Automatic tube loading device for energy-saving lamp sealing machine

A technology of energy-saving lamps and sealing machines, which is applied in the direction of electric tubes/lights off, machines with sequential working positions, etc., can solve the problems of high work intensity of operators, low production efficiency, inconvenient circulation, etc., and achieve high popularization and application. Value, reduce work intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

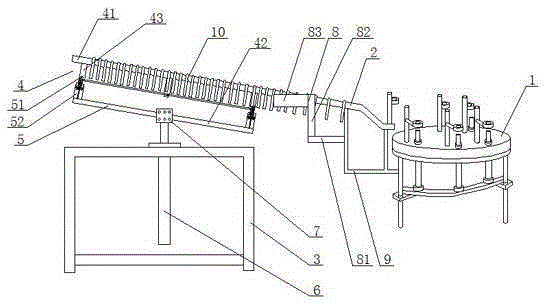

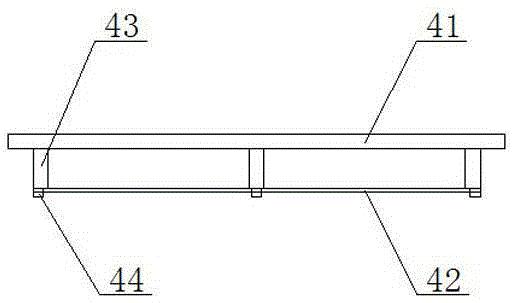

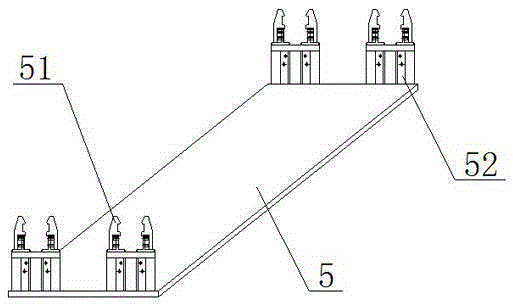

[0020] exist figure 1 , figure 2 with image 3 Among them, the automatic tube loading device of the energy-saving lamp sealing machine includes the host machine 1 of the energy-saving lamp sealing machine. The feeding device of the tube workpiece 10 is provided with an automatic tube loading assembly at the front end of the discharge frame 2. The automatic tube loading assembly includes a frame 3, an inclined chassis 5 is arranged on the frame 3, and a lifting cylinder 6 is fixed under the frame. The lifting cylinder 6 is installed on the frame 3, and the middle part of the chassis 5 is provided with a fixed plate 7. The output shaft of the lifting cylinder 6 is connected with the fixed plate 6, and the inclination of the chassis 5 is guaranteed through the fixing of the fixed plate 6. The pipe device 4, the mobile pipe receiving device 4 includes a sheet-shaped track 41 and a lower shelf 42, the length of the sheet-shaped track 41 is greater than the length of the lower sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com