Conveyor device for drill pipe of deep hole drilling equipment

A conveying device, deep hole drilling technology, applied in drilling equipment, drilling equipment and methods, drilling pipes, etc., can solve problems such as difficult injury risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

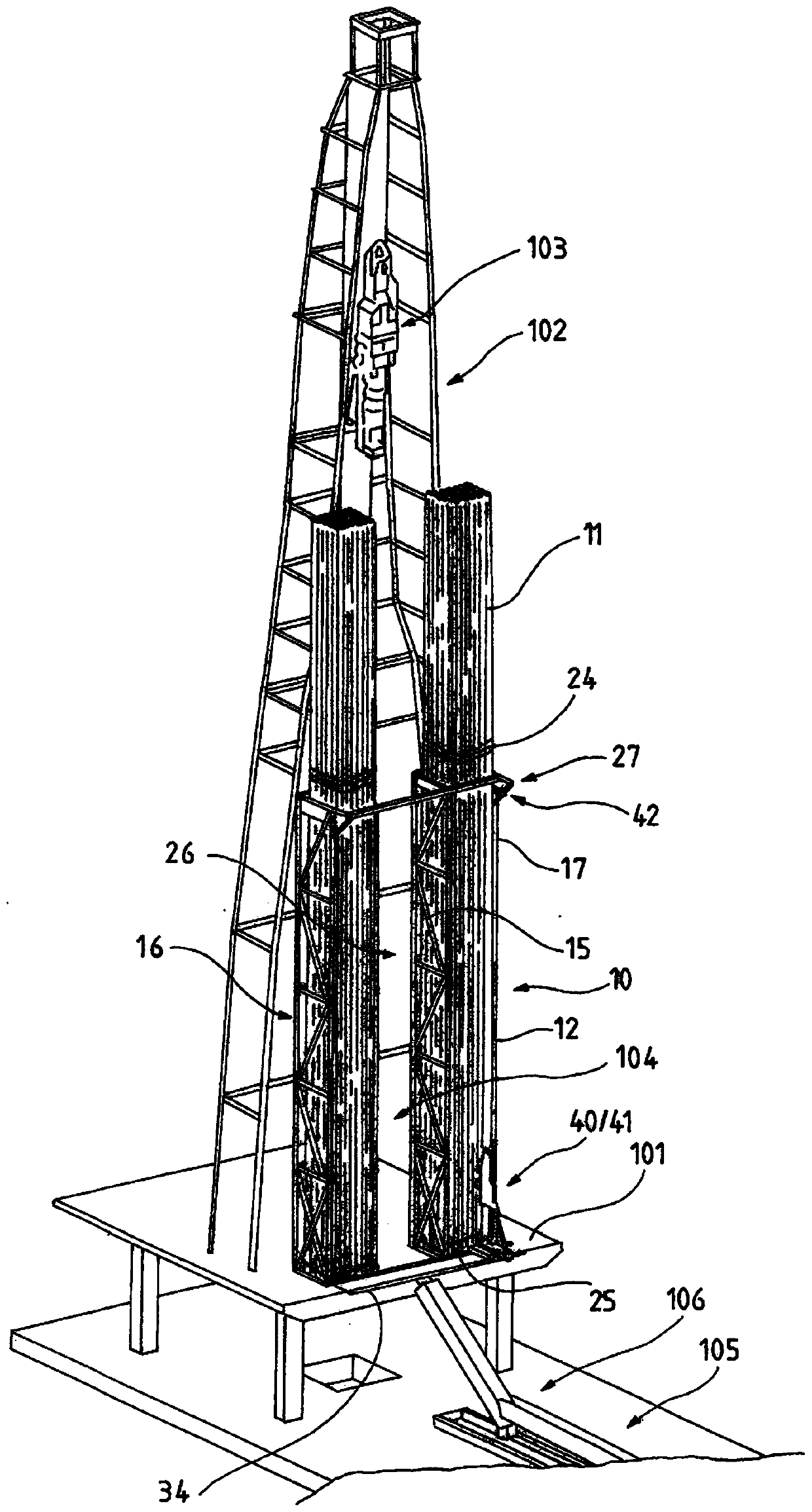

[0051] figure 1 A drilling rig 100 is shown comprising a mast 102 arranged on a working platform 101 in which a so-called top drive 103 is arranged above a so-called well center 104 located above a borehole (not shown). Drilling rig 100 is positioned on wellsite 105 . The catwalk 106 is arranged on the well site 105 and connected with the working platform 101 . A horizontal drill pipe support (not shown) is additionally provided on the wellsite 105 alongside the catwalk 106 for transporting individual drill pipes, casings, drill collars or other drill string components (not shown).

