Mica type fireproof wear-resisting air-guiding wallpaper

A mica-based, gas-conducting technology, applied in covering/lining, building, building structure, etc., can solve the problems of wallpaper not having fire-extinguishing function, declining wallpaper aesthetics, affecting aesthetic bubbles, etc., to achieve weak conductivity and good electricity. Insulation, easy bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

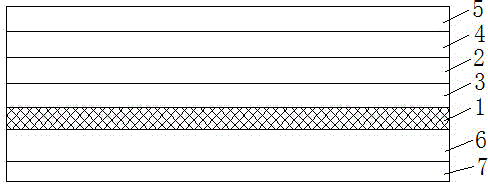

[0014] Such as figure 1 As shown, a mica-type wear-resistant fireproof and air-conducting wallpaper includes a base layer 1, a pattern layer 2, an air-conducting layer 3, a fire-proof light-transmitting film 4, a wear-resistant layer 5, a self-adhesive layer 6 and a release paper layer 7, A pattern layer 2 is arranged on the base layer 1, and an air-guiding layer 3 is arranged under the pattern layer 2. The air-guiding layer 3 is formed by arranging several rows of air-guiding holes, and a layer of fireproof light-transmitting film 4 is arranged on the pattern layer 2. , a wear-resistant layer 5 is provided on the fireproof light-transmitting film 4, a self-adhesive layer 6 is provided below the base layer 1, a release paper layer 7 is provided below the self-adhesive layer 6, and the base layer 1 adopts a mica sheet material, the wear-resistant layer 5 is made of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com