Automatic feeding and discharging mechanism for production line

A production line and lifting mechanism technology, applied to conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

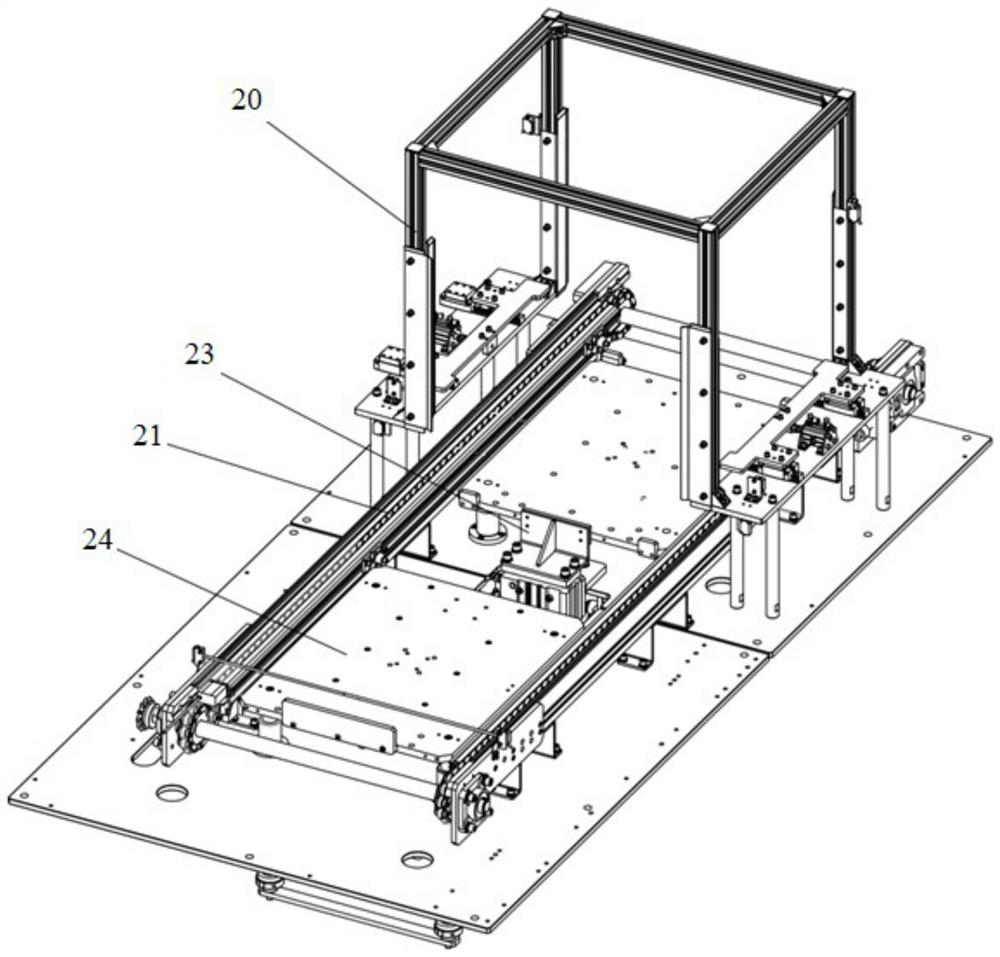

[0027] An automatic loading and unloading mechanism for a production line, which is characterized in that it includes: a frame body 1, a first tray conveying assembly 2, a tray lateral transplanting mechanism 3, a grabbing and unloading assembly 6, and a second tray conveying assembly 5; a first tray The conveying assembly is used for conveying the tray; the two ends of the lateral transplanting mechanism of the tray are respectively corresponding to the first tray conveying assembly and the second tray conveying assembly, and are used for transplanting the tray to the grabbing and unloading material The components correspond to the positions, and the pallets that are loaded and / or unloaded by grabbing the loading and unloading components are transplanted to the first or second pallet conveying components; the second pallet conveying component is used for pallet conveying.

[0028] The first pallet conveying assembly or the second pallet conveying assembly includes: a pallet co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com