Internal spiral groove oil suction pipe for variable-frequency refrigerator compressor

A technology of internal spiral groove and frequency conversion refrigerator, which is applied in the direction of liquid variable volume machinery, mechanical equipment, machine/engine, etc., can solve the problems of complex assembly process, large oil pump resistance, compressor damage, etc., and achieve simple manufacturing process, The effect of large pump oil resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

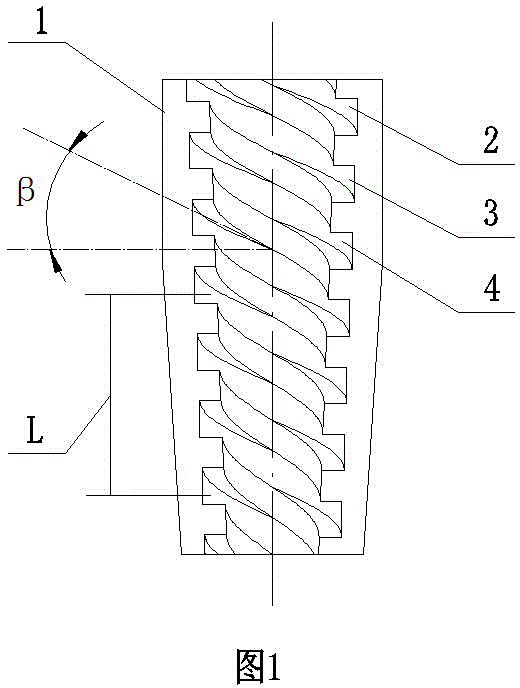

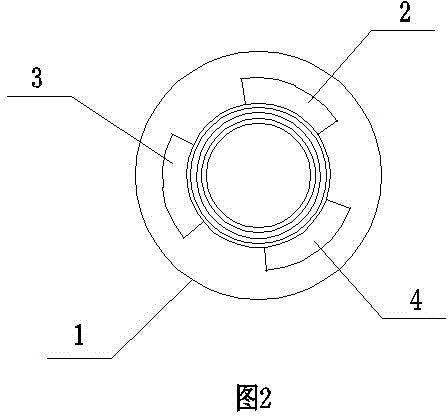

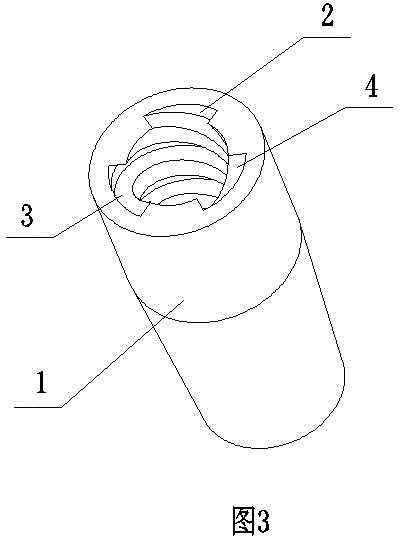

[0015] The inner helical groove oil suction pipe used for the frequency conversion refrigerator compressor is composed of an oil suction pipe body 1 and an embedded inner helical groove. The oil suction pipe body 1 is composed of an upper cylinder and a lower circular frustum. More than one conical internal spiral groove, the embedded internal spiral groove is coaxial with the oil suction pipe body 1, and the cylindrical part of the oil suction pipe body 1 is fixed through the center hole of the motor rotor 6 and then connected to the end surface of the crankshaft 5 .

[0016] The embedded inner spiral groove can be formed by an embedded inner spiral groove a2; it can also be formed by two inner spiral grooves of the embedded inner spiral groove a2 and the embedded inner spiral groove b3; The embedded inner spiral groove a2, the embedded inner spiral groove b3 and the embedded inner spiral groove c4 are composed of three inner spiral grooves.

[0017] When the embedded intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com