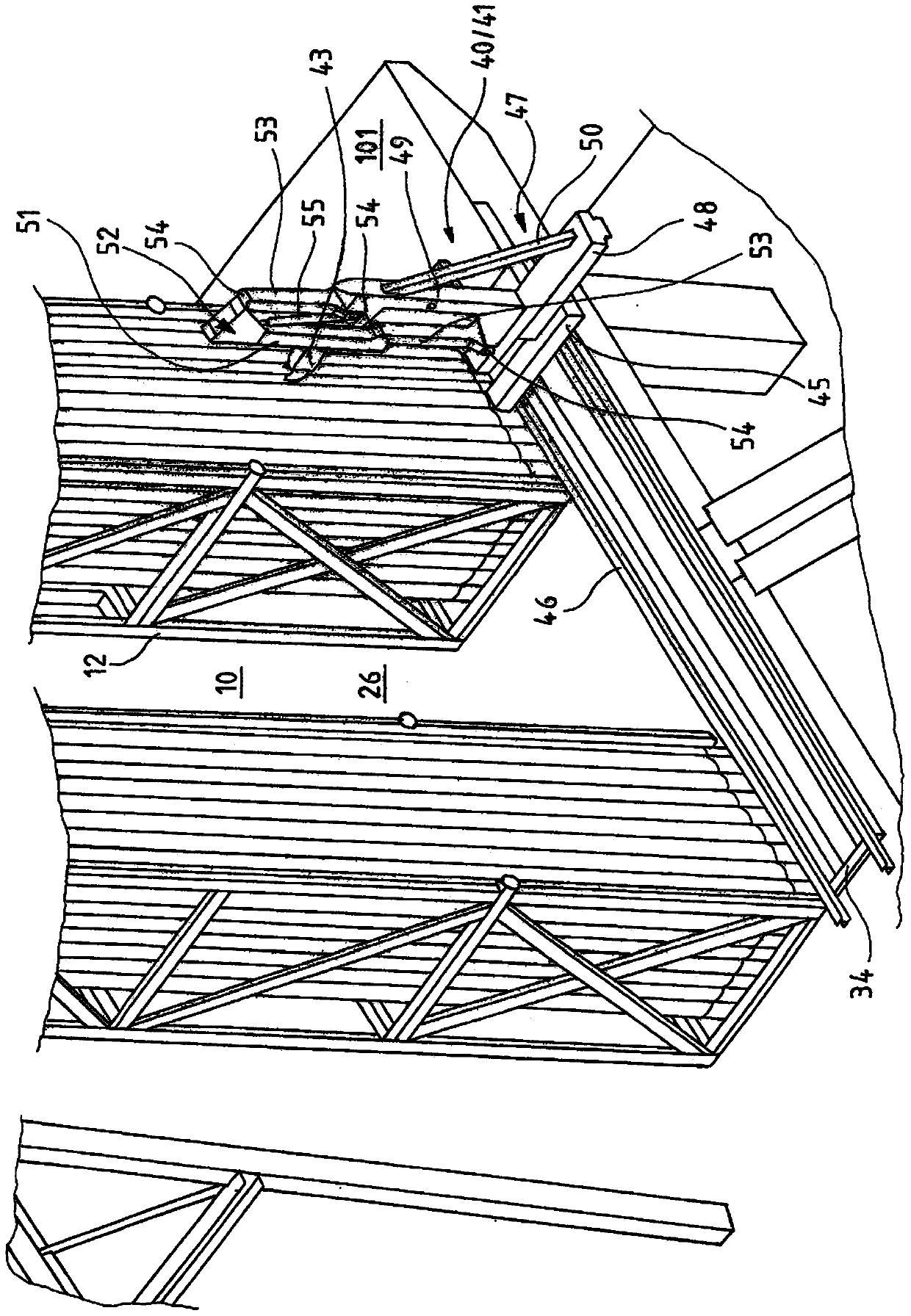

[0052] Parallel to the mast 102 a vertical drill pipe support 10 is arranged. Drill pipes 11 are accommodated in the pipe holder 10 , here in so-called triplets, ie each has three drill pipes 11 screwed together. Groups of two are also fine. Drill pipe support 10 is made up of two such as Figure 2c Shown in the box body 12 that stands up vertically to form. The casing 12 has a bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com