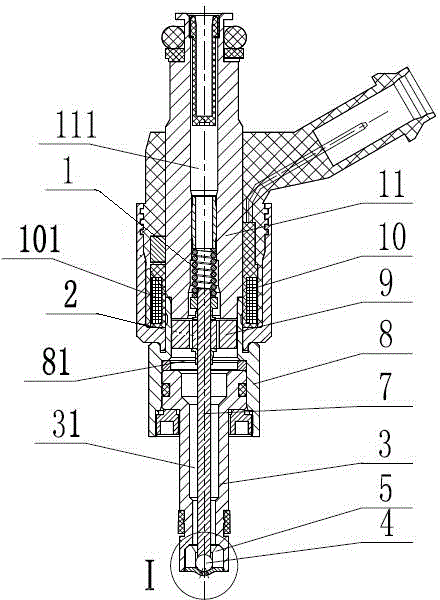

Oil sprayer

A technology of fuel injectors and injection bases, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of increased processing difficulty, slow heat loss, complex structure, etc., to achieve reduced residue or solidification, and low processing difficulty , good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

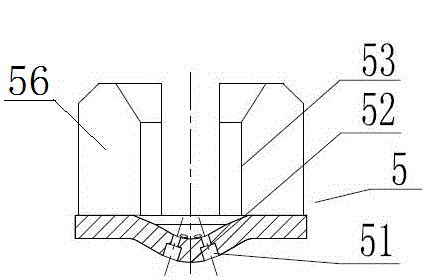

[0029] Embodiment 1: As shown in 4, there are four slots 54, and every two slots 54 are orthogonal to each other.

Embodiment 2

[0030] Embodiment two: if Figure 5 and Figure 6 As shown, there are three slots 54, and the angle between every two slots 54 is 120°.

[0031] The above-mentioned slots 54 that are orthogonal to each other or at an angle of 120° work together with the annular inner surface 53 of the valve wall 56 to form a connected fuel inner passage. The width of the slots 54 is as wide as possible to expand the volume of the fuel passage , so as to reduce the fluid resistance and improve the heat dissipation effect of these parts, but in order to ensure its guiding effect on the ball head 4, the width of the slot 54 should be smaller than the diameter of the ball head 4. The annular inner surface 53 of the valve wall 56 acts as a guide for the ball head 4 . The outer peripheral surface of the valve wall 56 has a certain guiding effect on the inner peripheral surface of the needle valve body 3, which can ensure that when the valve seat 5 and the needle valve body 3 are welded and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com