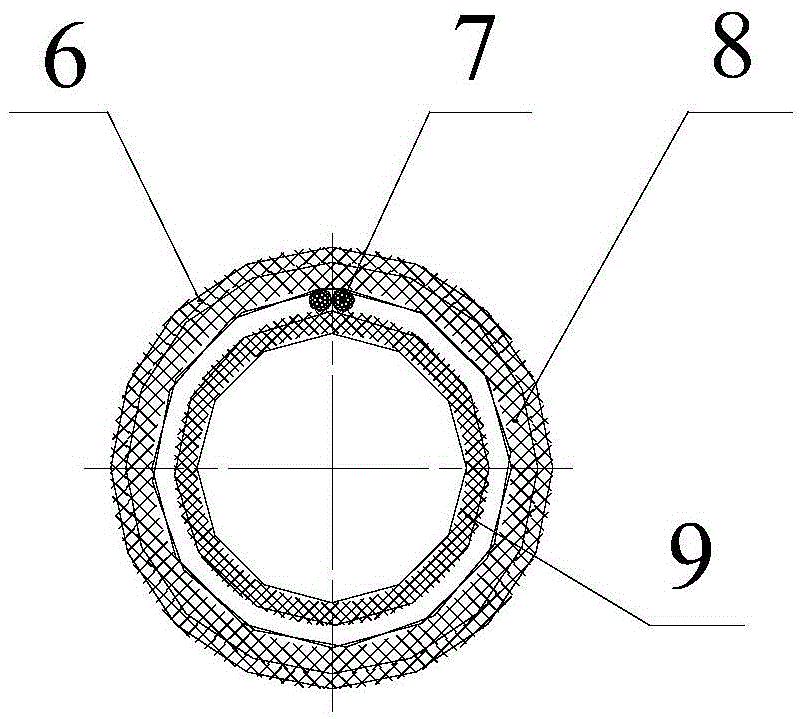

[0027] Such as figure 2 As shown, the rubber ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com